Fused Deposition Modelling (FDM)

Unlocking Precision

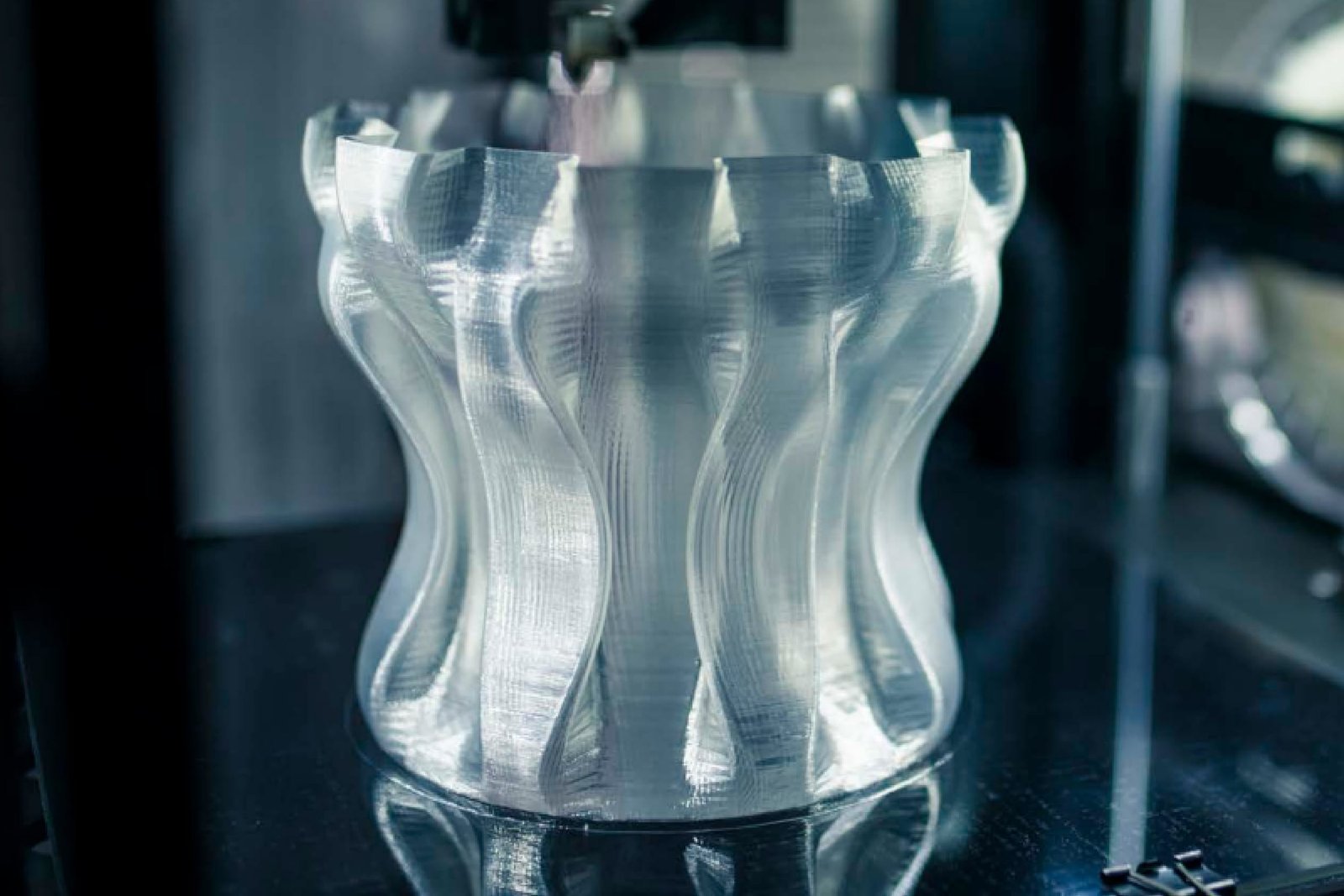

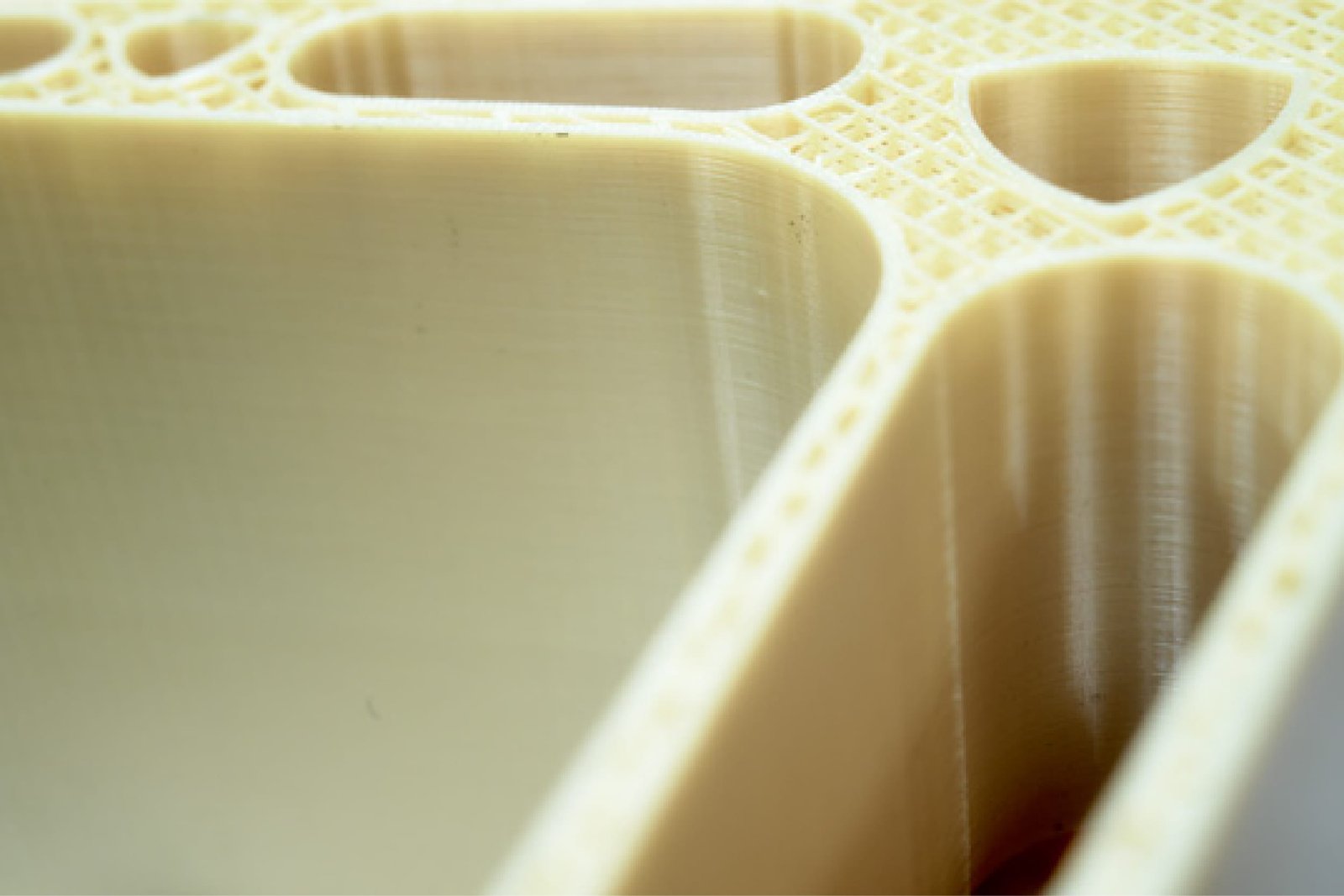

