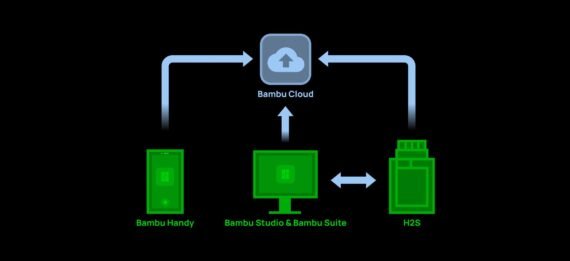

BAMBU LAB H2S FDM 3D PRINTER

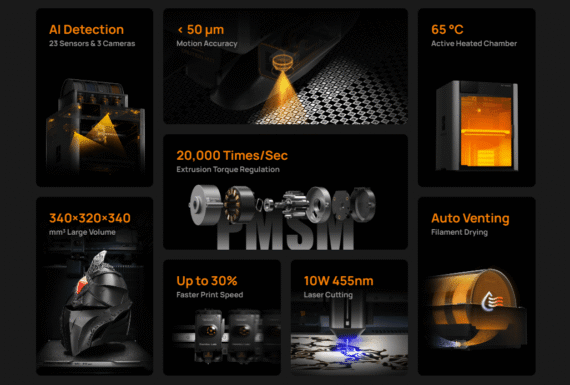

Product Features:

