Injection Moulding

Unlocking Scalability

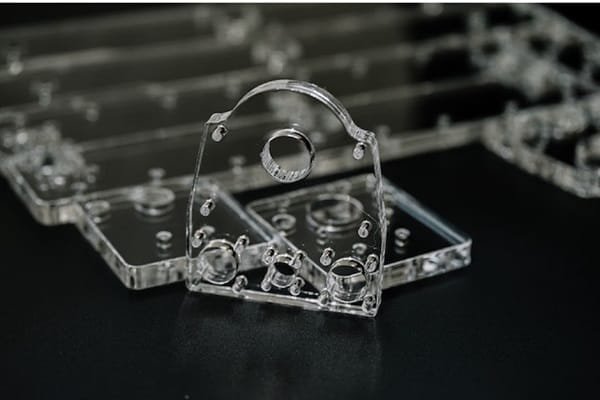

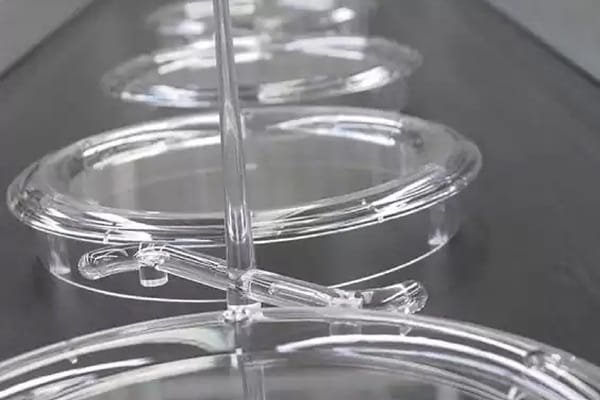

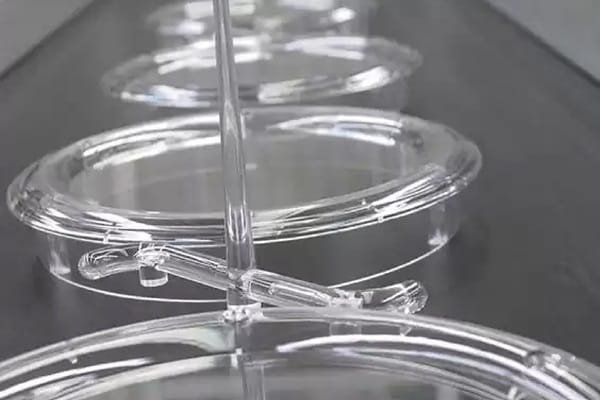

Injection moulding is a versatile manufacturing process used to create parts by injecting molten material into moulds. This method can be employed with a wide range of materials, with thermoplastics and thermosetting polymers being the most common. Designing plastic parts involves considering various factors, including functionality, structural integrity, and the moulding process itself. Following fundamental principles of injection-moulded part design leads to parts that are easier to produce, assemble, and offer enhanced durability. Injection moulding is the preferred method for manufacturing plastic components in large quantities.

USP

High Volume Production

High Tolerance Precision

Repeatability

Wide Material Selection

Cost Effective

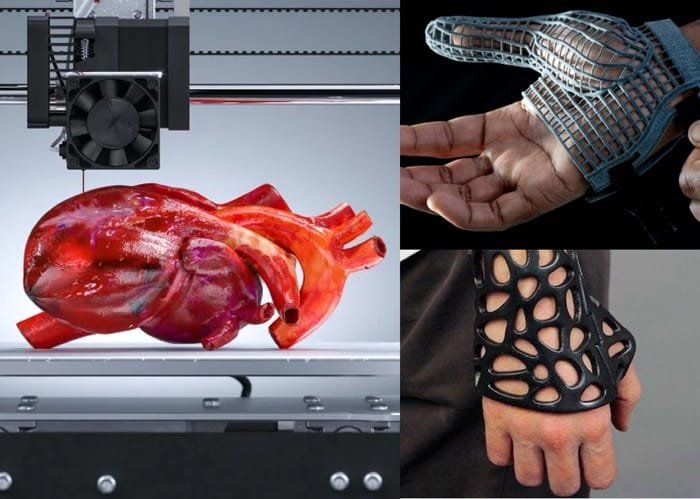

Biocompatibility Certifications

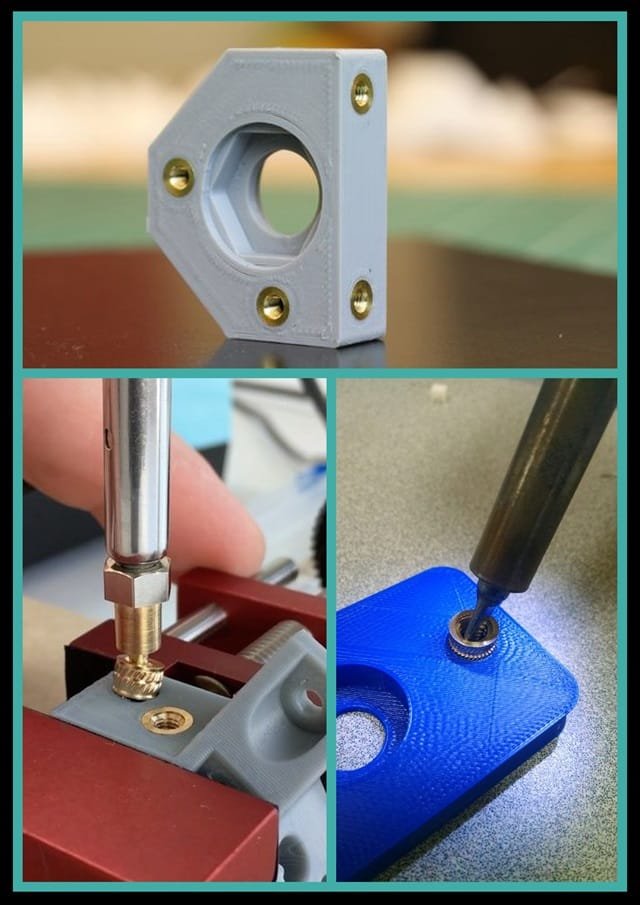

Our Post Processing Offerings

Our Material Offerings

Industries

Precision Injection Moulding Services with Tesseract

At Tesseract, we deliver world-class injection moulding solutions that transform your product concepts into high-quality plastic components. As a leading plastic injection moulding company, we combine advanced manufacturing technology with deep industry expertise to provide exceptional results for businesses across diverse sectors.