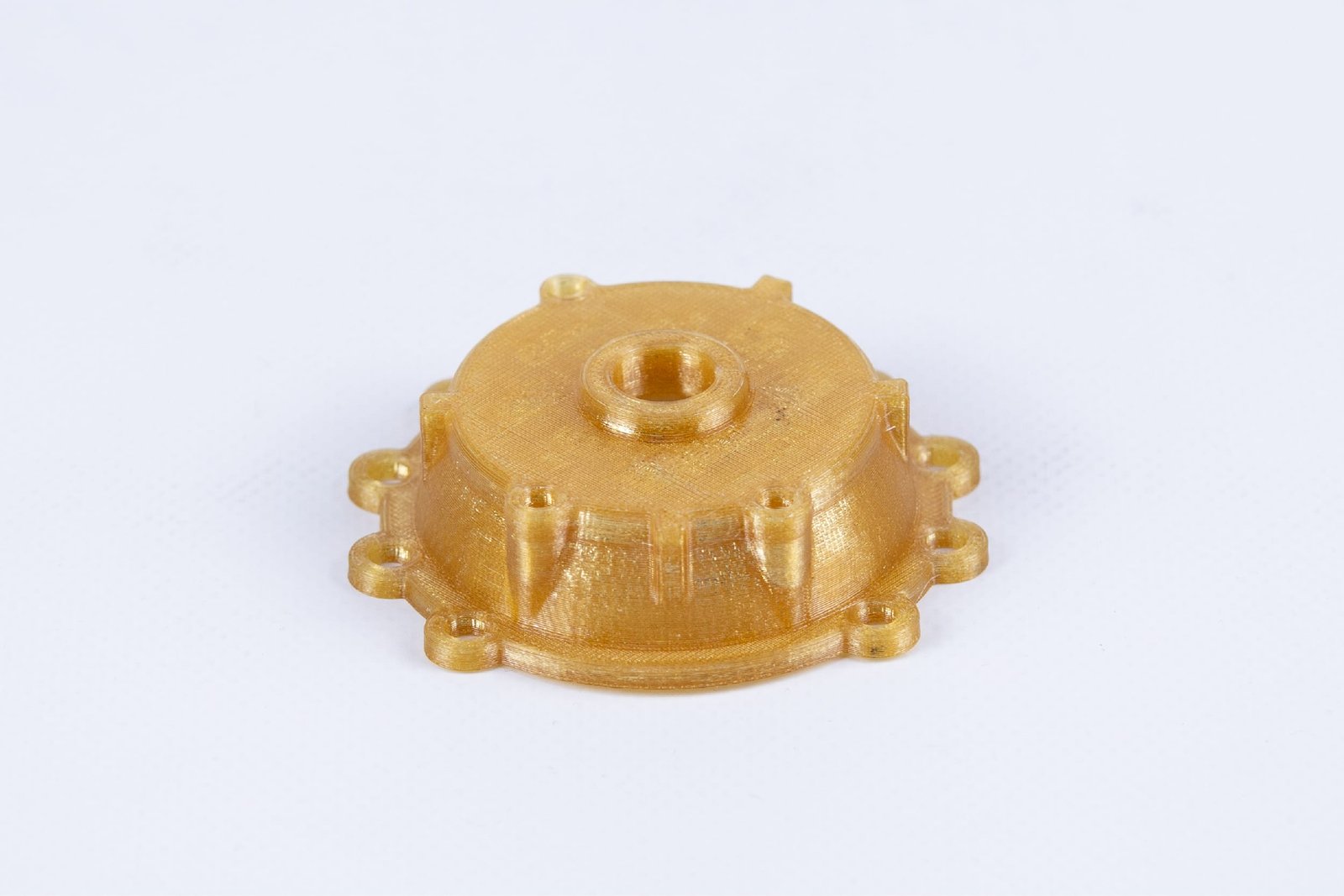

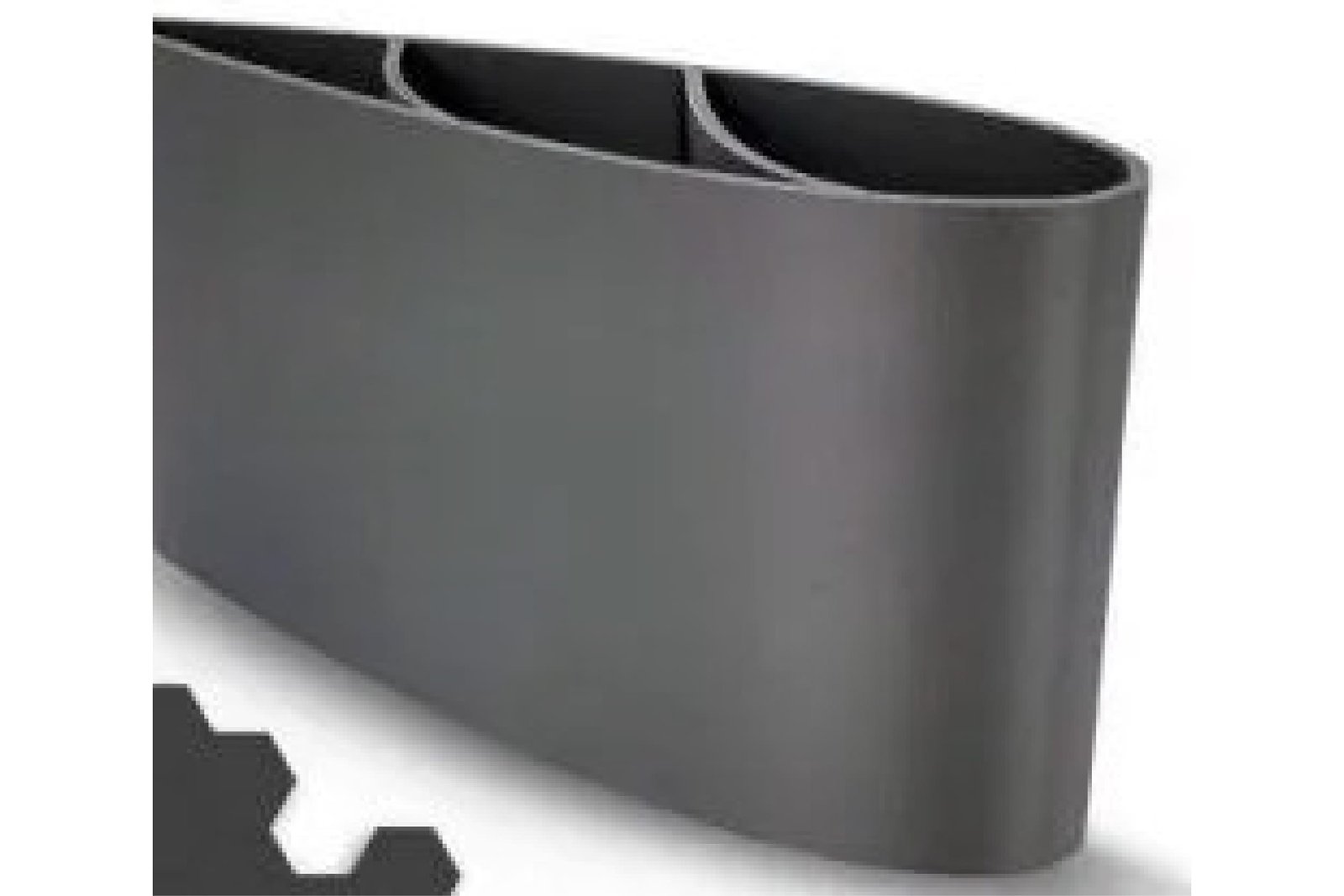

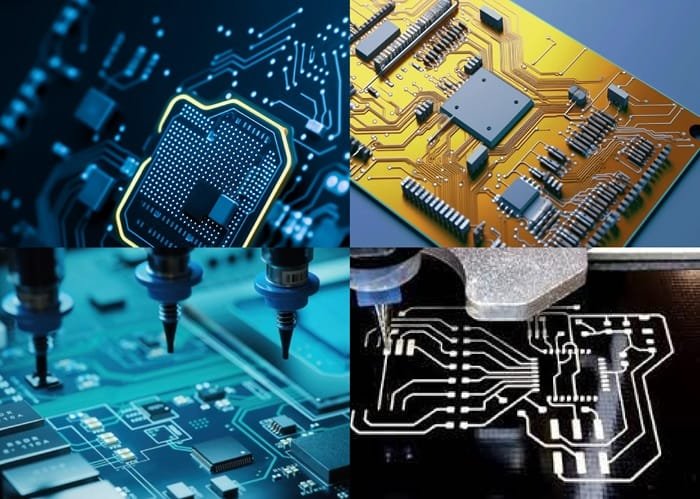

