Selective Laser Sintering (SLS) is one of the most powerful additive manufacturing technologies available today. Known for producing functional, end-use parts with excellent mechanical properties, SLS 3D printing is driving innovation across a range of industries.

With its ability to create complex geometries without support structures, SLS 3D printing is becoming a preferred solution in modern product development and low-volume manufacturing. Let’s explore the top industries using SLS 3D printing today and why they’re making the shift.

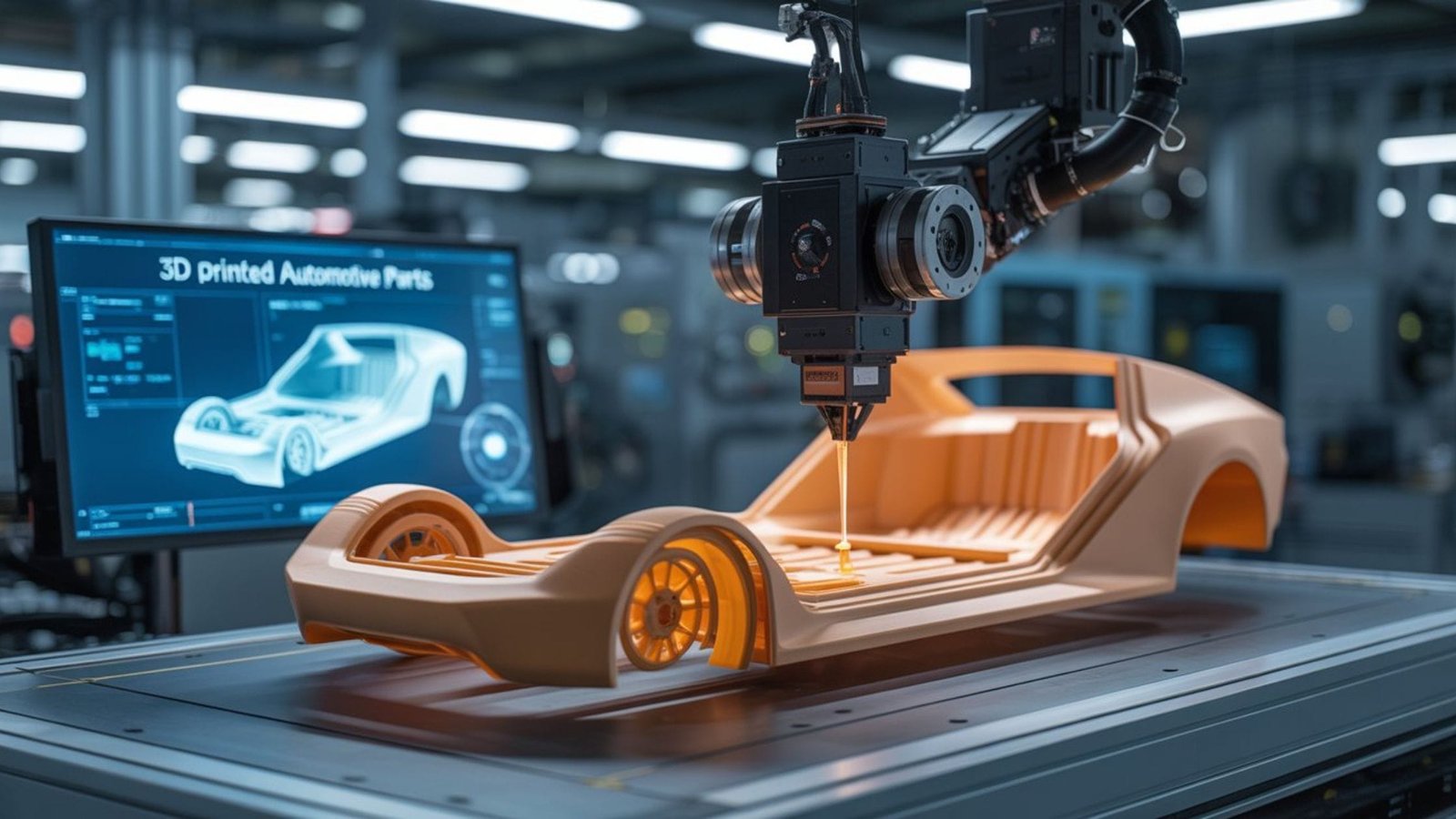

1. 3D Printing in the Automotive Industry

The automotive sector has embraced 3D printing in automotive manufacturing to accelerate product development and reduce costs.

