In recent years, 3D printing has evolved from simple plastic prototypes to creating strong, usable parts from metal. One of the most popular technologies leading this change is Direct Metal Laser Sintering (DMLS). It allows manufacturers to create complex, high-performance parts quickly and efficiently. In this blog, we’ll explain what DMLS is, how it works, and when it’s the right choice for your project.

What is Direct Metal Laser Sintering (DMLS)?

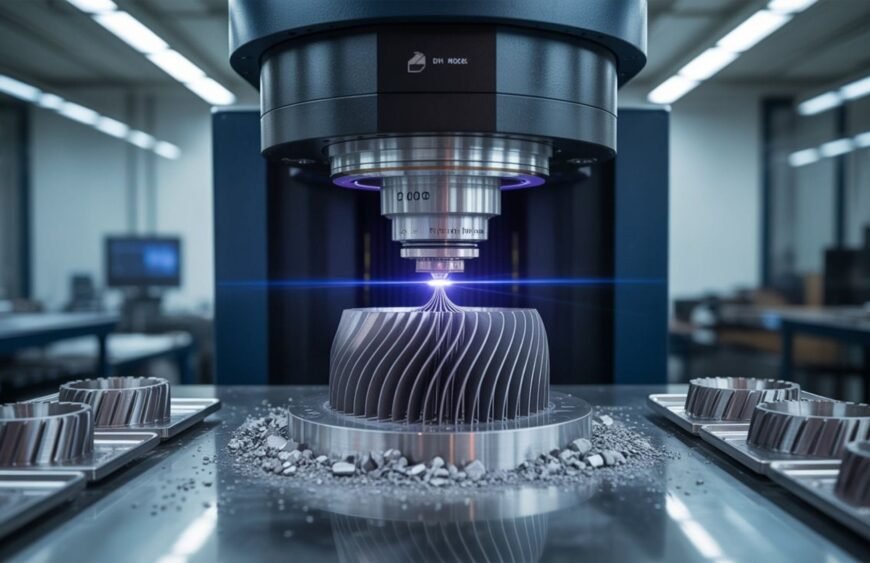

Direct Metal Laser Sintering (DMLS) is a type of 3D printing that builds metal parts by fusing layers of metal powder using a powerful laser. Instead of melting plastics, DMLS uses fine metal powders like stainless steel, titanium, or aluminum to produce solid metal objects directly from a digital file.

How DMLS Works – A Quick Breakdown

The process starts with a 3D CAD model of your part. This model is sliced into thin layers, and the DMLS printer lays down a thin layer of metal powder. A laser then scans the surface, heating and fusing the powder into a solid. This process repeats layer by layer until the part is complete. After printing, the part may go through heat treatments or finishing processes depending on the application.

Key Advantages of DMLS

Design Freedom and Complex Geometries

DMLS makes it possible to print shapes that are impossible or very expensive to produce with traditional methods, such as internal channels, complex curves, or lightweight lattice structures.

High Strength, Functional Metal Parts

DMLS produces fully functional parts with excellent strength and durability, similar to forged or machined metal components. These parts are suitable for both prototypes and end-use applications.

Reduced Lead Times and Cost Efficiency

Since no molds or special tools are required, DMLS can significantly reduce lead times and costs for low- to medium-volume production. It’s also ideal for quickly iterating designs without extra tooling costs.

