Vacuum Casting

Unlocking Creation

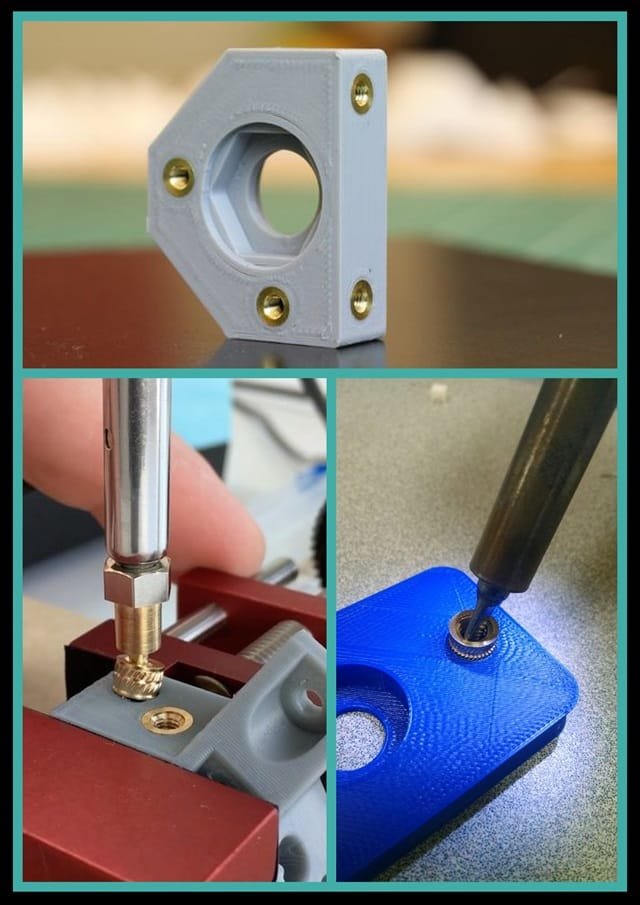

Vacuum Casting is a versatile manufacturing technique designed to produce functional parts in limited volumes. This process leverages two-component polyurethane and silicone moulds to create high-quality plastic parts with finishes akin to those achieved through injection moulding. The quality of the master model, typically crafted via SLA, is pivotal in maintaining excellence throughout production.

USP

Highly Detailed Parts

Material Variety

Swift Turnaround

Low Volume Production

Our Post Processing Offerings

Our Material Offerings

Industries

Why Choose Tesseract for Vacuum Casting?

Vacuum casting is a game-changing process that brings your concepts to life with unmatched accuracy, flexibility, and cost-efficiency. At Tesseract, we take this advanced vacuum casting service to the next level, offering unparalleled expertise and state-of-the-art capabilities. Whether you’re prototyping, creating low-volume production runs, or need high-quality replicas, our resin casting solutions deliver results that exceed expectations.

Why Choose Tesseract’s Vacuum Casting Service?

Tesseract stands out as a leader in the 3D printing and design industry, combining cutting-edge technology with deep industry expertise. Here’s why our vacuum mold casting services are the right choice for your project:

EXPERTISE IN VACUUM CASTING

With over a decade of experience in 3D printing and manufacturing, our team brings a wealth of knowledge and skill to every silicone moulding project. From complex geometries to intricate detailing, we ensure precision and excellence in every vacuum cast part.

PRECISION RESIN CASTING

Vacuum casting requires exacting standards, and Tesseract’s meticulous processes guarantee superior accuracy in every piece. Our advanced tooling and quality control systems ensure flawless replicas every time through our vacuum mold casting process.

INNOVATION & TECHNOLOGY

At Tesseract, we push the boundaries of what’s possible in resin casting. By combining traditional silicone moulding methods with modern 3D printing technology, we offer faster turnaround times and enhanced design capabilities for rapid prototyping.

EXTENSIVE MATERIAL VARIETY

We provide an extensive range of polyurethane resins for vacuum casting, including flexible, rigid, transparent, and colored options. This versatility ensures that your product’s functional and aesthetic requirements are fully met through our resin casting service.

LOW VOLUME PRODUCTION EXCELLENCE

Vacuum casting is ideal for low-volume production, and Tesseract specializes in delivering high-quality parts without the high costs associated with traditional manufacturing methods. Perfect for functional prototypes, pre-production testing, small batch production, and limited-edition runs.

