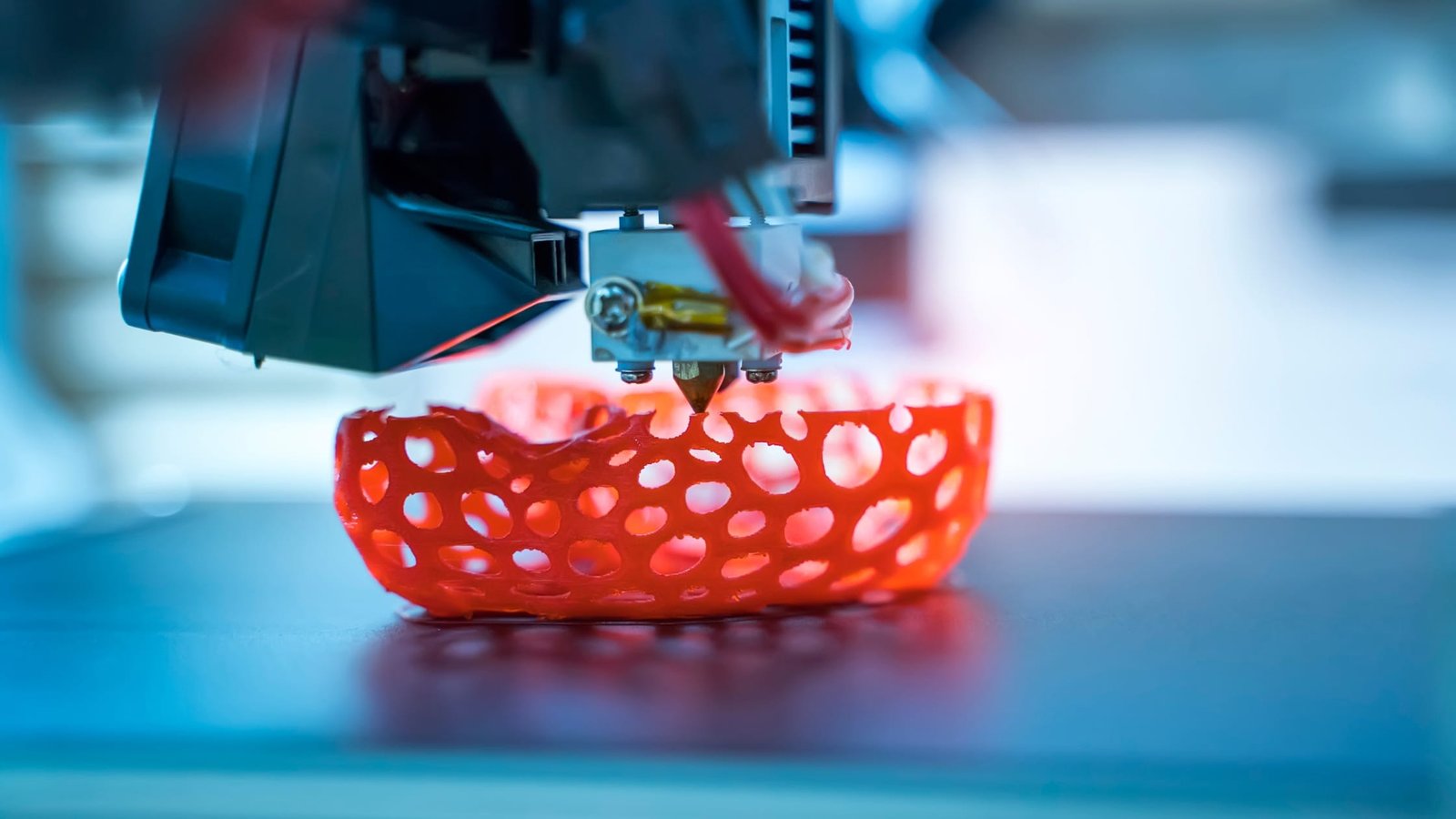

Healthcare in India is undergoing a massive transformation, and 3D printing is at the forefront. 3D printing in medical devices is making personalized healthcare accessible to millions. From ₹5,000 prosthetics to custom surgical implants, this technology is democratizing medicine across Indian hospitals. The market is booming, and devices that once cost lakhs are now affordable.

In this post, you’ll discover which medical devices can be 3D printed in 2026 and how this breakthrough is saving lives while reducing costs.

