3D Scanning & Reverse Engineering

Unlocking Innovation

Explore the boundless possibilities with our 3D Scanning and Reverse Engineering services, where innovation meets precision.

3D Scanning & Reverse Engineering can unlock the potential of physical objects. It begins with meticulous measurement, aiming to reconstruct the precise design, intent of the object. Traditionally, reverse engineering was conducted with manual measurements. However, 3D Scanning has revolutionised this process by providing precise data, handling intricate parts with millions of measured points, faster data capture, comprehensive depiction of wear and deviations, and convenient portability for scanning in various locations.

Our USP

High-Level Accuracy

Versatility

Vast Experience

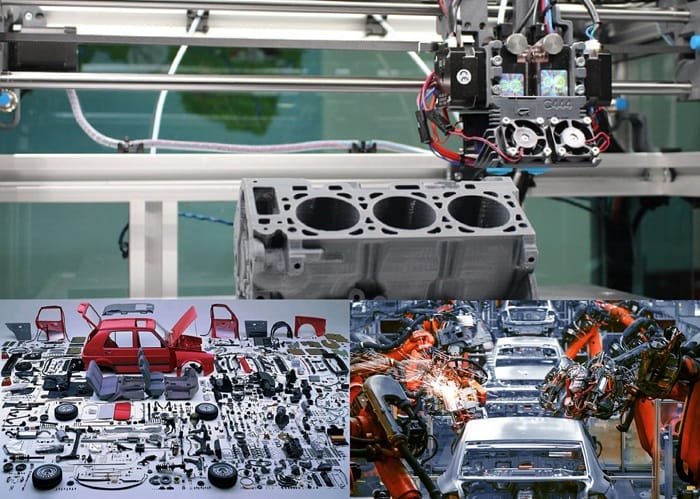

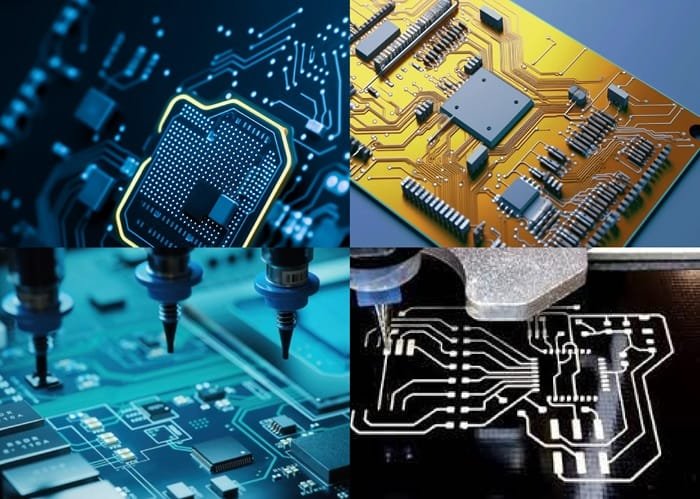

Applications

- Replacement & Upgradation: Replacing damaged components and updating obsolete parts for enhanced efficiency

- Integration & Analysis: Fitting new parts into existing assemblies and analysing competitor’s product features

- Inspection & Simulation: Inspecting manufactured parts and conducting software-based simulations for various parameters

- Design Optimisation: Optimising the design process for superior aftermarket products and new manufacturing plans