Common Applications of DMLS

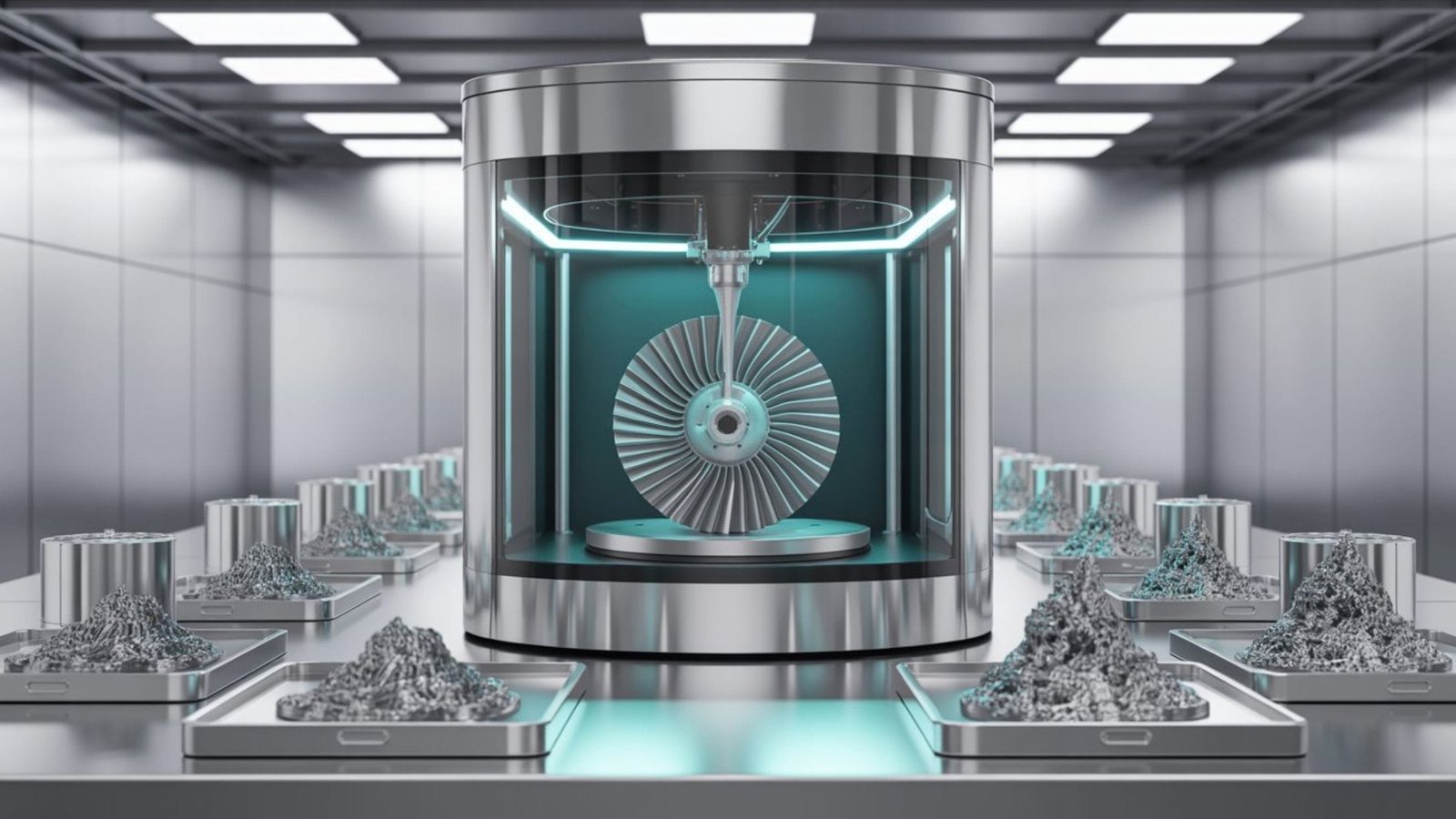

Aerospace and Defense

DMLS is widely used in the aerospace industry to produce lightweight, yet strong, parts such as brackets, housings, and even engine components. It helps reduce weight while maintaining high performance.

Medical Implants and Surgical Tools

In the medical industry, DMLS is used to create custom implants and surgical instruments. Titanium is often used because it’s biocompatible and strong, making it ideal for patient-specific parts like orthopedic implants.

Automotive and Motorsport

Car manufacturers and racing teams utilize DMLS to produce lightweight, high-performance parts, including exhaust components, brackets, and heat exchangers. It allows for rapid prototyping and fast production of custom parts.

When Should You Use DMLS?

Ideal Scenarios for DMLS

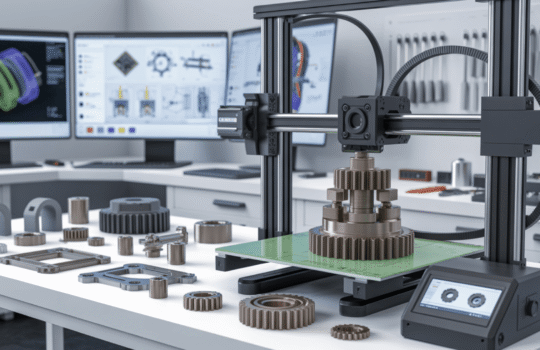

DMLS is ideal for producing complex metal parts in small to medium quantities. It’s a go-to solution for functional prototypes, custom end-use parts, and lightweight designs that are difficult or impossible to produce traditionally.

When DMLS May Not Be the Best Fit

If you need high-volume production of simple parts, or if your project doesn’t require metal, traditional manufacturing or plastic 3D printing may be more cost-effective. DMLS is most valuable when complexity and customization are important.

DMLS vs Other Metal 3D Printing Technologies

It’s easy to confuse DMLS with other metal 3D printing methods. For example, Selective Laser Melting (SLM) is similar but fully melts the powder, while DMLS sinters it. Binder Jetting, on the other hand, uses a binding agent instead of a laser. Compared to these, DMLS offers a good balance of detail, strength, and design flexibility.

Is DMLS Right for Your Project?

Direct Metal Laser Sintering is a game-changer for industries that need strong, precise, and complex metal parts without the delays and costs of traditional manufacturing. If you need functional metal parts quickly, especially for aerospace, medical, or automotive applications, DMLS might be your best option.

At Tesseract, we help businesses select the ideal 3D printing process for their specific needs. Ready to explore DMLS for your project? Get in touch with our experts today!