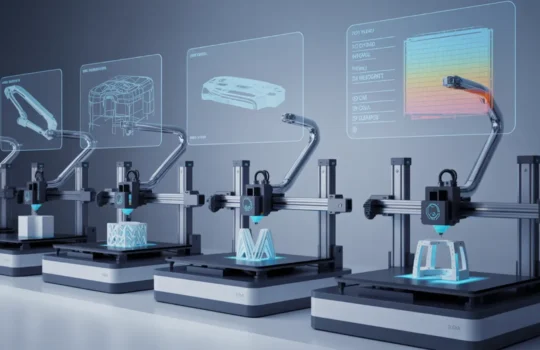

Many companies are changing how they make things. Instead of waiting weeks for parts or keeping big stocks, they now use on-demand 3D printing services. This approach lets them create what they need, when they need it.

With 3D printing, a business can upload a design, pick a material, and have a finished part in just a few days. It saves time, reduces waste, and keeps production flexible.

From car makers to hospitals, more industries are seeing the benefits. They can test ideas faster, customize parts easily, and respond quickly to market changes. On-demand 3D printing is becoming a smarter, faster, and more affordable way to build.

What Are On-Demand 3D Printing Services?

On-demand 3D printing services let companies create parts only when needed. You upload a 3D design, choose the material, and get the part made quickly. There is no need for costly equipment or large storage. This process helps reduce waste, speed up production, and lower costs. It is ideal for prototypes, spare parts, and small product runs. Businesses use it to stay flexible and respond faster to market needs.

Why Industries Are Turning to 3D Printing Services

Lower Costs

Companies are drawn to on-demand 3D printing because it removes high upfront costs. Traditional manufacturing needs expensive molds and tooling, but 3D printing doesn’t. You pay only for what you print. This means less waste, no need for storage space, and better use of capital. Startups and small businesses benefit the most because they can develop products without big investments.

