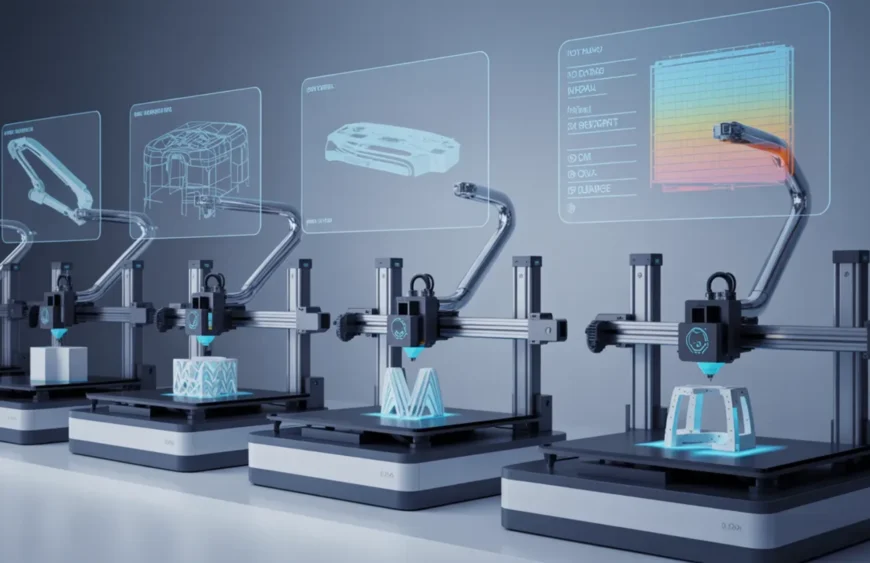

AI in 3D printing is revolutionizing manufacturing by making it faster, smarter, and more efficient. This powerful combination is transforming how we design and create products across industries.

Here’s the simple answer: AI enhances 3D printing through real-time quality control, generative design, predictive maintenance, and automated optimization. By 2026, AI-powered 3D printers reduce errors by 40% and cut production time by 30%. This technology combines machine learning with additive manufacturing to solve traditional 3D printing challenges and creates smarter, self-correcting systems.

Let’s explore how this exciting technology is reshaping the future of manufacturing.

What Is AI in 3D Printing?

AI in 3D printing means using artificial intelligence to make 3D printers smarter and more capable. The technology analyzes printing data in real-time and makes instant adjustments for better results.

Machine learning algorithms continuously optimize the printing process. Computer vision systems detect defects instantly during production. This dramatically reduces the need for human intervention and supervision.

The results speak for themselves. AI-powered 3D printers achieve 95% first-print success rates compared to just 70% with traditional methods. That’s a game-changing improvement for manufacturers.

5 Ways AI Transforms 3D Printing in 2026

1. Real-Time Quality Control

AI cameras monitor every single layer as it prints. These systems detect defects in milliseconds and automatically correct printing parameters before problems escalate.

This technology eliminates waste materials and ensures consistent quality. No more discovering failed prints after hours of work. The AI catches issues immediately and fixes them on the fly.

2. Generative Design

AI creates optimized part designs that humans might never imagine. The technology generates thousands of design options in minutes and selects the best solution.

These AI-generated designs reduce material usage by up to 50% while improving structural strength. It’s like having a genius engineer working 24/7 on optimization. The results are lighter, stronger, and more efficient products.

3. Predictive Maintenance

AI predicts equipment failures before they happen. The system analyzes patterns and schedules maintenance before breakdowns occur.

This approach extends printer lifespan by 25% and minimizes costly downtime. Instead of reactive repairs, manufacturers enjoy proactive maintenance that keeps production running smoothly.

4. Material Optimization

AI suggests the best material combinations for each specific project. The system adapts to different materials automatically and tests material properties virtually.

This capability reduces material costs by 20-30% and ensures optimal performance. Manufacturers no longer waste time and money on material experimentation.