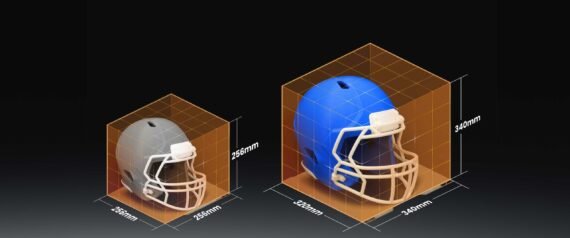

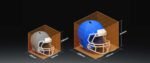

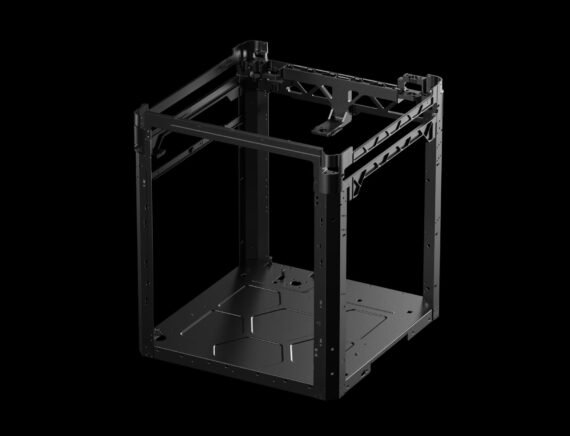

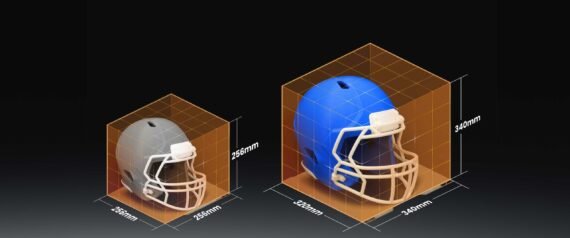

- 340*320*340 mm³ Print Volume

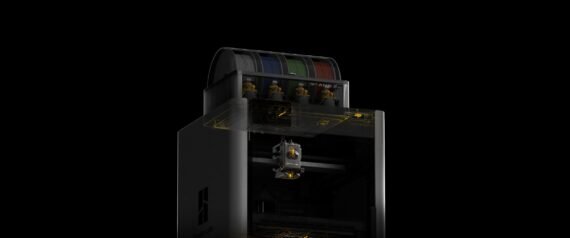

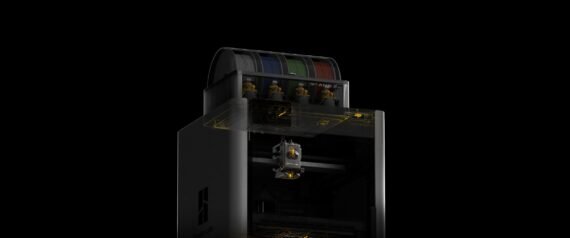

- Multi-color 3D Printing

- Closed-loop Servo Motor Extruder

- Optional 10W Laser and Cutting Module

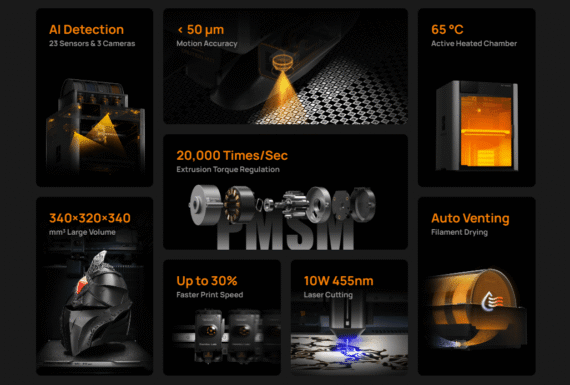

- 5μm Resolution Optical Motion Calibration

- 350°C Nozzle & 65°C Active Chamber Heating

- Full Filament Path AI Detection

- Voltage Range: 100-120 V

Description

Correct Mechanical Deviations

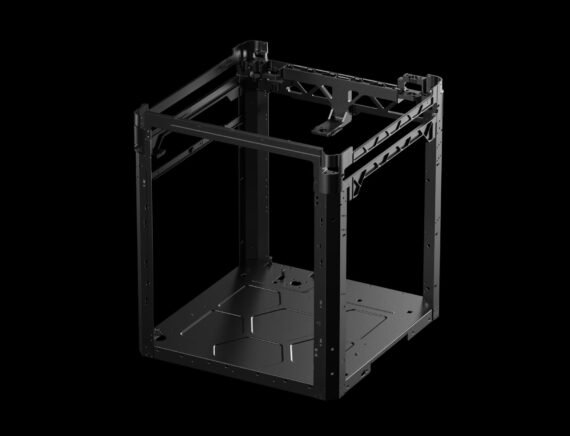

Even the printer comes out of the factory with superb accuracy, mechanical wear and variances over time are inevitable—but now, first time in the industry, there’s a solution.With the Vision Encoder⁽¹⁾, the H2S achieves distance-independent motion accuracy under 50 μm—thinner than a human hair. During calibration, it automatically compensates for mechanical drift, ensuring consistent precision and peak performance over time.

One Print. Perfect Fit.

Ready for Engineering Filaments

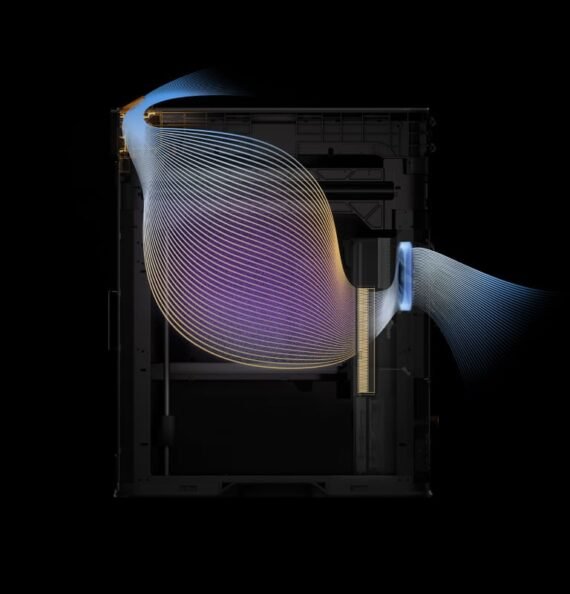

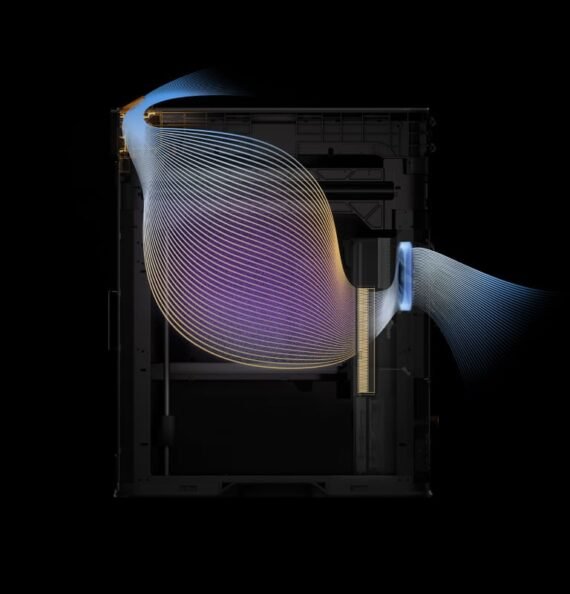

Featuring a 350 °C hotend and a 65 °C actively heated chamber, it supports the entire Bambu filament lineup—from PLA and PETG to PC and PPA. With closed-loop fan control and precise thermal management, the H2S minimizes warping and deformation while improving layer adhesion. Build large, high-performance parts that are as functional as they are strong.