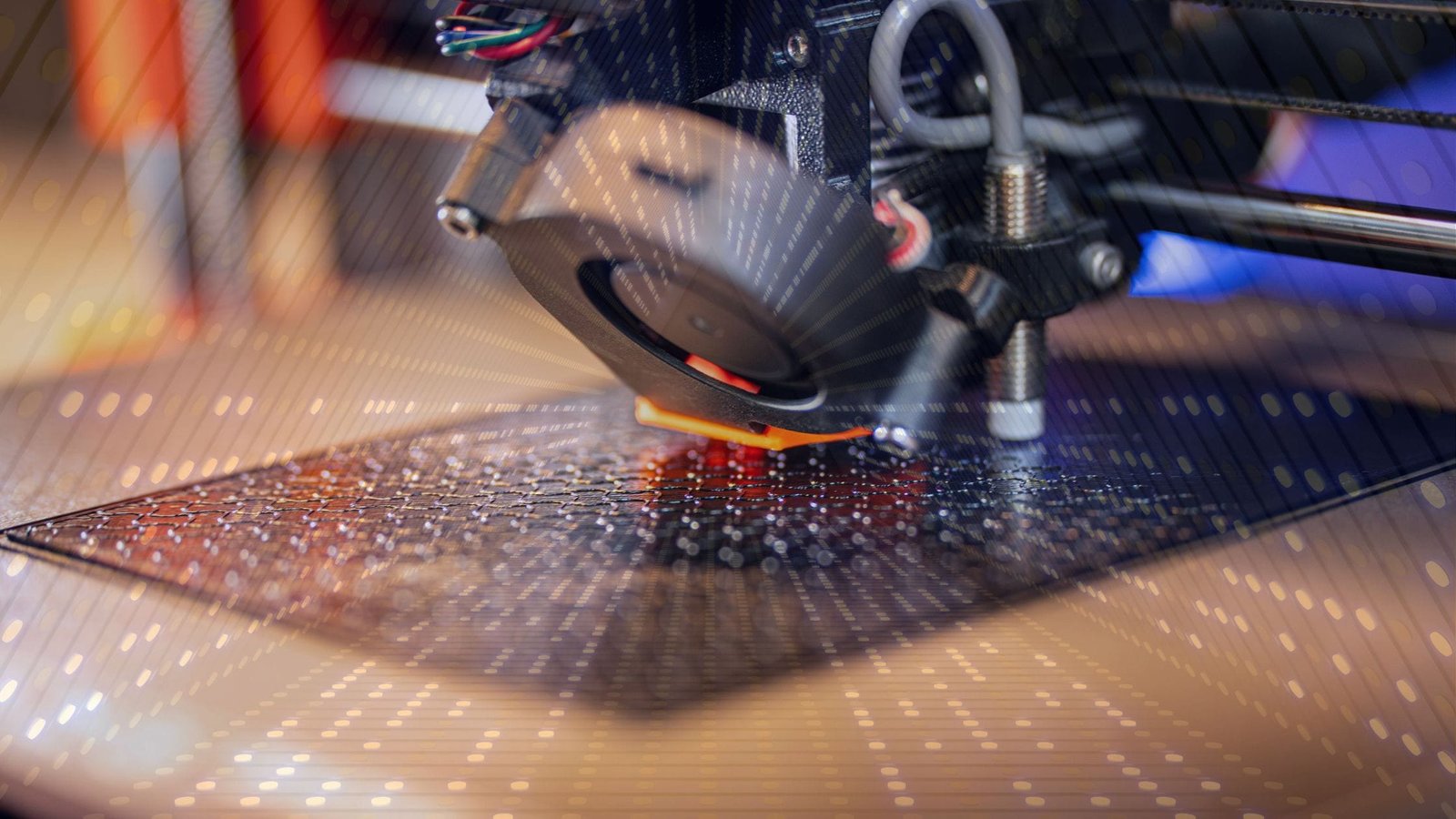

Faster Production

Speed is a major reason industries switch to 3D printing services. What once took weeks can now be done in days. Businesses can design, print, and test parts quickly. This helps shorten product development cycles and speeds up time to market. When companies can move faster, they can adapt to customer needs and stay ahead of competitors.

Customization

Every product or part can be unique. On-demand 3D printing makes it easy to create designs that fit specific requirements. Healthcare uses it to make patient-specific prosthetics. Automotive firms use it for specialized components. This ability to personalize products improves quality and customer satisfaction while keeping production efficient.

Design Flexibility

3D printing allows complex shapes that are difficult or impossible to make with traditional methods. Engineers can change or improve designs instantly without restarting the process. This freedom encourages creativity and innovation. It also makes it easier to improve performance or reduce weight without raising costs.

Sustainability

3D printing helps companies reach their sustainability goals. It uses only the material needed for each part, cutting waste and saving resources. Local production reduces shipping and emissions. Many industries use 3D printing to support cleaner manufacturing and meet environmental standards without sacrificing quality or efficiency.

Supply Chain Strength

On-demand 3D printing gives businesses more control over their supply chains. Parts can be produced locally or regionally when needed, reducing reliance on overseas suppliers. This helps avoid delays caused by transport issues or global disruptions. Companies that use 3D printing can keep production running even when traditional supply chains fail.

Faster Innovation

The technology allows teams to test ideas quickly, learn from results, and adjust designs in real time. It supports a faster product development process, encouraging creativity and experimentation. By reducing the time between concept and prototype, companies can stay ahead of market trends and customer demands.

Scalability

On-demand 3D printing works for single prototypes or small production runs. Businesses can scale up or down based on demand without major setup costs. This makes it ideal for startups testing new markets or established companies producing limited-edition products.

Reduced Risk

Because there are no large upfront investments or long lead times, financial risk is lower. Companies can test designs and make improvements before committing to full-scale production. This approach prevents costly errors and helps ensure product success.

Competitive Advantage

By using on-demand 3D printing, companies gain flexibility, speed, and cost control. They can launch products faster, respond quickly to customer needs, and adapt to changes in the market. These benefits give them a clear advantage over competitors still using slower, traditional methods.

FAQs

Q1. What is the biggest benefit of on-demand 3D printing?

It cuts costs by making parts only when needed, reducing waste and storage needs.

Q2. How fast can parts be printed?

Most parts are completed and shipped within a few days, depending on design and material.

Q3. What materials are available?

Common options include plastics, metals, resins, and composites for different uses.

Q4. Is it secure to share design files?

Yes. Reliable 3D printing services use encryption and NDAs to protect your files.

Q5. Which industries use it most?

Automotive, aerospace, healthcare, and consumer goods rely heavily on 3D printing services for speed and flexibility.

Conclusion

On-demand 3D printing services make production faster, cheaper, and more flexible. They help businesses reduce waste, avoid storage costs, and create custom parts easily. Many industries now use 3D printing to stay efficient and competitive. With the right partner, like Tesseract, companies can turn ideas into real products quickly and affordably.