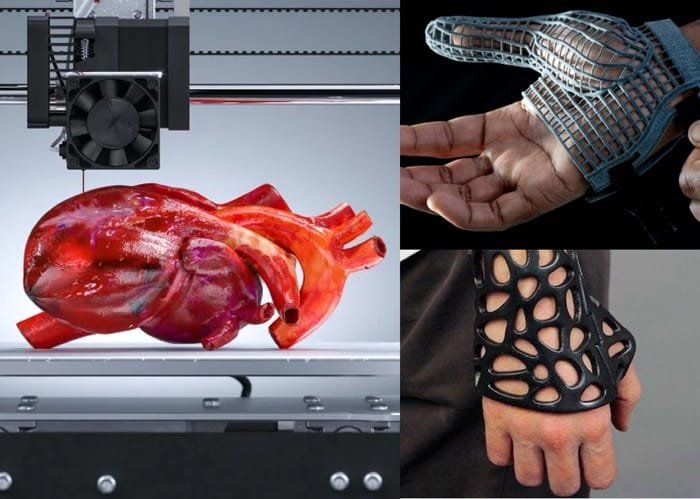

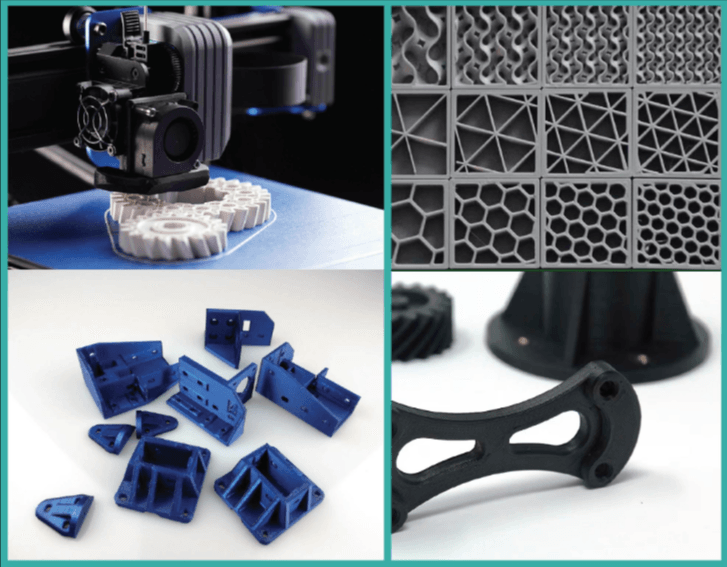

Fused Deposition Modelling (FDM), often referred to as Fused Filament Fabrication (FFF) serves the prototyping and manufacturing demands of diverse sectors. In FDM, the 3D printer heats a thermoplastic filament to its melting point and then selectively deposits it in a predetermined path layer by layer, to create a 3-dimensional object.

