The global 3D printing market is booming, and industrial companies are leading the charge. More businesses now use 3D printing product design to create better products faster and cheaper. This technology has transformed how companies develop everything from airplane parts to medical devices.

In this blog, you’ll discover the top ways industries use 3D printing and why it’s becoming essential for modern product design.

What Is 3D Printing Product Design?

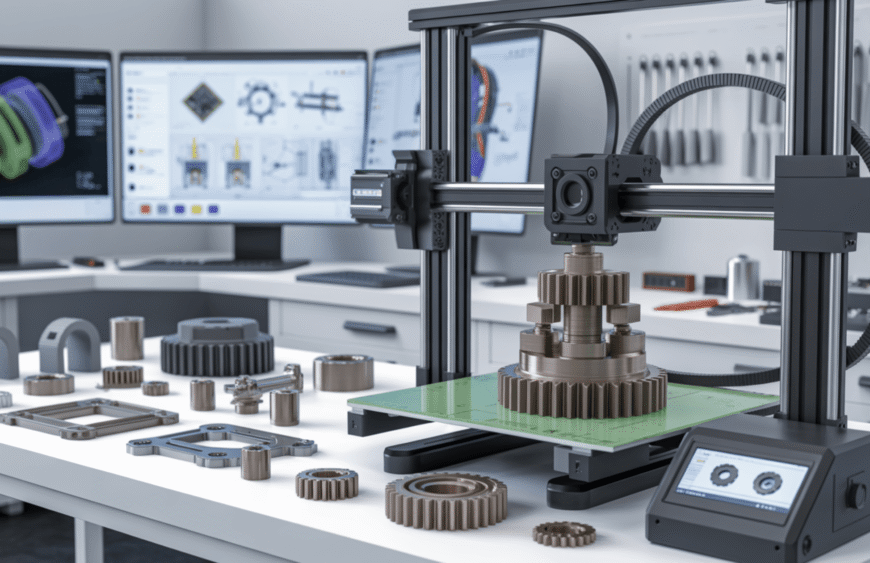

3D printing product design is the process of creating physical objects layer by layer from digital models. Unlike traditional manufacturing that cuts or molds materials, 3D printing adds material only where needed. Companies use it for two main purposes: prototyping new designs and producing final products. Common technologies include FDM for plastics, SLA for detailed resin parts, and SLS for durable industrial components.