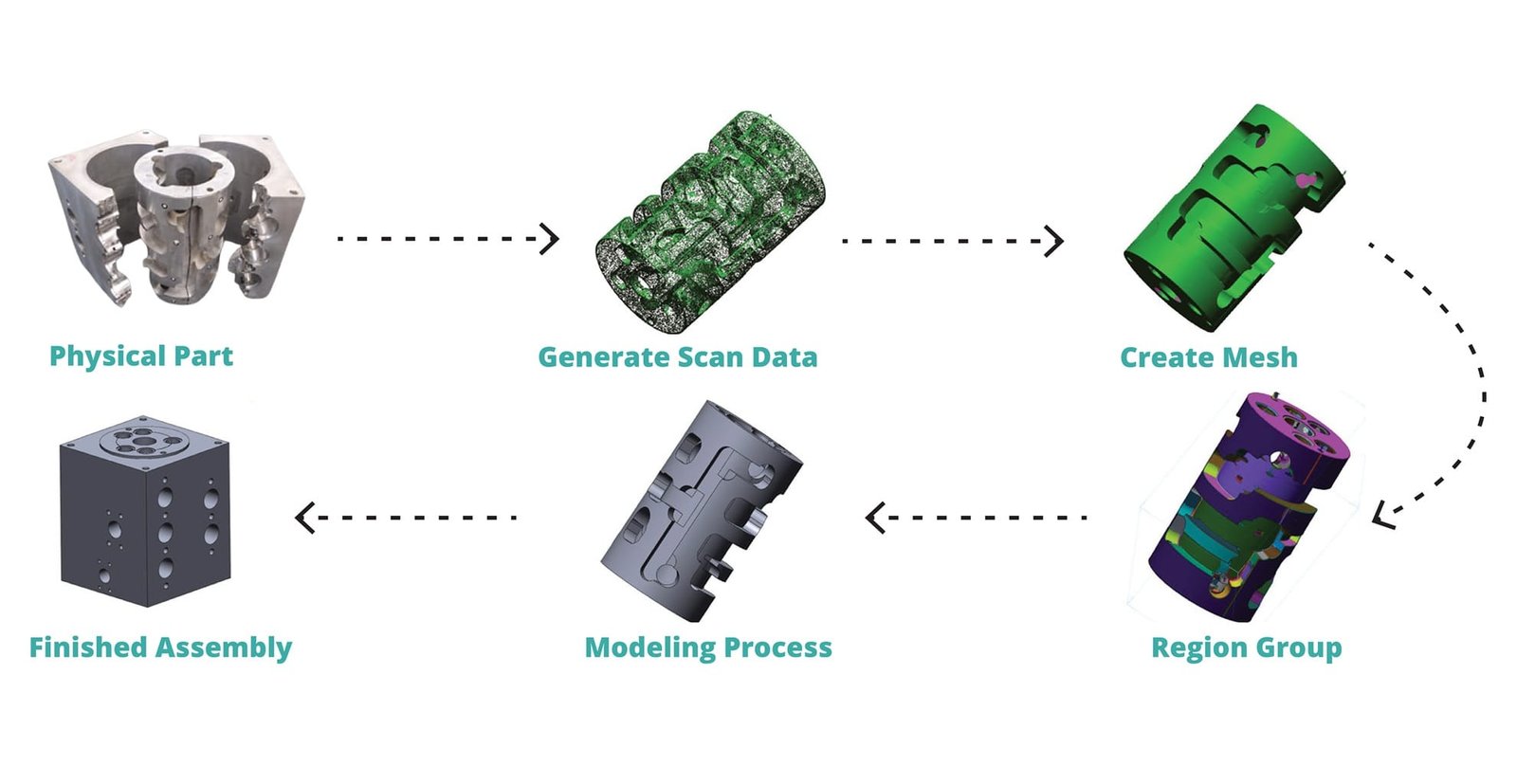

Our Process

Transforming products to digital models through 3D Scanning & Reverse Engineering

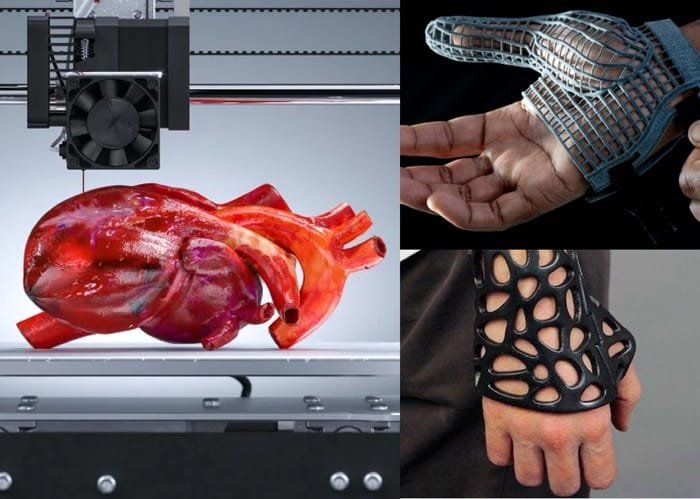

Industries

Why Choose Tesseract for 3D Scanning and Reverse Engineering?

We are committed to delivering exceptional 3D scanning and reverse engineering services at Tesseract, leveraging our state-of-the-art technology and extensive industry experience. Whether you’re looking to recreate complex geometries or streamline your production process, Tesseract is your go-to partner for achieving precision and excellence.

Our Unique Selling Points:

HIGH-LEVEL ACCURACY:

We utilize advanced scanning equipment and software to capture every detail precisely. This level of accuracy is essential for creating exact replicas and ensuring compatibility in reverse engineering projects.

VERSATILITY:

Our services are adaptable to various industries, including aerospace, automotive, healthcare, and consumer products. No matter the complexity or scale of your project, Tesseract can tailor solutions to meet your specific needs.

INNOVATION

Innovation is at the heart of what we do. We continuously invest in the latest technologies and methodologies to stay ahead of the curve, providing cutting-edge solutions that drive your projects forward.

SUPPORT:

Our team of experts is dedicated to providing comprehensive support throughout your project’s lifecycle. From initial consultation to final delivery, we ensure seamless communication and collaboration, addressing any challenges promptly and effectively.

SPEED:

We understand the importance of time in today’s fast-paced market. Our efficient processes and quick turnaround times enable us to deliver high-quality results without compromising on precision or detail.

VAST EXPERIENCE:

With years of experience in the 3D scanning and reverse engineering industry, Tesseract has built a reputation for excellence and reliability. Our extensive portfolio of successful projects speaks volumes about our capability and commitment to quality.

Choose Tesseract for your 3D scanning and reverse engineering needs and experience the perfect blend of technology, innovation, and expertise. Let us help you bring your vision to life with precision and efficiency.