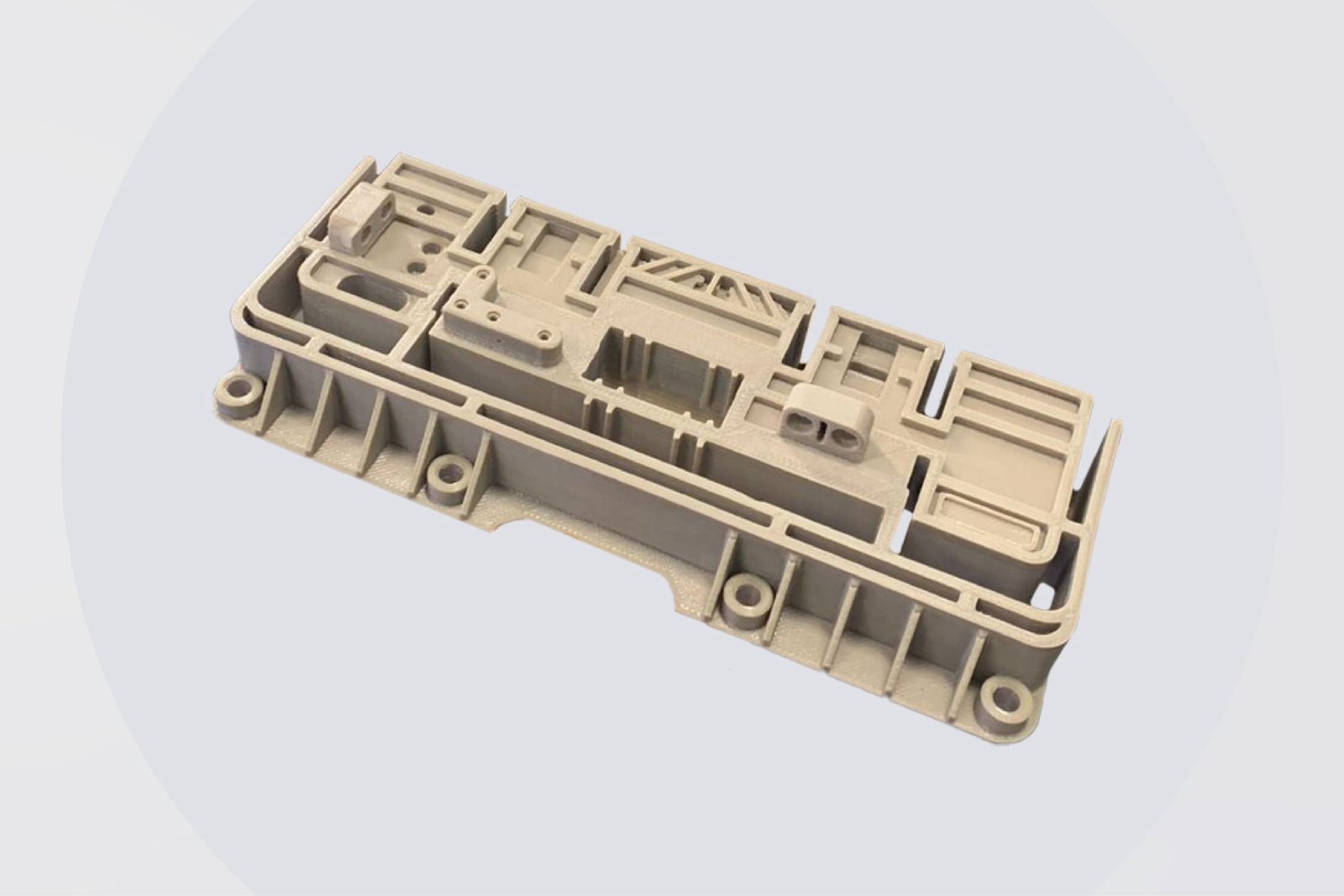

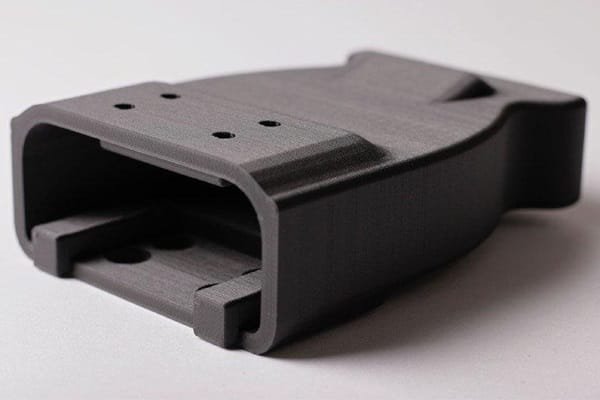

Tesseract proudly houses one of India’s most extensive FDM/FFF 3D Printing facilities, equipped with 100+ high-speed FDM machines of various build volumes. Whether it’s intricate prototypes or life-sized models, our in-house infrastructure delivers professional outcomes at competitive rates.

