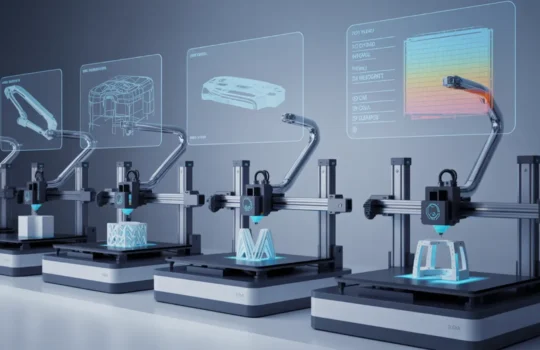

In today’s fast-paced product development landscape, precision is everything. Whether you’re designing intricate prototypes or manufacturing functional micro-components, high-resolution 3D printing offers unmatched accuracy and detail. At Tesseract, we specialize in turning complex digital designs into ultra-precise physical models with exceptional fidelity.

From medical devices to luxury product prototypes, our design-to-manufacturing approach ensures every detail is captured. This blog explores the best techniques and technologies behind high-resolution 3D printing so you can make informed choices when accuracy isn’t just a preference, but a necessity.

What is High-Resolution 3D Printing?

High-resolution 3D printing refers to the ability to produce parts with extremely fine detail, smooth surfaces, and tight tolerances—often at the micron level. Resolution in 3D printing is measured by layer height (Z-axis) and XY resolution, which define the vertical and horizontal accuracy of each print. Lower layer heights (e.g., 25 microns) mean more layers per print, resulting in sharper edges and finer textures. Unlike standard printing, high-resolution methods are crucial for applications in medical modeling, jewelry, miniatures, and aerospace, where every micron counts in function and aesthetics.

Top 3D Printing Technologies for Ultra-Precise Models

Not all 3D printing technologies are built for ultra-fine detail. When precision matters, selecting the right method is critical. Here are the top technologies trusted by professionals for creating high-resolution, highly accurate models:

Stereolithography (SLA)

Stereolithography (SLA) uses a UV laser to cure liquid resin layer by layer, offering an exceptional surface finish and fine detail. With layer heights as low as 25 microns, it’s ideal for dental models, jewelry prototypes, and highly detailed engineering parts. SLA is widely used for presentation-quality prototypes that require visual and dimensional accuracy.

Digital Light Processing (DLP)

Similar to SLA, DLP (Digital Light Processing) cures resin with a digital projector instead of a laser. This allows entire layers to be cured at once, making it faster while still achieving high precision. DLP is perfect for small-batch production and parts with intricate geometries, especially in the medical and electronics sectors.

PolyJet / MultiJet Printing

This inkjet-style process jets photopolymer droplets and cures them with UV light. It supports ultra-thin layers and multiple materials in one print, even simulating rubber or clear parts. PolyJet is often used in industrial design, visual prototyping, and concept models where both detail and multi-material realism are essential.

Each of these technologies brings unique strengths to the table. At Tesseract, we help you choose the right one based on your application, design complexity, and end-use requirements.

Key Techniques to Maximize Print Quality

High-resolution 3D printing isn’t just about the machine—it’s about how you use it. To achieve ultra-precise results, professionals rely on a combination of technical knowledge, software optimization, and post-processing. Here are key techniques that significantly enhance print quality:

Optimal Print Orientation

The angle at which a part is printed affects surface smoothness, feature clarity, and structural strength. Orienting the model to minimize visible layer lines and support marks helps maintain detail while reducing post-processing time.

Advanced Slicing Strategies

Slicing software controls everything from layer height to print speed and exposure time. High-resolution prints often use ultra-fine layers (25–50 microns) and slower print speeds to ensure dimensional accuracy. Adjusting these settings based on geometry is essential for consistent results.

High-Detail Resin Selection

Material choice impacts both detail retention and part durability. Specialized resins—such as those for dental or engineering applications—are formulated for sharp edges, smooth finishes, and minimal shrinkage. At Tesseract, we test and match materials based on your project’s performance and aesthetic needs.

Post-Processing for Surface Perfection

Post-print steps like cleaning, curing, sanding, and coating are critical for achieving that final polished look. UV curing strengthens the print, while careful sanding and finishing elevate the model to display or end-use quality.

By combining these techniques, Tesseract ensures that every high-resolution print not only looks flawless but also performs with precision.

When to Choose High-Resolution 3D Printing

High-resolution 3D printing is the right choice when detail, accuracy, and surface finish are non-negotiable. If your project involves tiny features, tight tolerances, or complex textures, standard printing simply won’t deliver the results you need.

This approach is ideal for:

- Prototypes that mirror final production quality

Impress stakeholders with lifelike models that show every contour and curve. - Miniature or intricate parts

Essential in industries like jewelry, electronics, and medical devices, where even a fraction of a millimeter matters. - Functional components requiring a precise fit

Perfect for assemblies where components must align or interlock flawlessly.

When presentation, performance, or precision are critical, high-resolution printing is the smart investment—and Tesseract ensures it’s done right.

Conclusion

High-resolution 3D printing has redefined what’s possible in product development, enabling unmatched precision, surface quality, and design freedom. Whether you’re crafting detailed prototypes, medical-grade models, or intricate functional components, the right techniques and technologies make all the difference. At Tesseract, we blend expert design insight with cutting-edge 3D printing capabilities to bring your most complex ideas to life.