Metal Casting

Unlocking Moulding

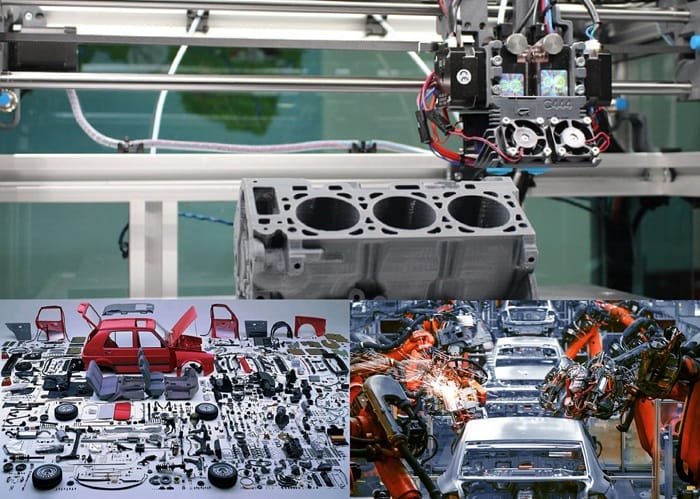

Metal Casting is a versatile manufacturing process that transforms molten metal into 3D pieces. With custom moulds, it offers a vast range of shapes and sizes for your metal needs. The process begins with pattern making, where a model of the final part, crafted from materials like wood, metal, plastic, or created through techniques like machining or 3D printing, is prepared. Next, moulds are created using these patterns, which can be reusable or expendable, depending on the project. When everything is set, metal is melted and poured into the mould cavity. The most common metals used include steel, stainless steel, aluminium, copper, magnesium, and zinc. After cooling and solidification, the final casting is removed and undergoes finishing processes such as filing, cleaning, and polishing. Optional machining and drilling can also be performed to achieve the desired specifications.

USP

High Volume Production

Precision & Efficiency

Versatility