Applications of Vacuum Casting

Our vacuum casting service is perfect for:

- Rapid prototyping for product development

- Pre-production testing and validation

- Master model replication

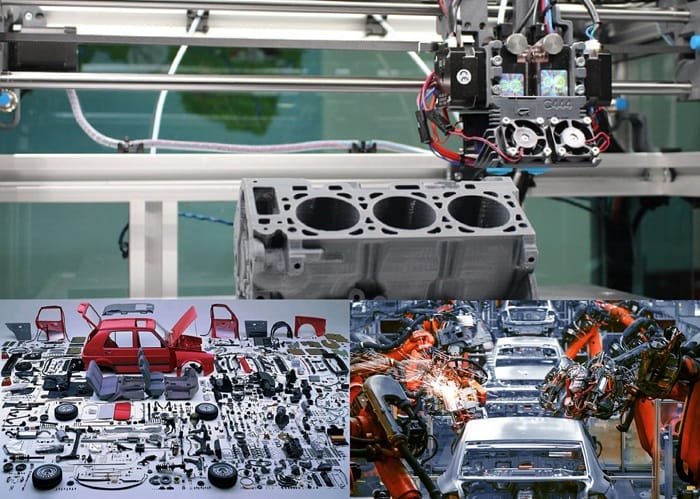

- Automotive prototype parts

- Consumer product prototypes

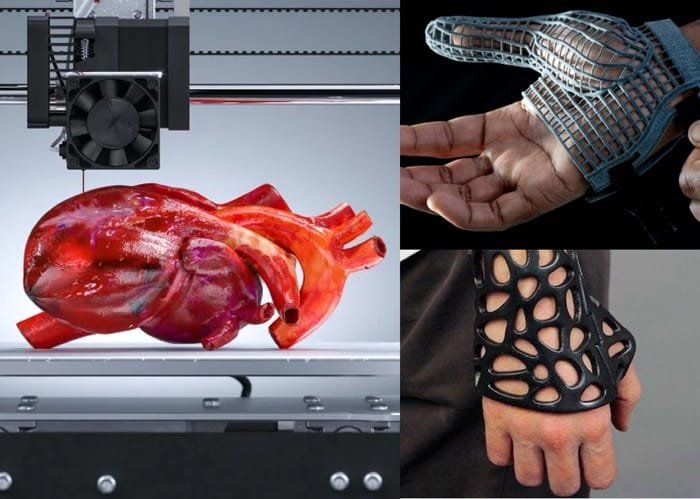

- Medical device prototypes

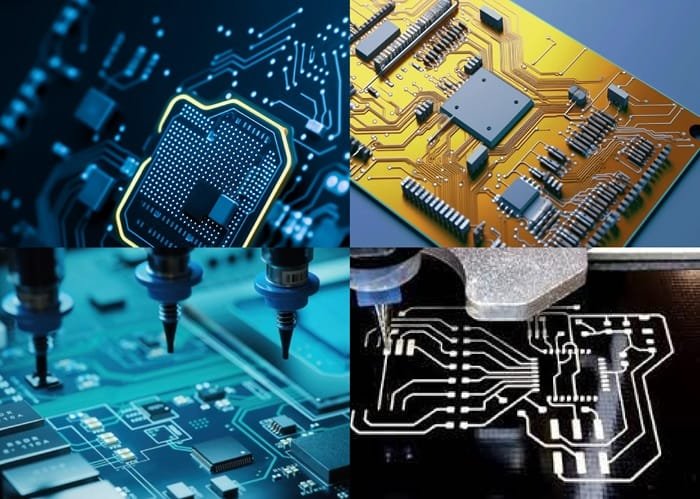

- Custom enclosures and housings

Transforming Your Vision into Reality

Tesseract’s vacuum mold casting services are designed to bring your designs to life with speed, accuracy, and cost-effectiveness. Whether you’re developing prototypes or crafting finished products, our expertise in silicone moulding and commitment to innovation ensure exceptional results.

Partner with Tesseract Today

At Tesseract, we’re not just creating parts; we’re helping you build your future. Our vacuum casting and resin casting services deliver the precision and quality you need to turn your ideas into a tangible reality. Reach out to us today and discover how Tesseract can elevate your project to the next level.

FAQ

Vacuum casting uses silicone molds and two-component polyurethane resins to produce high-quality plastic parts with injection-molding-like finishes. A master model (typically SLA printed) is used to create the silicone mold, then resin is cast under vacuum to eliminate air bubbles and ensure precision.

We offer an extensive range of polyurethane resins, including flexible, rigid, transparent, and colored options. This variety allows us to match your product’s specific functional and aesthetic requirements for any application.

Vacuum casting is perfect for low-volume production, typically ranging from 1 to 50 parts per mold. It’s cost-effective for functional prototypes, pre-production testing, small batch production, and limited-edition runs without the high tooling costs of injection molding.

Vacuum casting serves multiple industries, including automotive (prototype parts), medical (device prototypes), consumer products, and electronics (custom enclosures). It’s ideal for rapid prototyping, product development, pre-production validation, and master model replication.

Turnaround time depends on part complexity and quantity, but typically ranges from 5-10 days. This includes mold creation from your master model and casting the required number of parts, making it significantly faster than traditional manufacturing methods.