Injection Moulding

Unlocking Scalability

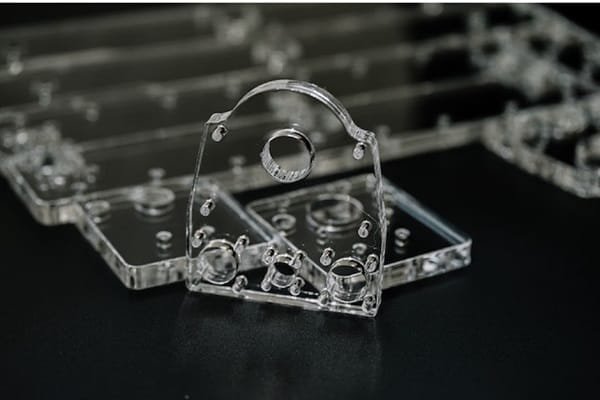

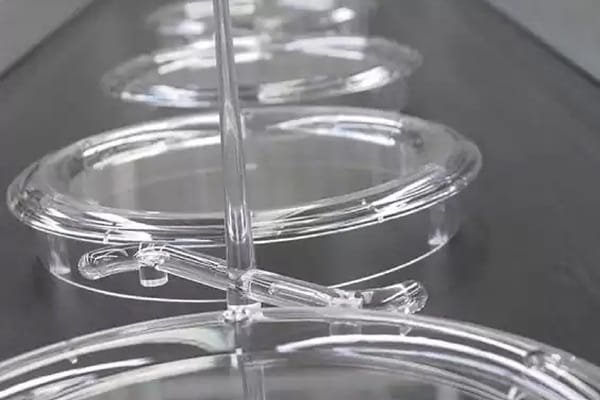

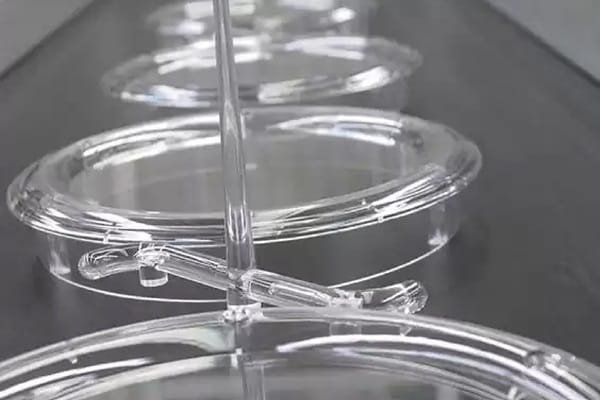

Injection moulding is a versatile manufacturing process used to create parts by injecting molten material into moulds. This method can be employed with a wide range of materials, with thermoplastics and thermosetting polymers being the most common. Designing plastic parts involves considering various factors, including functionality, structural integrity, and the moulding process itself. Following fundamental principles of injection-moulded part design leads to parts that are easier to produce, assemble, and offer enhanced durability. Injection moulding is the preferred method for manufacturing plastic components in large quantities.

USP

High Volume Production

Enabling large quantities

High Tolerance Precision

Accurate results with minimal deviations

Repeatability

Reliable and consistent outcomes

Wide Material Selection

Broad range of choices

Cost Effective

Minimal scrap losses and reduced post processing

Biocompatibility Certifications

USP Class VI & ISO 10993 compliant, supports ETO & Gamma Sterilisation