Top 5 Ways Companies Use 3D Printing Product Design

1. Rapid Prototyping

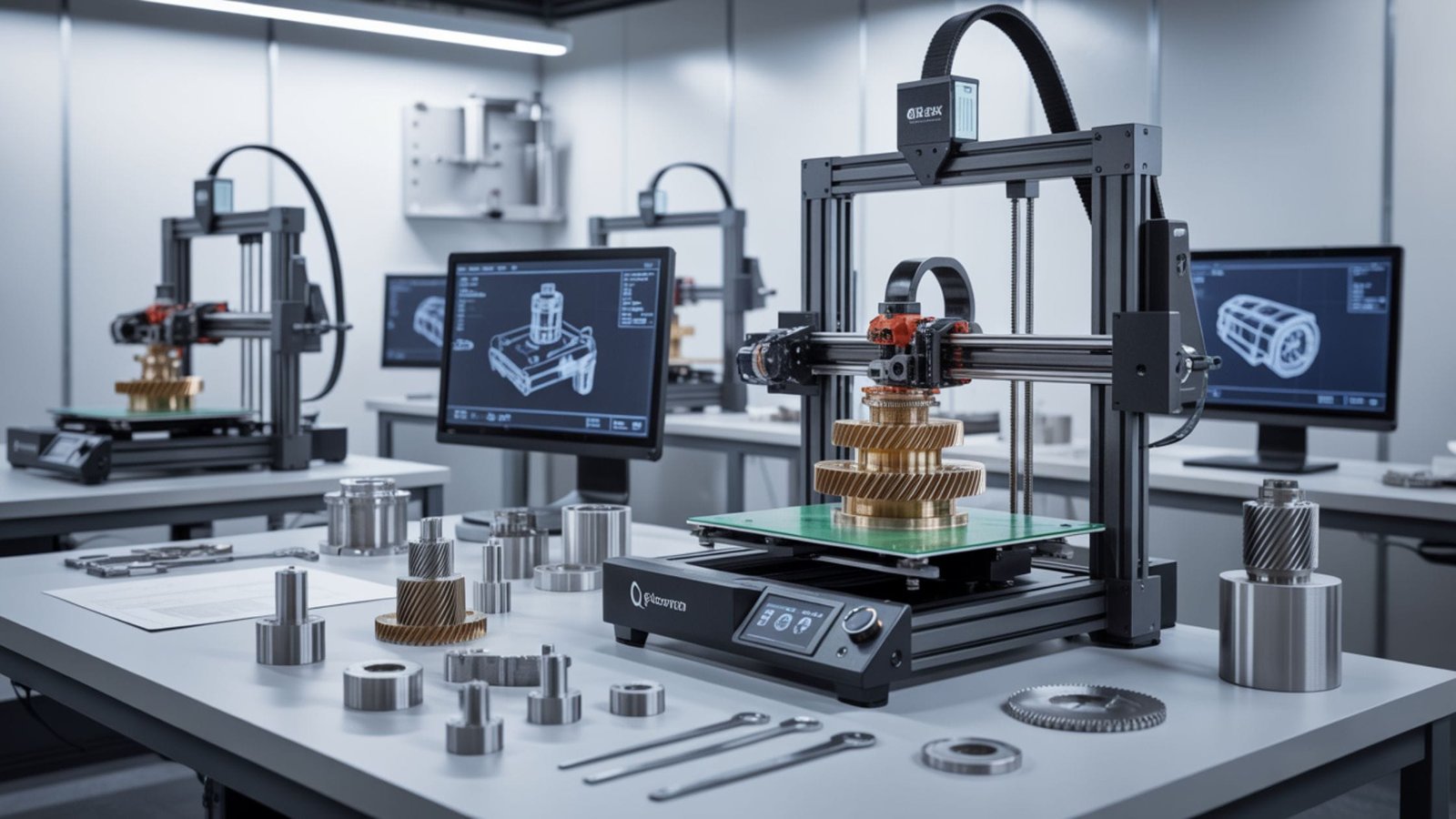

Companies test their designs quickly before investing in expensive mass production. Engineers can print a prototype in hours, test it, make changes, and print again the same day. Automotive companies like Ford use this to test engine components and interior parts. This approach reduces the time from initial concept to market launch by months.

2. Custom Manufacturing

3D printing excels at creating tailored products for specific customer needs. Medical device companies print custom implants that fit individual patients perfectly. Dental labs create personalized crowns and aligners daily. This customization level is impossible or too expensive with traditional manufacturing methods.

3. Complex Geometry Production

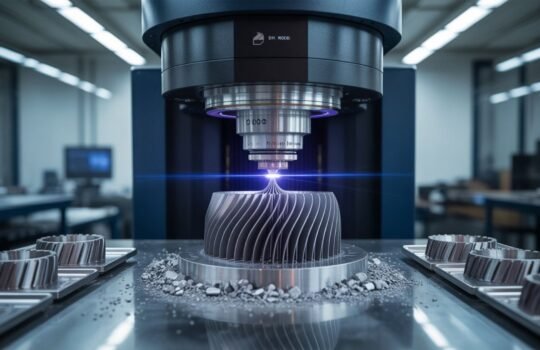

Traditional machining struggles with intricate internal structures and organic shapes. 3D printing product design allows engineers to build complex geometries that were previously impossible. Aerospace companies create lightweight lattice structures that reduce aircraft weight while maintaining strength. GE Aviation prints fuel nozzles with internal cooling channels that improve engine efficiency.

4. Cost Reduction

Companies save money by eliminating expensive tooling and molds. Traditional manufacturing requires costly setup that only makes sense for large production runs. With 3D printing, businesses produce small batches economically. Material waste drops significantly because the printer uses only what’s needed. On-demand production also reduces warehouse costs and unsold inventory.

5. Supply Chain Optimization

Manufacturers can print spare parts locally instead of shipping from distant warehouses. This dramatically cuts delivery times and transportation costs. Industrial equipment companies store digital files and print replacement parts on-site when machines break down. This approach minimizes downtime and keeps production lines running smoothly.

Benefits of 3D Printing Product Design for Industries

Companies adopting 3D printing product design gain several competitive advantages:

- Faster design iterations – Test and refine products in days, not months

- Lower upfront investment – No expensive molds or tooling required

- Design freedom – Create innovative shapes impossible with traditional methods

- Sustainability – Reduce material waste and energy consumption

- Shorter lead times – Move from concept to finished product quickly

- Risk reduction – Test market demand with small batches before scaling

Industries Leading in 3D Printing Product Design

- Aerospace and Aviation – Boeing and Airbus print lightweight brackets and interior components.

- Automotive Manufacturing – BMW and Volkswagen create custom jigs, fixtures, and end-use parts.

- Medical and Healthcare – Hospitals print surgical guides, prosthetics, and anatomical models.

- Consumer Goods – Adidas and Nike produce customized shoe midsoles for athletes.

- Industrial Equipment – Siemens and Caterpillar manufacture replacement parts on demand.

Common Questions About 3D Printing Product Design

- Is 3D printing product design expensive?

Initial costs are lower than traditional manufacturing. You don’t need expensive molds or tooling. For prototypes and small batches, 3D printing is highly cost-effective. As production volume increases, traditional methods may become cheaper.

- Can 3D printing replace traditional manufacturing?

It complements rather than replaces conventional methods. 3D printing excels at prototyping, customization, and low-volume production. For mass production of simple parts, traditional manufacturing remains more economical. Most companies use both approaches strategically.

- What materials work with industrial 3D printing?

Industrial printers handle diverse materials including engineering plastics like ABS and nylon, metals such as titanium and aluminum, photopolymer resins, and advanced composites. Material selection depends on the application’s strength, temperature, and durability requirements.

- How long does 3D printing product design take?

Print time ranges from hours to days depending on part size and complexity. A small prototype might print in 3-4 hours. Large industrial components can take 24-48 hours. This is still much faster than traditional tooling, which takes weeks or months.

Conclusion

3D printing product design is revolutionizing how companies develop and manufacture industrial products. From rapid prototyping to custom production, this technology offers speed, flexibility, and cost savings that traditional methods can’t match. As materials improve and printers become faster, more industries will adopt 3D printing as a core manufacturing strategy.

Ready to explore 3D printing product design for your business? Contact Tesseract today for expert additive manufacturing solutions that can transform your product development process.