Why 3D Printing is Changing Healthcare

3D printing in healthcare offers benefits that traditional manufacturing cannot match. The technology enables personalized treatment tailored to each patient’s anatomy, speeds up production, reduces cost, and supports sustainable healthcare with on-demand manufacturing.

Medical Devices You Can 3D Print in 2026

Here are the medical devices being 3D printed today and expected to expand in 2026.

1. Prosthetics and Orthotics

Custom-fit artificial limbs are becoming more accessible. These lightweight prosthetics improve mobility and cost up to 60% less than traditional options. Adjustments and replacements are fast and affordable.

2. Surgical Instruments

Surgeons now use 3D printed scalpels, clamps, forceps, and patient-specific guides. These tools enhance precision during surgeries and lower infection risks due to disposable sterile options.

3. Dental Devices

3D printing is widely used in dentistry. Crowns, bridges, aligners, and dentures are produced faster and fit more accurately. Implant guides improve surgical precision and patient comfort.

4. Anatomical Models

3D printed anatomical models help surgeons plan complex procedures. Medical students use them for training, and patients understand their conditions better through visual explanation.

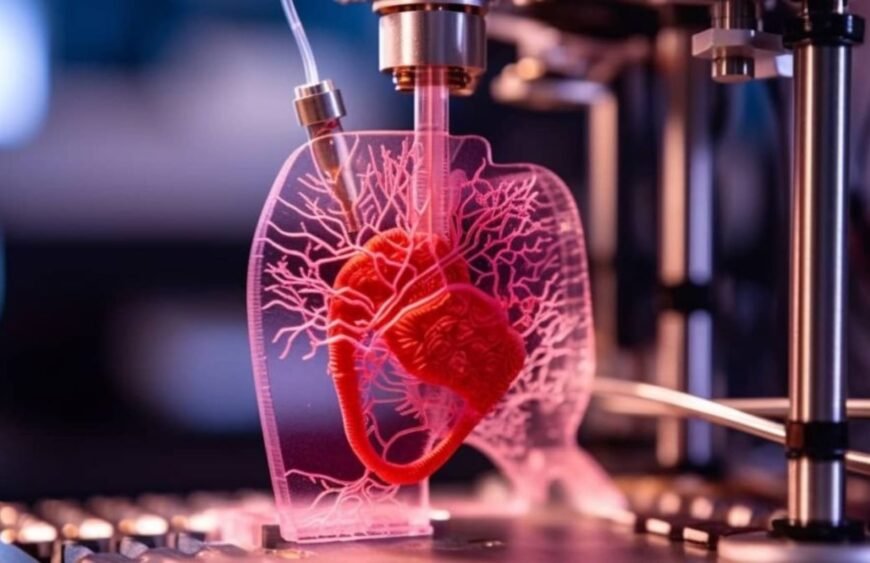

5. Implants

Hip, knee, and spinal implants are now commonly 3D printed. Cranial plates and bone scaffolds provide perfect anatomical fit and support natural healing.

6. Hearing Aids

Custom ear molds and behind-the-ear devices offer improved comfort and sound quality. Production time has reduced from weeks to days.

7. Drug Delivery Systems

Pharma companies are printing personalized pills with precise dosages and controlled-release mechanisms. These customized designs improve drug absorption and treatment efficiency.

8. Respiratory Devices

3D printed CPAP masks fit perfectly, preventing air leaks. Ventilator parts and oxygen delivery components can be produced quickly during emergencies.

Frequently Asked Questions

Q1: Is 3D printing in medical devices safe?

Yes. Devices approved by CDSCO and FDA follow strict safety standards and use biocompatible materials.

Q2: How much do 3D printed medical devices cost in India?

Prosthetics start from ₹5,000, while implants cost between ₹50,000 and ₹2 lakhs—40–60% cheaper than traditional devices.

Q3: Which Indian hospitals use 3D printing?

AIIMS, Apollo, and Fortis lead the way, while many tier-2 hospitals are adopting the technology through partnerships.

Q4: How long does it take to 3D print a device?

Surgical guides take 2–4 hours, while complex implants require 2–3 days including design and finishing.

Q5: Can 3D printed devices be customized?

Absolutely. Customization is the biggest advantage, ensuring better comfort, fit, and clinical outcomes.

3D Printing is Transforming Medical Care

3D printing in medical devices is no longer futuristic—it’s a reality. From prosthetics to implants, eight major categories can be 3D printed in 2026. This innovation is improving patient outcomes and making healthcare more affordable across India.

Ready to explore how 3D printing can transform your medical device manufacturing? Contact Tesseract today to learn more.