Rapid Prototyping of Functional Components

With SLS, automotive engineers can quickly iterate prototypes like brackets, ducts, and panels, all capable of withstanding heat and stress during road testing.

Lightweight End-Use Parts

SLS is frequently used to create lightweight yet durable components for motorsports, EVs, and custom vehicles, offering optimized part performance without tooling delays.

2. 3D Printing in Aerospace and Defense

3D printing in aerospace demands precision, strength, and rapid iteration, all strengths of the SLS process.

High-Performance Materials for Flight-Ready Parts

SLS materials such as Nylon 12 and carbon-fiber composites are ideal for aerospace parts, including UAVs, aircraft interiors, and satellite components.

Shorter Lead Times in Production

From mission-specific components to low-volume spares, SLS shortens turnaround time for aerospace and defense manufacturers without sacrificing quality.

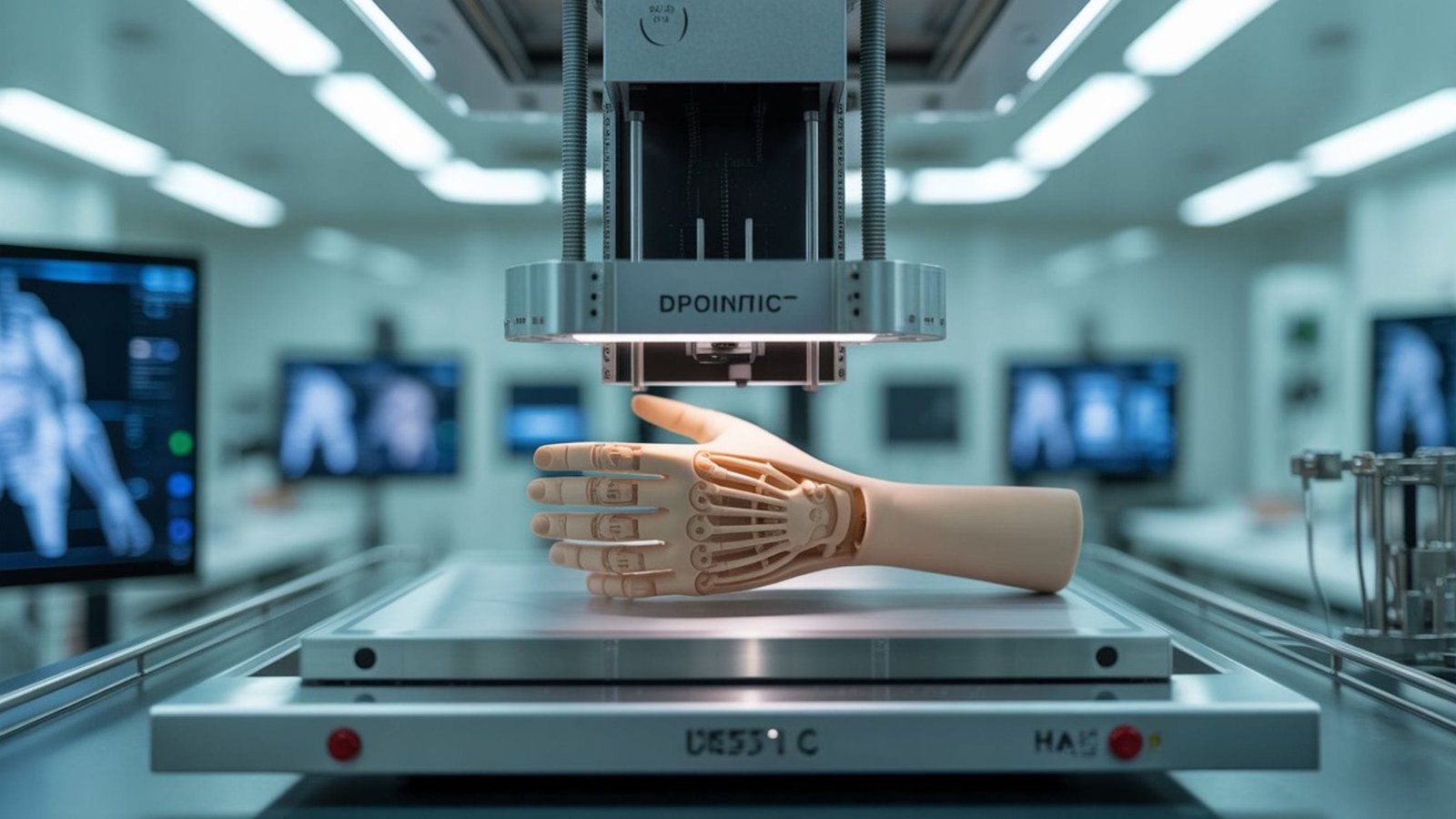

3. 3D Printing in Healthcare and Medical Industry

3D printing in healthcare has evolved far beyond experimentation — it’s now a vital tool for customized patient care.

Custom Medical Devices and Orthotics

SLS enables the production of custom prosthetics, orthopedic supports, and surgical guides that perfectly fit a patient’s anatomy, improving both function and comfort.

Biocompatible and Sterilizable Materials

Medical-grade SLS materials like PA 2200 are sterilizable and skin-safe, making them perfect for wearable medical devices and implants.

4. 3D Printing in Consumer Electronics and Appliances

3D printing in electronics supports fast-paced product development where design and durability matter.

Durable, Aesthetic Prototypes

Electronics brands use SLS to produce functional prototypes for smart devices, wearables, and enclosures, helping them validate both form and fit.

Functional Integration in Small-Batch Production

SLS is ideal for low-volume runs of sensor housings, remote control shells, and IoT device parts, all produced with fine detail and strength.