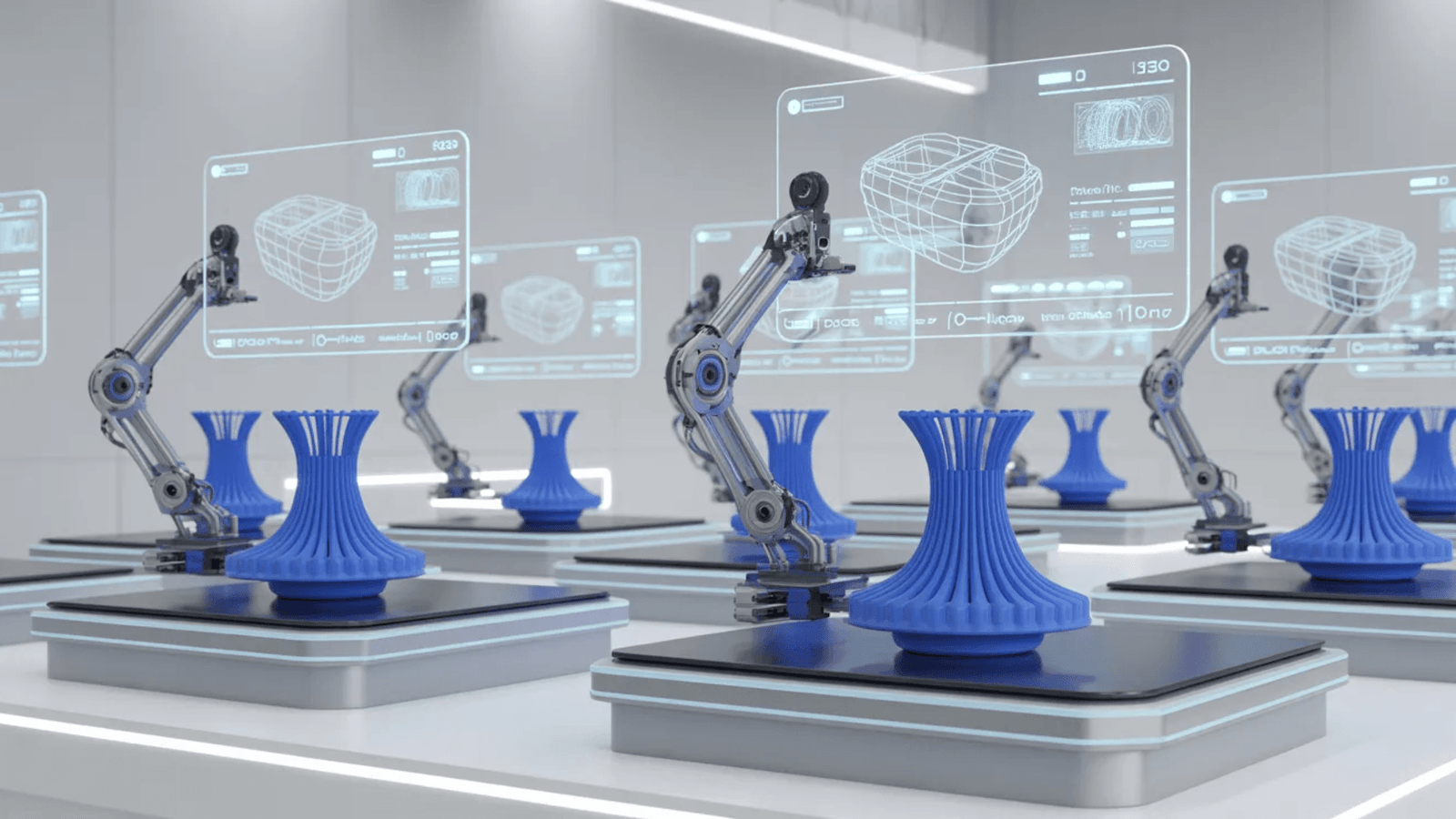

5. Automated Parameter Tuning

AI automatically adjusts speed, temperature, and material flow for perfect results. The system learns from previous prints and optimizes for different geometries.

This eliminates the frustrating trial-and-error process that traditionally plagues 3D printing. Beginners can achieve expert-level results from their first print.

Industries Benefiting from AI-Powered 3D Printing

Healthcare leads the revolution with custom implants and prosthetics tailored to individual patients. AI designs perfect-fit medical devices that improve patient outcomes.

Aerospace companies use AI-powered 3D printing to create lightweight yet incredibly strong components. These parts reduce aircraft weight and improve fuel efficiency.

Automotive manufacturers leverage the technology for rapid prototyping and custom parts production. Development cycles shrink from months to weeks.

Construction firms are printing entire building structures with AI-designed components. This approach reduces construction time by 60% and material waste by 40%.

Fashion brands create personalized products at scale. AI enables mass customization that was previously impossible or economically unfeasible.

Challenges and Solutions

Every new technology faces obstacles. AI-powered 3D printing has three main challenges today.

High initial investment costs concern many businesses. However, cloud-based AI platforms now make this technology accessible without massive upfront expenses. Companies can start small and scale gradually.

The need for skilled operators seems daunting. Modern systems feature user-friendly interfaces that simplify complex operations. The AI handles the technical complexity automatically.

Data security raises valid concerns. Blockchain technology now secures printing data and protects intellectual property. Manufacturers can innovate confidently without security fears.