Why Choose Tesseract’s Injection Moulding Service?

Injection moulding is one of the most efficient and cost-effective manufacturing processes for producing plastic parts at scale. Whether you need prototypes, low-volume production, or high-volume manufacturing runs, our plastic moulding service is designed to meet your exact specifications with unmatched precision and reliability.

Our Capabilities

DIVERSE MATERIAL SELECTION

Our injection moulding service works with a comprehensive range of thermoplastic materials, including Polypropylene (PP), ABS, Polyethylene (HDPE/LDPE), Polycarbonate (PC), Nylon (PA), and TPE/TPU for flexible applications.

HIGH-PRECISION MANUFACTURING

We utilize state-of-the-art injection moulding machines capable of producing parts with tight tolerances and complex geometries. Our advanced equipment ensures consistent quality across every production run.

CUSTOM MOULD DESIGN

Our engineering team specializes in custom mould design and optimization, ensuring cost efficiency, superior part quality, and long-term durability for high-volume production.

FAST TURNAROUND TIME

With optimized processes and experienced technicians, we deliver fast turnaround times from prototype to production, accelerating your time-to-market.

SUPERIOR QUALITY ASSURANCE

As a certified plastic injection moulding company, we maintain rigorous quality control with first article inspection, statistical process control, and advanced metrology for dimensional accuracy.

Industries We Serve

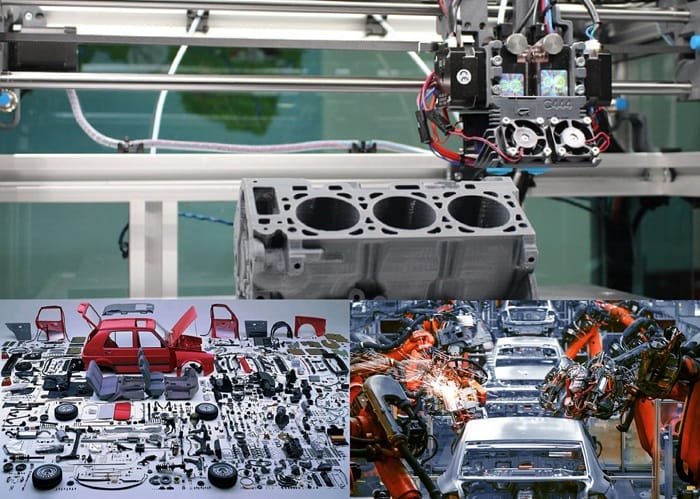

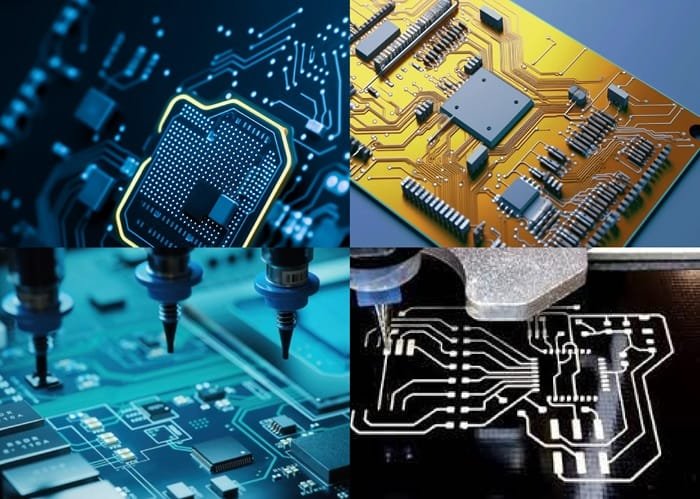

Our plastic moulding service supports automotive, medical devices, consumer electronics, packaging, industrial components, and consumer products.

Contact Tesseract today to discuss your injection moulding project and experience precision manufacturing that exceeds expectations.

FAQ

Injection moulding is a manufacturing process that injects molten material (typically thermoplastics or thermosetting polymers) into custom moulds to create high-quality plastic parts. It’s the preferred method for producing plastic components in large quantities with consistent quality.

We work with comprehensive thermoplastic materials including Polypropylene (PP), ABS, Polyethylene (HDPE/LDPE), Polycarbonate (PC), Nylon (PA), and TPE/TPU for flexible applications, offering diverse options for various functional requirements.

Automotive, medical devices, consumer electronics, packaging, industrial components, and consumer products industries rely on injection moulding for scalable, cost-effective manufacturing of plastic parts with tight tolerances.

Yes, our injection moulding service accommodates prototypes, low-volume production runs, and high-volume manufacturing, offering flexibility from initial concept validation to full-scale mass production with optimized cost efficiency.

Injection moulding offers high-precision manufacturing with tight tolerances, cost-effectiveness at scale, fast turnaround times, the ability to produce complex geometries, consistent quality across production runs, and superior durability for long-term applications.