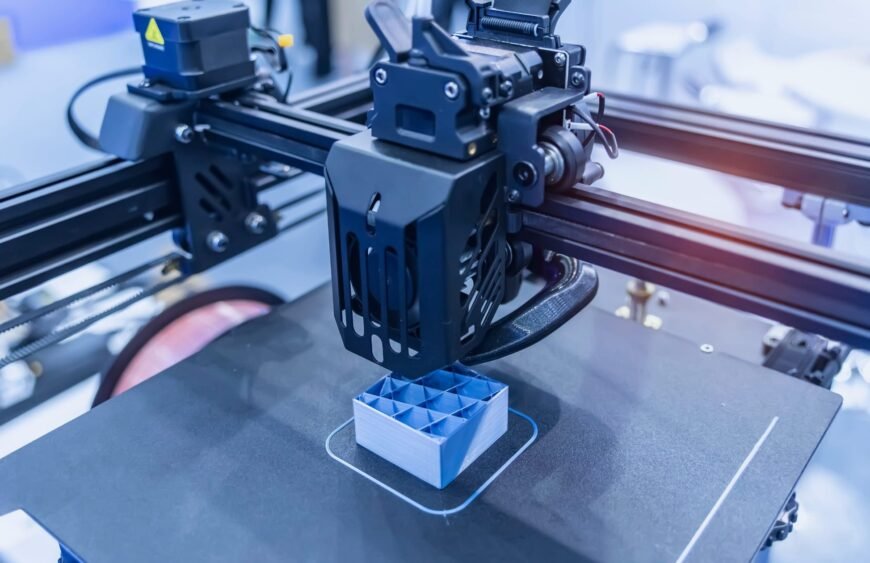

3D printing has steadily moved from prototyping labs into the world of design, and nowhere is its impact clearer than in interior decor. Among the different technologies, SLA (Stereolithography) printing stands out because of its precision, smooth finishes, and ability to handle intricate details. Designers, architects, and homeowners are increasingly using SLA printing to create unique lighting features, custom handles, and artistic decor elements.

But achieving professional-quality results requires more than just hitting “print.” Below are the best practices for using SLA printing in modern interior decor, covering design, material choice, post-processing, and implementation.

Best Practices in Design Preparation

Prioritise Function and Aesthetics Together

One of the strengths of SLA printing is the freedom it gives in design. However, when creating interior pieces, it’s not enough to focus on looks alone. Think about how the object will be used daily. For example, a 3D-printed lamp shade should be not only elegant but also allow for proper heat dissipation and light diffusion. Balancing functionality with visual appeal ensures the piece becomes a lasting addition to the room.

Optimise Wall Thickness & Structural Strength

While SLA can capture extremely fine details, thin walls can become brittle over time, especially in decorative items that might get handled, such as drawer knobs or sculptural accents. A practical approach is to design walls thick enough to withstand regular use without sacrificing elegance. This prevents cracks, chips, or warping down the line.

Plan for Supports and Orientation

How a piece is oriented during printing affects surface quality and post-processing effort. Always plan support placement in areas that are less visible once installed. This minimizes blemishes in prominent areas and reduces the amount of sanding and finishing work later.

Best Practices in Material Selection

Match Resin Type to Application

Not all resins are created equal. Standard resins are great for simple decorative objects, but for pieces that must withstand handling, tough or engineering-grade resins are better. Transparent resins are perfect for lighting fixtures, while flexible resins can be useful for cushioning elements such as chair accessories or soft-touch features. Matching resin to the intended use is key for longevity.

Consider Safety and Longevity

Since interior decor pieces live inside homes, safety is crucial. Fully cured resins are safe, but it’s best practice to ensure prints undergo proper post-curing to eliminate any residual chemicals. Additionally, resins can be prone to yellowing under sunlight. Choosing UV-resistant resins or applying a protective topcoat ensures the piece maintains its appearance over time.

Best Practices in Post-Processing

Sanding and Smoothing for Professional Finish

Raw SLA prints often look impressive, but visible layer lines or small blemishes can detract from their integration into high-end interiors. Gentle sanding, followed by priming, helps achieve a flawless surface. Taking the time to smooth surfaces makes the difference between something that looks “3D printed” and something that looks like a polished design object.

Coatings and Painting

SLA prints take well to finishing treatments. Applying paint, metallic coatings, or even textured finishes allows prints to blend seamlessly with interior styles. For example, a 3D-printed resin handle can be coated to look like brass or bronze, giving a premium touch without the cost of casting metal.

UV Protection and Sealing

For decor placed near windows or under direct light, applying UV-resistant coatings prevents yellowing and extends the lifespan of the print. Sealing with clear coatings also adds a layer of protection against dust and handling, keeping surfaces pristine longer.

Best Practices in Practical Implementation

Modular Printing for Larger Decor Elements

One limitation of SLA printers is build size. Large decor pieces such as wall panels or sculptures may need to be printed in sections. Designing with modularity in mind allows for easy assembly and avoids compromising on scale. Seamless joining techniques, such as hidden interlocks or adhesives, make it possible to achieve a unified final product.

