Stop-motion animation has evolved from handmade clay figures to precision-engineered characters. Traditional puppet-making is time-consuming and limits creative possibilities. 3D printing in stop-motion has revolutionized how studios create detailed, expressive characters. This technology allows animators to produce complex puppets faster and with greater consistency than ever before.

What Is 3D Printing in Stop-Motion?

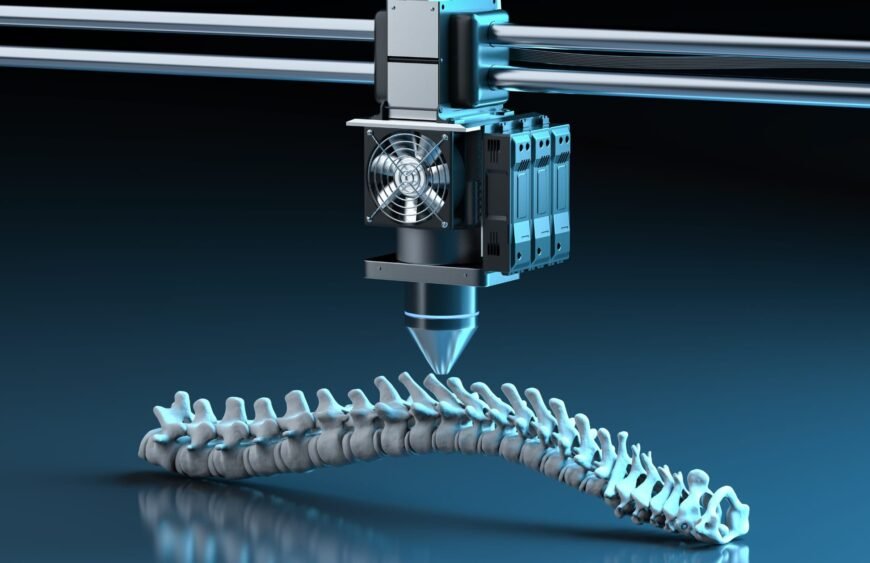

3D printing in stop-motion uses additive manufacturing to create physical puppet parts for frame-by-frame animation. The process flows from digital sculpting to 3D printing, then painting and assembly, and finally filming.

Common Printed Components Include:

- Facial expressions and replacement heads

- Hands in various positions

- Props and set pieces

- Armature components

This approach allows animators to create hundreds of facial expressions and character variations. Major studios like Laika pioneered this technique in films such as Coraline and Kubo and the Two Strings. The result is smoother animation and more nuanced character performances.

The 3D Printing Process for Stop-Motion Characters

Step 1: Digital Sculpting

Artists design characters in software like ZBrush or Blender, creating every detail digitally first. This digital foundation allows for precise modifications and unlimited iterations.

Step 2: Expression Library

Designers create dozens or hundreds of facial variations for different emotions. A single character may need 200+ printed faces for a short film. Each face captures a specific mouth position or emotional state.

Step 3: Printing and Post-Processing

Printing uses resin or polymer materials for smooth surface finish and fine details. Post-processing follows, where technicians remove supports, sand surfaces, and apply paint or texture. Assembly attaches printed parts to metal armatures for movement.

During filming, animators swap faces and parts between frames for seamless motion. This modular approach makes complex performances possible.

Benefits of 3D Printing in Stop-Motion Animation

Speed and Efficiency

Studios can print multiple character variations simultaneously instead of hand-sculpting each one. What took months now takes weeks. This acceleration doesn’t compromise quality—it enhances production capabilities.

Consistency and Precision

Every printed part matches the original design exactly. Traditional sculpting creates slight variations between pieces, while 3D printing maintains perfect uniformity. Detail capture exceeds what human hands can achieve, reproducing fine textures, wrinkles, and micro-expressions impossible to sculpt manually.

Key Advantages Include:

