In an age where personalization, sustainability, and speed-to-market are redefining product design, 3D printing in furniture is no longer a futuristic concept. It is today’s innovation. Designers, manufacturers, and even consumers are tapping into additive manufacturing to reimagine what furniture can look like, how it’s made, and how it functions. At Tesseract, we’re at the forefront of this movement, blending cutting-edge design with advanced 3D printing capabilities to create next-generation furniture solutions.

Revolutionizing Furniture with 3D Printing

Furniture has traditionally been shaped by labor-intensive craftsmanship or the limitations of mass production. But 3D printing, or additive manufacturing, breaks these constraints. It empowers designers to create intricate, made-to-order pieces without the time, waste, or tooling costs associated with traditional fabrication.

Whether it’s a custom ergonomic office chair or a modular shelving system that adapts to a changing space, 3D printing offers control over form, function, and materials like never before.

How 3D Printing Is Transforming Furniture Manufacturing

From Concept to Creation – Faster Design Cycles

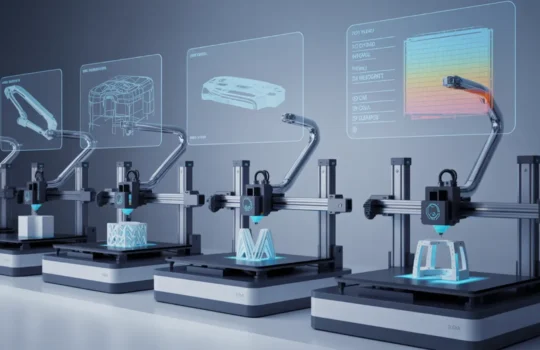

Speed is one of the greatest advantages of 3D printing. With tools like parametric CAD software and generative design platforms, furniture can be prototyped and refined in days instead of weeks. Technologies such as FDM (Fused Deposition Modeling) and SLS (Selective Laser Sintering) allow for functional, life-sized components to be printed quickly, tested, and adjusted with minimal overhead.

Design iterations that once required full workshop setups can now be completed on a desktop or industrial printer, dramatically shortening product development timelines.

Material Innovations in 3D-Printed Furniture

Today’s 3D printed furniture is no longer limited to fragile plastics. We now work with durable carbon-fiber-infused filaments, wood composites, flexible polymers, and bio-resins. Materials like recycled PETG and biodegradable PLA are increasingly used to create sustainable furniture pieces that meet modern environmental standards.

These advances in printable materials mean furniture can be lightweight, sturdy, and even weather-resistant, while using less waste and fewer resources.

Creating Bespoke Furniture with 3D Printing

Consumer-Driven Design and Mass Customization

Customization is no longer a luxury. It is becoming the expectation. With 3D printing, furniture can be tailored to individual body dimensions, lifestyle needs, or aesthetic preferences. At Tesseract, we often use online configurators that let clients personalize everything from seat curvature to table leg height before printing begins.

This kind of mass customization at scale is only feasible through additive manufacturing, allowing businesses to serve niche markets without high production costs.

Complex Geometries Made Simple

3D printing allows the creation of organic, complex shapes that traditional furniture-making techniques cannot handle. Intricate lattice structures, sculptural forms, and parametric textures not only create striking visual appeal but also improve performance by reducing material use while maintaining strength.

This enables ergonomic chairs that contour perfectly to the human body or decorative elements that double as structural supports.

The Rise of Modular Furniture Systems

Snap-Fit and Tool-Free Assemblies

One of the most practical applications of 3D printing in furniture is the design of modular, tool-free systems. Components such as joints, brackets, and connectors can be printed with exact tolerances, allowing parts to snap together securely without screws, nails, or adhesives.

This is ideal for urban living, where flexibility, space-saving design, and easy assembly are essential. Consumers can reconfigure their furniture layouts as their needs change.

Flat-Pack and On-Demand Manufacturing

Just like flat-pack innovations in traditional retail, 3D printing enables a new kind of flat-pack furniture that supports on-demand production. Furniture parts can be printed locally or even by the customer using downloadable files, reducing shipping costs, packaging waste, and overall emissions.

Some furniture brands are already experimenting with downloadable kits, shipping only non-printable elements such as cushions or glass surfaces.

Why 3D Printing Is Ideal for Furniture and Where It Falls Short

Key Benefits

- Customization: Fully tailored pieces that match consumer needs

- Sustainability: Reduced material waste, energy usage, and carbon footprint

- Speed: Fast prototyping and production cycles

- Design Freedom: Creation of complex geometries and unique aesthetics

Current Limitations

While the potential of 3D printed furniture is massive, a few challenges remain:

- Size constraints can limit the production of large parts on smaller printers.

- Surface finish often requires post-processing to achieve a premium look.

- Structural integrity for load-bearing items may still require the support of traditional materials like wood or metal.

Many designers are solving these issues by combining 3D printing with CNC machining, welding, or conventional carpentry in hybrid production workflows.

What’s Next for Additive Manufacturing in Furniture?

Emerging Trends

The future of 3D printed furniture includes smart materials, embedded technology, and AI-optimized designs. Imagine smart desks that adapt to posture changes, or recyclable furniture that can be reprinted into new forms as your space evolves.

Developments in large-format printers, robotic arms, and closed-loop materials are making it easier to 3D print architectural-scale furniture and public installations.

Opportunities for Designers, Makers, and Architects

As digital fabrication becomes more accessible, small design studios and independent makers can compete with large furniture brands. 3D printing supports localized production, enabling cities and communities to manufacture furniture closer to the point of use, with reduced costs and environmental impact.

A New Era of Furniture Design

3D printing is more than a technology. It is a design revolution. From custom-fit furniture to reconfigurable modular systems, 3D printing in furniture is changing how we design, produce, and experience our living and working environments.

At Tesseract, we are excited to lead the charge in bringing next-generation furniture to life through advanced additive manufacturing. Whether you are a designer, architect, or brand ready to explore the potential of 3D printed furniture, the future is already being built—one layer at a time.