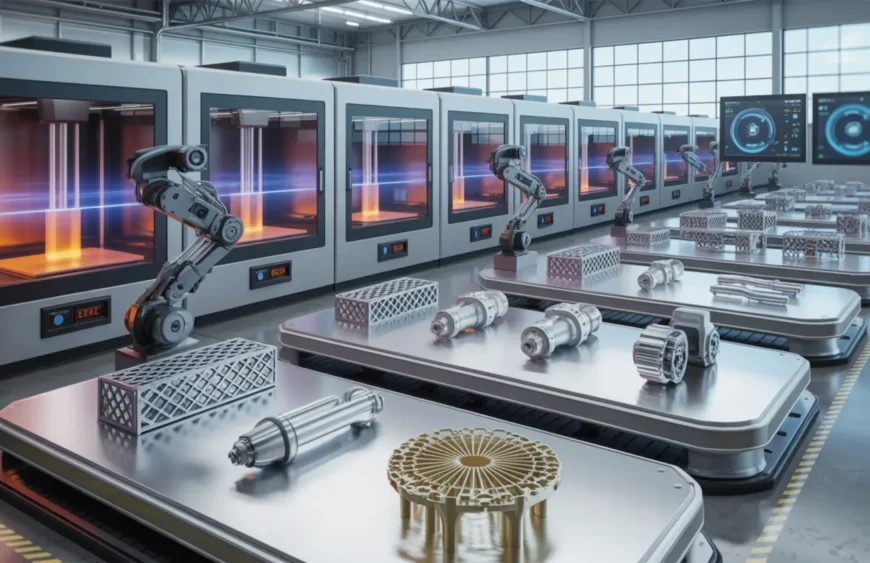

3D printing is no longer just for prototypes. In 2026, manufacturers use 3D printing for full-scale production. Why? Because it’s faster, cheaper, and more flexible than traditional manufacturing.

For years, 3D printing helped designers test ideas. Now, it’s creating finished products. From medical implants to car parts, businesses are replacing traditional production lines with 3D printers. This shift is changing how we make things.

In this guide, you’ll learn why 3D printing became production-ready and how it can benefit your business.

What is Production-Scale 3D Printing?

Production-scale 3D printing means using additive manufacturing to create end-use products, not just prototypes.

The key difference: Prototyping tests designs. Production makes products that customers actually buy and use.

Today, companies like Adidas print thousands of shoe midsoles daily. BMW produces custom car parts on demand. Medical companies create patient-specific implants. The global 3D printing market reached $24 billion in 2025 and continues growing at 23% annually.

This isn’t experimental anymore. It’s mainstream manufacturing.

5 Reasons 3D Printing is Production-Ready

1. Faster Manufacturing Speed

Modern industrial 3D printers produce parts in hours, not weeks.

There’s no tooling setup. No molds to create. You go straight from the design file to the finished product. Carbon’s DLS printers can produce 10,000 parts per day. HP’s Multi Jet Fusion systems run continuously with minimal supervision.

Result: Products reach market 60-90% faster than traditional methods.

2. Lower Production Costs

3D printing eliminates expensive tooling costs that can run $50,000-$500,000 per product.

You only use the material you need. Traditional manufacturing cuts away 90% of material as waste. 3D printing adds material layer by layer, wasting almost nothing.

Example: A small production run of 1,000 custom parts costs 40-60% less with 3D printing versus injection molding.

3. Mass Customization

Every product can be unique without increasing costs.

Nike creates custom-fit insoles for athletes. Hearing aid manufacturers make every device unique to each ear. Jewelry designers offer personalized designs at scale.

Traditional manufacturing requires identical products for efficiency. 3D printing makes customization the default, not an expensive exception.

4. Stronger Materials

Today’s production materials rival traditional manufacturing.

Carbon fiber composites match aluminum strength at half the weight. PEEK plastics withstand 300°C temperatures. Metal 3D printing uses titanium and stainless steel for aerospace-grade parts.

GE Aviation prints fuel nozzles that are 25% lighter and five times stronger than traditionally manufactured versions.

5. On-Demand Manufacturing

Print products where and when you need them.

Spare parts ship as digital files, then print locally. This eliminates warehousing costs and reduces delivery time from weeks to hours.

Case study: Volkswagen keeps digital inventories of classic car parts. When needed, they print them on demand instead of storing thousands of parts for decades.

Industries Leading 3D Printing Production

- Healthcare: Custom dental aligners, prosthetics, surgical guides, and titanium implants

- Aerospace: Airbus and Boeing print 30,000+ parts per aircraft, saving weight and fuel

- Automotive: BMW prints 1 million parts annually for production vehicles

- Consumer Goods: Adidas produced 100,000+ 3D-printed shoes in 2025

These industries proved that 3D printing works for real production, not just testing.

What This Means for Your Business

Start evaluating 3D printing now. You don’t need to replace your entire production line immediately.

Begin with low-volume or highly customized products. Test a single product line. Compare costs with current manufacturing methods.

Many businesses partner with 3D printing service bureaus before investing in equipment. This lets you test production viability without capital investment.

The competitive advantage: Companies using 3D printing respond to market changes faster and offer more customization than competitors.

FAQs

Q: Is 3D printing cost-effective for mass production?

Yes, 3D printing is cost-effective for production runs up to 50,000 units, especially for complex or customized parts. Beyond that volume, traditional manufacturing may still be cheaper for simple, identical items.

Q: What materials can be used for production 3D printing?

Production-grade materials include nylon, PEEK, carbon fiber composites, titanium, aluminum alloys, and engineering-grade resins. These materials meet or exceed traditional manufacturing standards.

Q: How fast can 3D printers produce parts?

Modern industrial 3D printers produce 100-10,000+ parts per day, depending on size and complexity. Print times range from minutes for small items to several hours for large components.

Q: Which companies use 3D printing for production?

Adidas, BMW, GE Aviation, Siemens, Volkswagen, and thousands of smaller manufacturers use 3D printing for end-use production parts daily.

Conclusion

In 2026, 3D printing offers manufacturers a faster, more flexible production solution.

The technology matured. Materials improved. Costs decreased. What seemed impossible five years ago is now standard practice across industries.

The question isn’t whether 3D printing will replace traditional manufacturing. The question is: which parts of your production benefit most from this technology?

Start exploring 3D printing for your production needs today. Your competitors already are.