Traditional sampling drains budgets for small fashion labels. A single physical prototype costs ₹5,000-₹15,000, and designers need multiple iterations before finalizing designs. Small fashion brands are now turning to 3D printed samples to slash these costs by 60-80%. This technology offers faster turnaround times, design flexibility, and sustainability benefits.

Let’s explore how emerging designers are using this innovation to compete with established brands.

What Are 3D Printed Samples in Fashion?

3D printed samples are digital prototypes converted into physical models using additive manufacturing technology. Fashion labels use them to create jewelry pieces like rings and earrings, buttons, bag hardware, shoe components, and decorative accessories.

Common materials include resin for detailed work, nylon for durability, and TPU for flexible parts. The biggest advantage? Samples are ready in 24-48 hours compared to 2-3 weeks with traditional manufacturing methods.

The Cost Problem Small Fashion Labels Face

Traditional sampling creates significant financial pressure:

- Material costs: ₹2,000-₹5,000 per sample

- Labor charges: ₹3,000-₹8,000 per piece

- Shipping and revisions: Additional ₹2,000-₹5,000

Multiple design iterations multiply these expenses quickly. Small labels often need 5-10 samples before finalizing a design. Manufacturers also impose minimum order quantities that force designers to commit larger budgets upfront. Time delays of 2-4 weeks per iteration slow down market launches and reduce competitiveness.

How 3D Printed Samples Slash Costs

The cost difference is dramatic:

- Traditional sampling: ₹10,000-₹15,000 per piece

- 3D printed samples: ₹2,000-₹5,000 per piece

3D printing eliminates minimum order requirements. Designers order single samples without bulk commitments. Design modifications happen instantly in software without retooling costs. Material waste drops by 90% since printing uses only the necessary material.

International shipping costs disappear when working with local 3D printing services. A Delhi-based accessories brand reported saving ₹3 lakhs in its first year by switching to 3D printed samples.

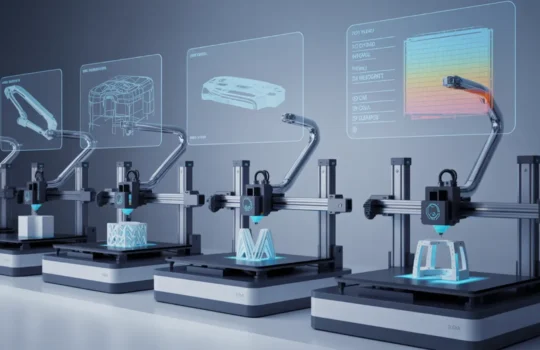

The 3D Printing Process for Fashion Samples

Here’s how small labels create 3D printed samples:

Step 1: The Designer creates a 3D CAD model using software like Blender, Rhino, or Fusion 360.

Step 2: The digital file is uploaded to a 3D printing service like Tesseract.

Step 3: The Designer selects material (resin, nylon, TPU) and finish options.

Step 4: Printing begins—takes 6-24 hours depending on design complexity.

Step 5: Post-processing includes cleaning, curing, and surface finishing.

Step 6: Quality inspection and delivery to the designer.

Total turnaround time is 2-3 days. If changes are needed, designers modify the digital file and reprint quickly without starting from scratch.

Real Benefits Beyond Cost Savings

Faster market entry: Labels launch collections 40% quicker than competitors using traditional methods.

Sustainability advantage: Reduces fabric waste and carbon emissions from shipping samples internationally.

Design innovation: Create complex geometric patterns impossible with traditional manufacturing techniques.

Investor confidence: Physical samples help secure funding and impress potential buyers during presentations.

Market validation: Test customer response before committing to expensive bulk production.

Personalization: Easily customize designs for individual clients without additional setup costs.

FAQs

Q1: Are 3D printed samples as durable as traditional samples?

Yes, for presentation and fitting purposes. Materials like nylon and resin offer good durability. However, final production pieces typically use traditional materials for wear and longevity.

Q2: What fashion items work best with 3D printed samples?

Jewelry, accessories, buttons, bag hardware, shoe components, and decorative elements. Fabrics cannot be 3D printed yet, but accessories work perfectly.

Q3: How much can small labels actually save?

Most labels save 60-80% on sampling costs. With 10 sample iterations, savings reach ₹80,000-₹1,20,000 per collection.

Q4: Do I need special skills to use 3D printed samples?

No. Many 3D printing services like Tesseract offer design assistance. You can also hire freelance 3D designers affordably.

Conclusion

Small fashion labels face tight budgets and fierce competition. 3D printed samples offer a practical solution to reduce sampling costs while accelerating design cycles. The technology saves money, supports sustainability goals, and enables creative freedom. As 3D printing becomes more accessible, forward-thinking designers gain a significant competitive advantage. Start exploring 3D printed samples today to transform your fashion sampling process and protect your bottom line.