Balancing Cost with Creative Impact

SLA printing delivers premium quality, but it comes at a higher cost than other 3D printing methods. To maximize impact, use SLA printing strategically, reserve it for high-touch or statement pieces like light fixtures, handles, or decorative centerpieces, while relying on other methods for less visible components.

Testing and Prototyping

Before committing to a large print, it’s smart practice to prototype smaller versions. This allows designers to test proportions, finishes, and assembly approaches. A scaled-down prototype saves time and resin while ensuring the full-scale version turns out exactly as intended.

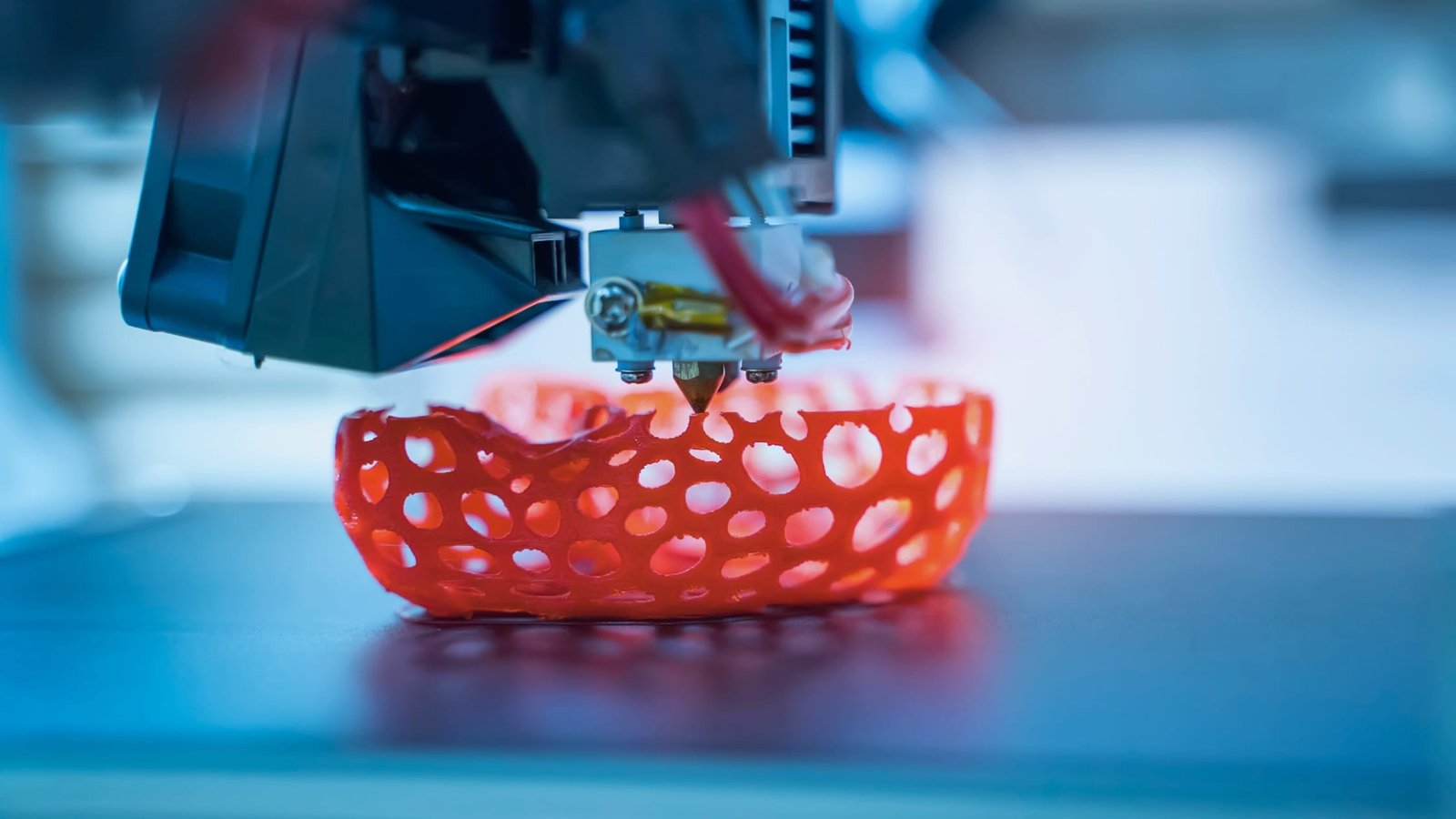

Making SLA Best Practices Work in Interiors

SLA printing opens exciting possibilities for modern interior decor. With its precision and smooth surface finish, it enables the creation of custom pieces that seamlessly combine beauty and function. But success depends on following best practices: thoughtful design preparation, smart resin selection, meticulous finishing, and practical implementation strategies.

By applying these principles, designers and homeowners can unlock the full potential of SLA printing, producing decor that is not just visually stunning, but also durable, safe, and well-suited for everyday living.

If you’re looking to bring a touch of modern innovation into your interiors, SLA printing offers the perfect balance of creativity and craftsmanship when used with best practices in mind.