- Easy digital modification and quick reprints

- Reduced labor hours while maintaining high quality

- Creative freedom for complex designs

- Scalability for multiple characters or backup parts

- Cost control through efficient material use

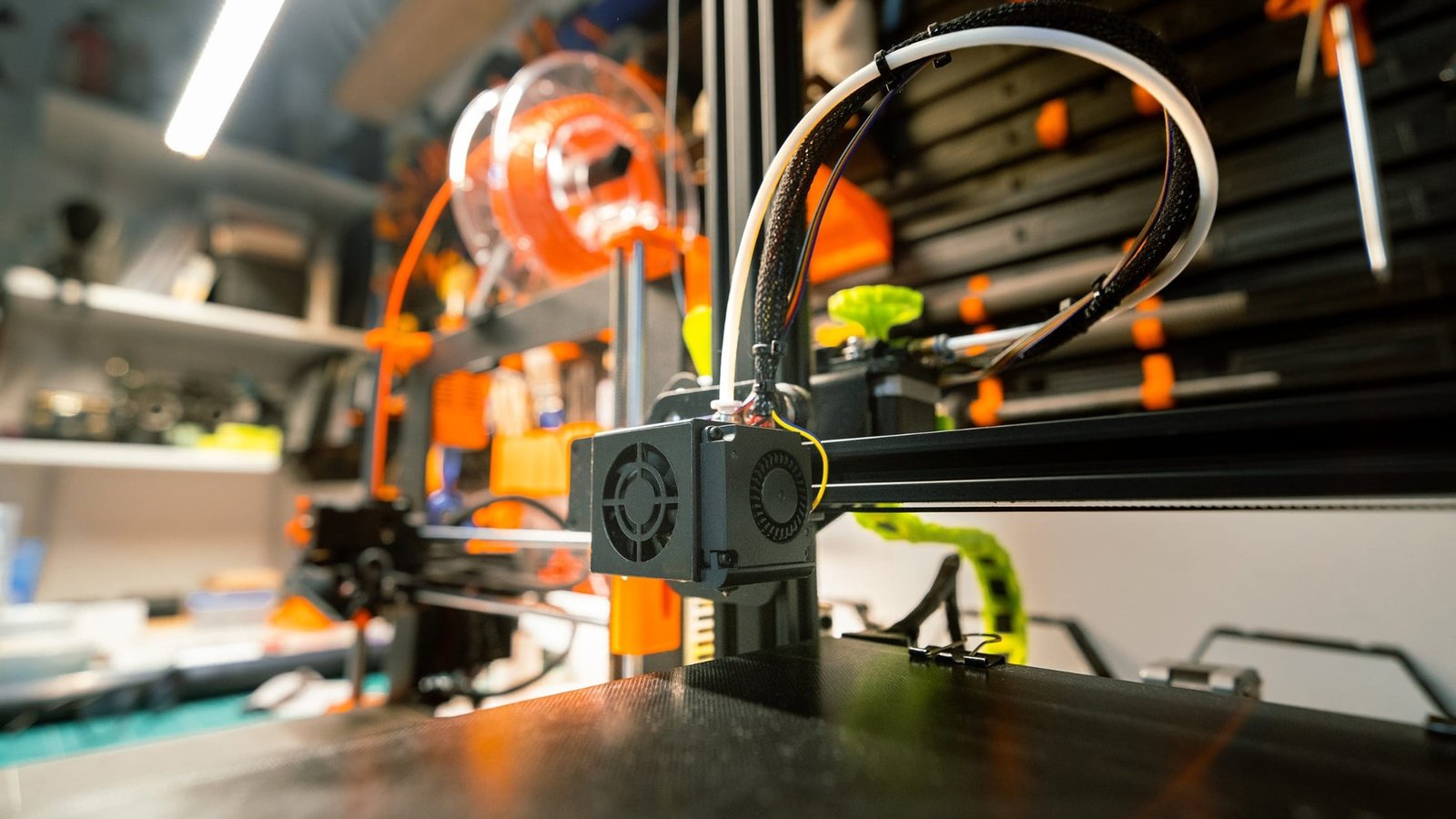

Materials Used in Stop-Motion 3D Printing

Resin (Most Common)

Resin is the most popular material. It provides a smooth finish and captures fine details needed for faces and hands. Most facial expressions use resin printing because of its superior surface quality.

Durable Materials

Nylon and polyamide work well for armature parts and joints that need flexibility. These materials withstand repeated handling during animation. TPU, a flexible filament, creates soft elements like clothing or bendable accessories.

Material Selection Depends On:

- Surface finish requirements

- Durability for repeated handling

- Paint adhesion properties

- Weight considerations for puppet balance

Photopolymer offers color options and translucency for special effects. Some studios use it for eyes or magical elements that require unique visual properties.

How to Select the Right 3D Printing Method

For Detailed Character Parts

SLA and DLP resin printing work best for facial features and detailed parts. These methods are most popular for stop-motion work because they deliver the smoothness and precision animators need. Entry-level resin printers start under ₹40,000, making this technology accessible.

For Props and Sets

FDM printing suits larger props, sets, and structural armatures. It’s less expensive but produces visible layer lines that require more post-processing.

For Professional Studios

Material jetting offers full-color printing without painting. Major studios use this method despite higher costs when they need the highest quality results.

Selection Criteria:

- Detail level required for the project

- Budget constraints and timeline

- Available post-processing capabilities

- Production volume needs

Frequently Asked Questions

What type of 3D printer is best for stop-motion animation?

Resin printers (SLA or DLP) are ideal. They produce smooth surfaces and capture fine facial details. Entry-level models start under ₹40,000.

How many faces does a stop-motion character need?

Simple characters need 50–100 faces, while complex characters in feature films require 200–500 different expressions for various emotions and dialogue.

Can you 3D print an entire stop-motion puppet?

Yes, but most studios print specific parts like heads, hands, and props. The armature is usually metal for durability and precise movement control.

Is 3D printing cost-effective for small studios?

Yes. Reduced labor time and consistent quality offset the initial equipment investment. Entry-level printers make professional results accessible to independent animators.

Conclusion

3D printing in stop-motion has transformed animation from a labor-intensive craft into an efficient digital workflow. Studios now produce characters faster without sacrificing artistic quality. The technology captures details impossible to achieve by hand while maintaining the tactile, physical nature that makes stop-motion special.

As materials improve and printers become more affordable, this technology continues opening new creative possibilities. Whether you’re a professional studio or independent animator, 3D printing in motion helps bring your characters to life with precision and efficiency. The future of stop-motion animation combines traditional artistry with modern manufacturing, creating films that push creative boundaries.