USP

Cost-Effective Solutions

Rapid Turnaround

Ideal for Testing

Sizeable Printing

Custom Finishes

Material Variety

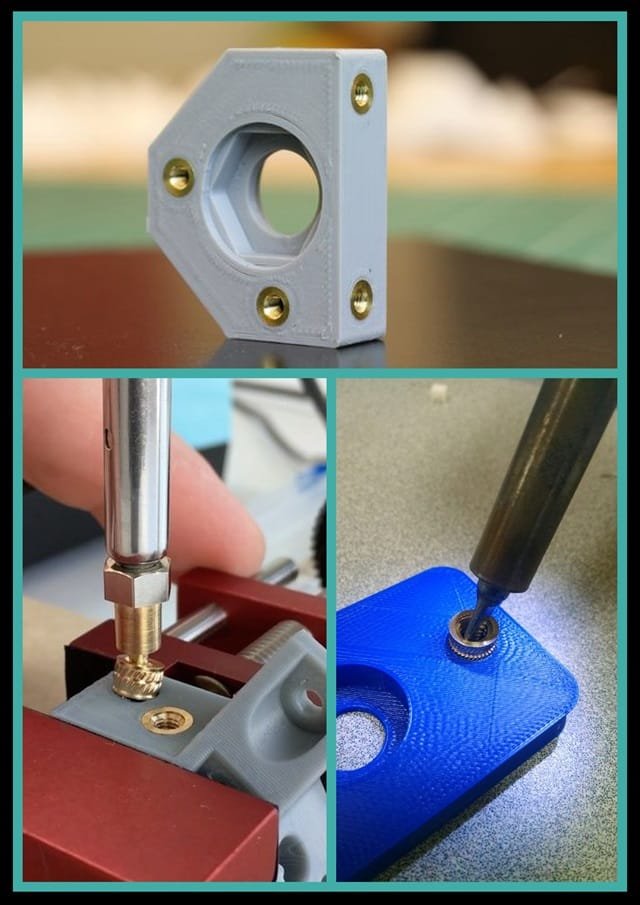

Our Post Processing Offerings

Our Material Offerings

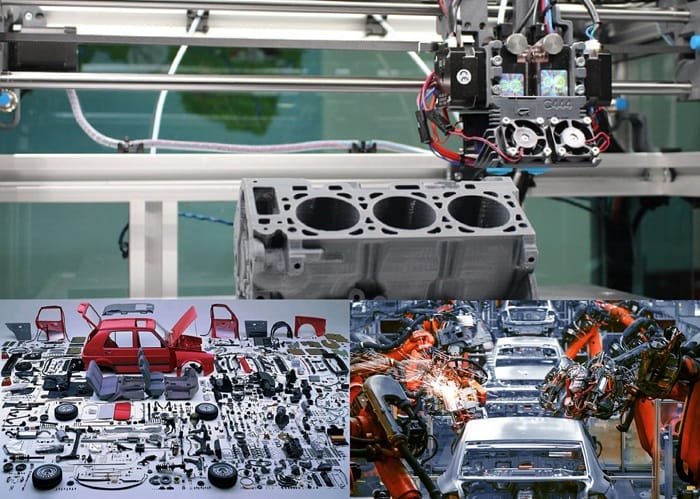

Industries

Why Choose Tesseract for Fused Deposition Modelling (FDM)?

