The toy industry is experiencing a revolution in 2026. 3D printed toys are transforming how children play and learn. These innovative playthings offer endless customization, sustainability, and creativity. Parents and educators are embracing this technology for its unique benefits. In this guide, you’ll discover what 3D printed toys are and learn the complete creation process. Whether you’re a parent, educator, or hobbyist, understanding 3D printed toys opens up a world of possibilities.

What Are 3D Printed Toys?

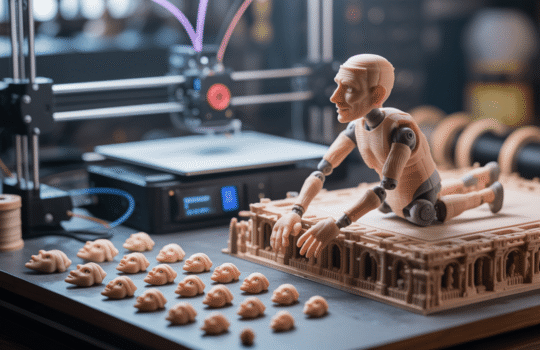

3D printed toys are playthings created layer by layer using additive manufacturing technology. Unlike traditional factory-made toys, these are built from digital designs using 3D printers.

The variety includes action figures, educational puzzles, building blocks, fidget toys, and miniature vehicles. Each toy transforms from a digital file to a physical object within hours.

Common materials include PLA (polylactic acid), ABS plastic, and biodegradable resins. PLA is most popular because it’s non-toxic and eco-friendly.

The biggest advantage is customization. Kids can have toys with their names, favorite colors, or unique designs, options you won’t find in regular stores.

How Are 3D Printed Toys Made?

Creating 3D printed toys involves five simple steps. The process is faster and more flexible than traditional manufacturing.

Step 1: Design Creation

First, you need a digital 3D model. Designers use CAD (Computer-Aided Design) software like Tinkercad, Fusion 360, or Blender. These programs let you create any shape imaginable.

Don’t want to design from scratch? Download pre-made designs from websites like Thingiverse or MyMiniFactory. Thousands of free toy designs are available online.

Step 2: File Preparation

Convert your design into a printer-readable format. The most common formats are STL or OBJ files. Next, use slicing software like Cura or PrusaSlicer. This software divides your model into thin horizontal layers. It also generates instructions for your printer.

Step 3: Printing

Load your chosen material into the 3D printer. The printer heats the plastic filament and deposits it layer by layer. Each layer bonds with the previous one to build the toy from bottom to top. Small toys take 2-4 hours to print. Larger, complex toys can take 8-12 hours. The printer works automatically, so you can walk away during this process.

Step 4: Post-Processing

Remove the finished toy from the printer bed. Take off any support structures used during printing. Sand rough edges to make surfaces smooth. You can paint the toy or add decals for extra personalization.

Step 5: Quality Check

Inspect the toy for any defects or sharp edges. Ensure it meets safety standards, especially for young children. Test moving parts to confirm they work properly. Your 3D printed toy is now ready for play.

Benefits of 3D Printed Toys

3D printed toys offer advantages that traditional toys cannot match.

- Customization: Create toys that reflect a child’s personality. Add names, favorite characters, or special features. Every toy can be unique.

- Sustainability: Reduce plastic waste by printing only what you need. Many materials are biodegradable or recyclable. This makes them better for our planet.

- Cost-Effective: Manufacturing small batches becomes affordable. No need for expensive molds or minimum order quantities. Perfect for small businesses and individuals.

- Educational Value: Children learn STEM concepts through design and creation. They understand engineering, problem-solving, and digital skills. This hands-on learning is invaluable.

- Speed: Go from idea to finished product in hours, not weeks. Rapid prototyping lets you test and improve designs quickly.

- Safety: Choose your own materials and avoid harmful chemicals. You control the entire production process. This ensures toys meet your safety standards.

Popular 3D Printed Toys in 2026

The market for 3D-printed playthings continues to grow. Here are the most popular types:

- Custom action figures and dolls featuring personalized faces and outfits

- Educational puzzles that teach math, science, and spatial reasoning

- Building blocks and construction sets compatible with existing toy systems

- Fidget toys and sensory tools for focus and stress relief

- Replacement parts for broken toys, extending their lifespan

- Miniature vehicles, dinosaurs, and fantasy figurines for collectors and kids alike

FAQs

Q1: Are 3D printed toys safe for children?

A. Yes, when made with food-safe, non-toxic materials like PLA. Always check material certifications before printing. Ensure toys have no small detachable parts for children under three. Supervise young children during play with any toy.

Q2: How long does it take to print a toy?

A. Small toys take 2-4 hours to complete. Medium-sized toys need 4-8 hours. Larger, complex toys can take 8-12 hours or more. Print time depends on size, detail level, and printer settings.

Q3: Can I make 3D printed toys at home?

A. Yes, with a home 3D printer and design files. Entry-level printers cost ₹15,000-₹25,000 in India. You’ll also need filament, which costs ₹800-₹1,500 per kilogram. Free design files are available online.

Q4: What materials are best for 3D printed toys?

A. PLA is the safest and most popular choice. It’s biodegradable, non-toxic, and available in many colors. PETG offers more durability for toys that need strength. Always avoid materials with harmful additives in children’s toys.

Q5: Where can I find designs for 3D printed toys?

A. Thingiverse offers thousands of free designs. MyMiniFactory features curated, high-quality models. Cults3D has both free and premium options. You can also hire designers on Fiverr or create your own using free software.

Conclusion

3D printed toys represent the future of play and learning. They combine creativity, sustainability, and personalization in ways traditional toys cannot. The five-step creation process is accessible to anyone with basic equipment. As 2026 brings more affordable printers and eco-friendly materials, this technology will become mainstream.

Ready to explore 3D printing for your next project? Tesseract offers professional 3D printing solutions for businesses and individuals. Start creating unique, memorable toys that inspire imagination and learning today.