5. 3D Printing in Industrial Manufacturing

3D printing in manufacturing is reshaping how factories design, test, and replace critical components.

Agile Tooling and Custom Fixtures

SLS is used to produce custom jigs, robotic grippers, and end-of-arm tools tailored to specific production lines, reducing downtime and labor costs.

Bridge Manufacturing and Spare Parts

When traditional tooling is delayed, SLS fills the gap with durable, on-demand production of end-use parts and machine spares.

6. 3D Printing in Footwear and Fashion

3D printing in fashion and footwear is unlocking new creative and performance possibilities.

Customized Fit and Performance

Sports and lifestyle brands use SLS to produce custom insoles, midsoles, and orthotic footwear designed to match individual gait and performance needs.

Design Freedom for Fashion Brands

Fashion designers explore radical new silhouettes, accessories, and garments with the freedom of SLS — no molds or cuts required.

Why These Industries Prefer SLS Over Other 3D Printing Technologies

- No Support Structures: Greater design freedom for complex parts

- Functional Materials: Stronger than FDM, more versatile than SLA

- Scalable Use Cases: Ideal for both functional prototypes and end-use parts

Whether it’s aerospace-grade drone parts or next-gen medical wearables, SLS meets the demand for precision, durability, and speed.

Is SLS 3D Printing Right for Your Industry?

From 3D printing in automotive and aerospace to healthcare and consumer electronics, SLS 3D printing has evolved into a powerful tool for end-to-end product development. It empowers industries to move faster, prototype smarter, and manufacture with fewer constraints.

At Tesseract, we help companies across all sectors leverage SLS 3D printing for innovation and growth. Whether you’re prototyping a breakthrough device or scaling up for low-volume production, our expertise ensures you get there faster, with less risk and more confidence.

Ready to explore SLS 3D printing for your business? Contact us or request a quote to get started.