At Tesseract, we pride ourselves on delivering exceptional Fused Deposition Modelling (FDM) services that cater to a wide range of industries. Our commitment to quality, precision, and innovation makes us the preferred partner for all your 3D printing needs. Whether you are looking to prototype a new product, produce intricate parts, or bring your creative ideas to life, Tesseract is here to turn your vision into reality.

Expertise

With over a decade of experience in 3D printing and design, Tesseract boasts a team of highly skilled engineers and designers who are experts in FDM technology. Our extensive knowledge ensures that every project is handled with the utmost care and precision, from concept to completion.

Precision

Precision is at the core of our FDM services. We use state-of-the-art 3D printers and advanced software to create highly accurate and detailed models. Our rigorous quality control processes ensure that every part we produce meets the highest standards of accuracy and reliability.

Innovation

Innovation drives everything we do at Tesseract. We constantly explore new materials, techniques, and technologies to push the boundaries of what is possible with FDM. Our innovative approach allows us to offer unique solutions that are tailored to meet the specific needs of our clients.

Support

At Tesseract, we believe in building strong relationships with our clients. Our dedicated support team is always available to assist, answer questions, and offer guidance throughout the entire 3D printing process. We are committed to ensuring that your experience with us is seamless and satisfactory.

Speed

We understand the importance of time in today’s fast-paced world. Our efficient processes and advanced equipment enable us to deliver high-quality FDM parts quickly and reliably. Whether you need a rapid prototype or a large production run, we ensure timely delivery without compromising on quality.

Choose Tesseract for your Fused Deposition Modelling needs and experience the perfect blend of expertise, precision, innovation, support, and speed. Let us help you bring your ideas to life with our exceptional 3D printing services.

Every project is unique, and so is our approach. At Tesseract, we do not believe in one-size-fits-all solutions. Whether you are an engineer, an architect, a product developer, or a startup venturing into wearables, our bespoke design process is designed to align perfectly with your unique needs and aspirations.

Our vast experience across various industries enables us to provide insightful guidance and support throughout your product development journey. Our team aids in making informed decisions that ensure your product is viable and primed for success. Our clientele includes professionals from diverse sectors including engineering, architecture, automotive, Internet of Things (IoT), sculpture, and innovative startups.

Turning sketches and 2D drawings into fully realized 3D models is our forte. Utilizing advanced modelling software and innovative design techniques, we transform your initial drawings into 3D creations that are not only accurate but also optimised for further development and production processes. This simplification and enhancement of the design process facilitate a smoother progression from the drawing board to market readiness.

- Expertise: With deep industry knowledge and advanced technological capabilities combined, our team brings a wealth of experience to every project. Our seasoned professionals have a track record of delivering top-notch designs across various industries, ensuring your vision benefits from the best in the field.

- Precision: At Tesseract, we are detail-oriented, focusing meticulously on each aspect of your design. Our commitment to precision ensures that every product we develop is an accurate match to your specifications, eliminating errors and enhancing functionality.

- Innovation: We pride ourselves on our forward-thinking approach, using state-of-the-art design techniques to push the boundaries of possibilities. Our innovative mindset means we constantly explore new methods and technologies to bring your ideas to life in the most effective way.

- Support: From the initial concept to the final product, our dedicated team is with you every step of the way. We provide comprehensive support, ensuring you have all the guidance and expertise needed throughout the product design process, making your journey smooth and stress-free.

- Speed: Our efficient processes are designed to expedite your project from concept to reality swiftly. We understand the importance of time in product development, and our streamlined approach ensures quick turnarounds without compromising on quality.

Embark on your product development journey with Tesseract, where your visions are transformed into groundbreaking realities. Connect with us today to see how your ideas can take shape in the world of tomorrow!