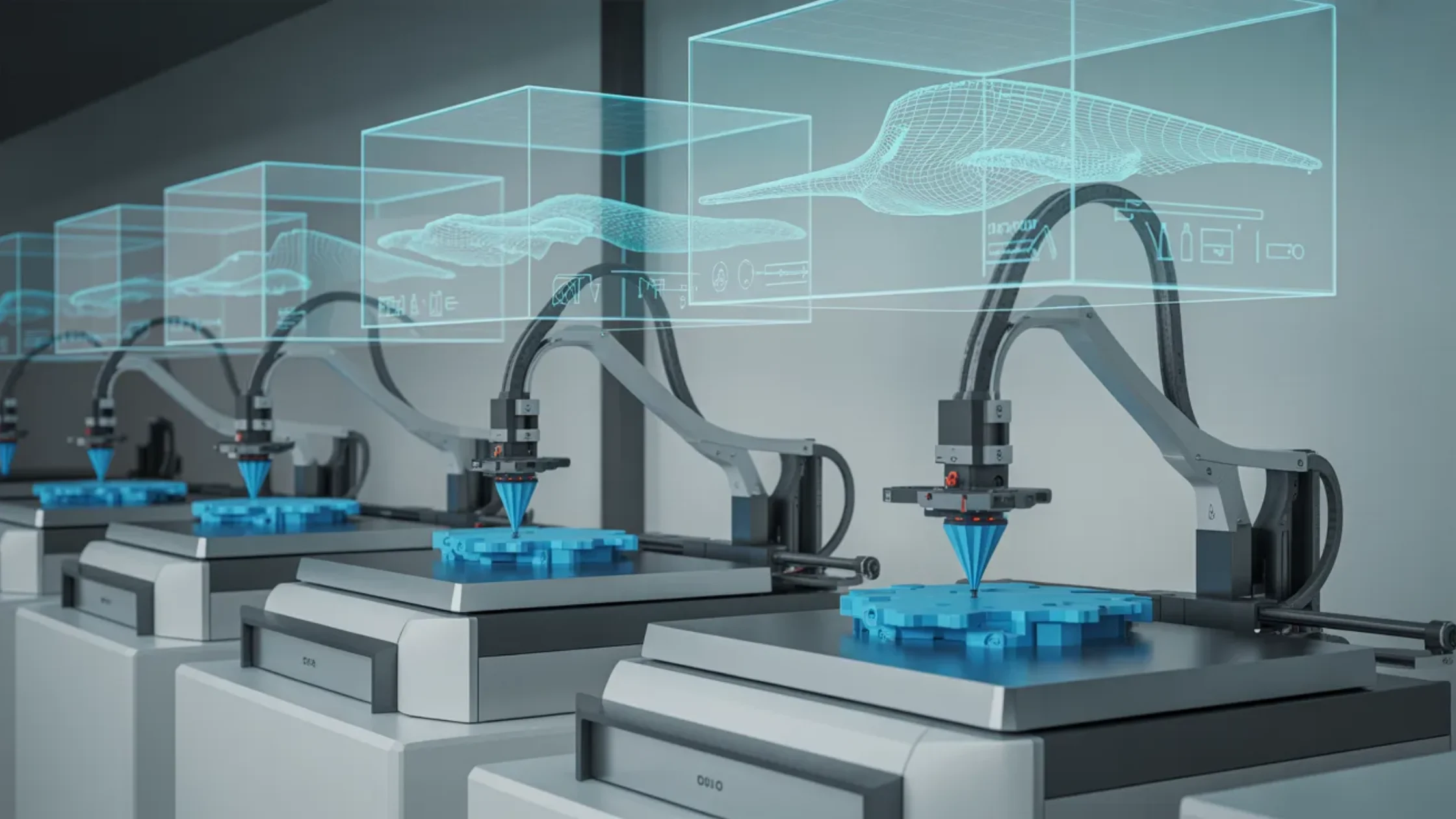

The Future: What’s Next for AI in 3D Printing?

The next five years promise incredible developments. Fully autonomous 3D printing factories will operate with minimal human oversight. AI will design parts directly from simple text descriptions.

Integration with IoT and robotics will create smart manufacturing ecosystems. Mass customization will become the standard, not the exception. Sustainable manufacturing practices will dominate as AI optimizes material usage and reduces waste.

Frequently Asked Questions

1. How does AI improve 3D printing success rates?

AI-powered 3D printers achieve 95% first-print success rates compared to 70% with traditional methods through real-time monitoring and automatic error correction.

2. Is AI-powered 3D printing expensive to implement?

Cloud-based AI platforms make it accessible without massive upfront costs. Companies can start small and scale gradually.

3. Which industries benefit most from AI-powered 3D printing?

Healthcare, aerospace, automotive, construction, and fashion are the leading adopters, each using it for custom parts and rapid production.

4. How much can AI reduce 3D printing errors and production time?

AI reduces errors by 40% and cuts production time by 30%, while also reducing material usage by up to 50%.

5. Do I need specialized skills to operate AI-powered 3D printers?

No. Modern systems have user-friendly interfaces, and the AI handles technical complexity automatically, allowing beginners to achieve expert-level results.

Conclusion

AI in 3D printing is transforming manufacturing from reactive to predictive. By combining machine learning with additive manufacturing, businesses achieve higher quality, lower costs, and faster production.

The technology is no longer experimental. It’s here, proven, and delivering measurable results across industries. Companies adopting AI-powered 3D printing today gain significant competitive advantages.

Ready to upgrade your 3D printing capabilities? Explore Tesseract’s AI-powered 3D printing solutions and join the future of manufacturing.

The fusion of AI and 3D printing isn’t just an upgrade, it’s a complete revolution in how we design, create, and manufacture. The future is intelligent, efficient, and automated. Welcome to the new era of manufacturing.