Even Surfaces, Crisp Edges

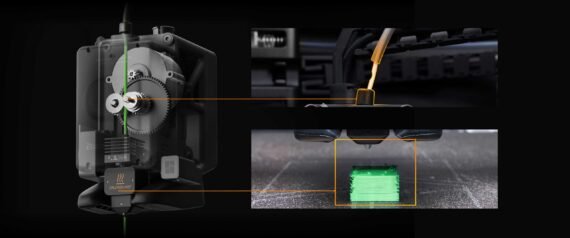

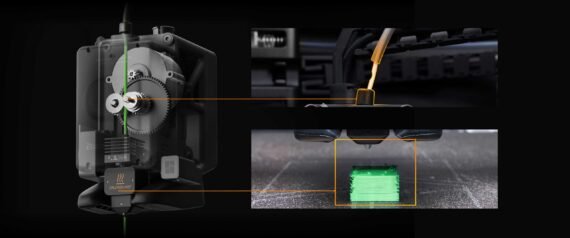

H2S uses both the sensing capability of its servo motor on the extruder and the high-resolution eddy current sensors on the nozzle to precisely control extrusion by measuring nozzle pressure and calibrating PA parameters for each filament, improving surface smoothness and edge sharpness.

Precision in Motion

Active Vibration Compensation neutralizes micro-vibrations and resonance in real time, enabling premium print quality at higher speeds.

Intelligence That’s Got Your Back

20,000 Checks Per Second. Closed-Loop Feedback, Real-Time Control. Bambu Lab’s proprietary PMSM servo system enables 20 kHz resistance and position sampling to dynamically modulate electromagnetic torque vectors. It stabilizes extrusion and actively detects grinding⁽³⁾ or clogs in real time.

23 Sensors + 3 Cameras

Each Potential Risk Has Its Own Detector

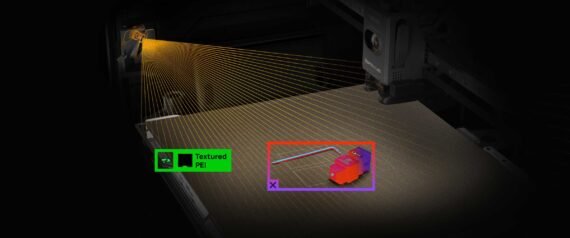

With AI-driven real-time monitoring, the vision system detects clumping, spaghetti and purge chute jamming as they happen, helping prevent failed prints before they start. This same vision system powers advanced features like Live Spatial Alignment, allowing precise laser and cutting calibration, and Vision Encoder technology, which enhances positional accuracy.

Filament-path sensors work in unison to monitor feeding speed and position, detect filament tangles and grinding risks, track filament mileage and spool usage, and ensure tool readiness across the AMS, buffer, cutter, and feeding paths, making sure every tool is in place and every move is under control.

Five NTC temperature sensors are strategically placed across the nozzle, heatbed, and chamber. Paired with integrated airflow sensors, the system actively monitors and adjusts internal temperatures and circulation, maintaining the ideal print environment through real-time feedback control.

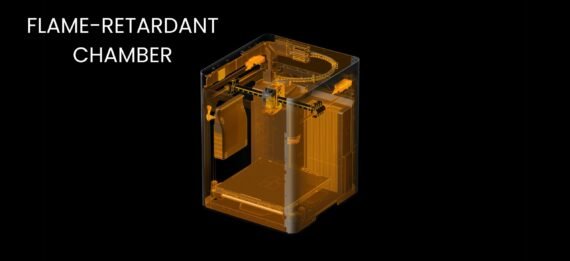

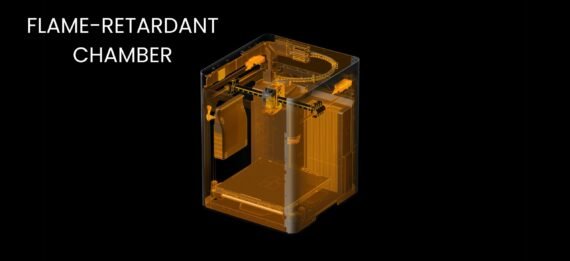

The H2S features five flame sensors, front-door and top-cover sensors, and emergency stop button to form a complete safety system. It detects fire risks, monitors enclosure alignment, and allows instant shutdown when needed—protecting your projects and your workspace at all times.

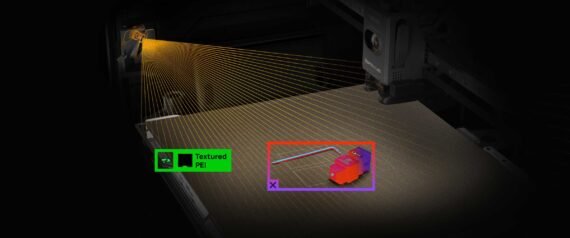

Pre-Flight Checklist by AI

Prior to each operational cycle, the H2S vision system initiates a comprehensive pre-flight checklist: Chamber Integrity Scan – Detects debris across the entire print surface. Hardware Configuration Audit – Instantly identifies build plate properties.

Rating & Review

There are no reviews yet.