The fashion world tosses out 92 million tons of clothes each year. Picture a garbage truck packed with textiles getting dumped every single second.

Major players like Adidas print shoe soles now. Artists craft crazy jewelry designs. A few brave souls even produce full outfits with these printers.

Curious how this gear makes fashion cleaner? Here’s the real story.

What Is 3D Printing for Fashion?

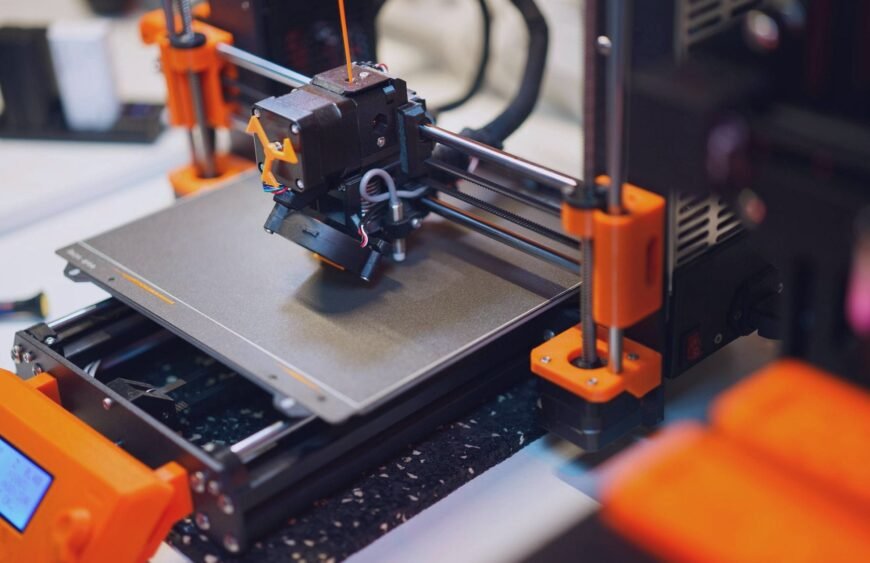

Picture a hot glue gun building stuff from bottom to top. Thin layers stack up until boom – you’ve got your item.

Fashion companies tap additive manufacturing for shoes, handbags, jewelry, and garments. These printers handle bendy filaments, reused plastics, and materials that rot away naturally.

You sketch your idea on a computer with CAD software, press print, then watch it appear. Zero sewing machines. Zero fabric bolts. Zero cutting stations.

Adidas cranks out shoe midsoles using this earth-friendly fashion tech. Artists build detailed accessories and tailored clothing that hands can’t create. Digital fabrication meets planet-conscious fashion making.

5 Ways 3D Printing Makes Fashion Sustainable

1. Zero Waste Production

Old-school fabric cutting dumps 15–20% of material. Like grabbing five shirts off the rack and chucking one right into the bin.

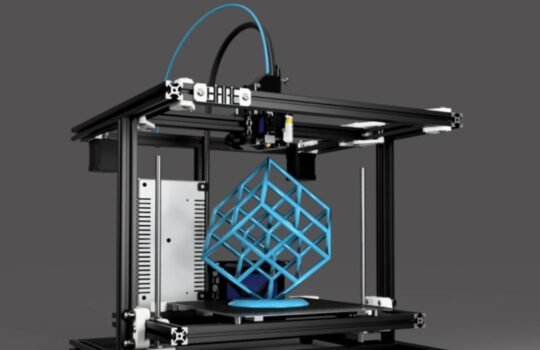

3D printing for fashion takes just what’s required. Printers lay down material drop by drop. Zero scraps land on floors. Zero leftover bits collect in corners.

Companies print stuff when ordered too. Customer wants earrings? You print those earrings. Zero cartons of dead inventory collecting dust in storage.

Adidas showed this works through their Futurecraft 4D shoes. Each sole gets printed to exact specs without losing a speck of material.

2. Reduces Carbon Footprint

Traditional factories belch out massive carbon clouds. Trucks and cargo ships then drag stuff between countries, torching more fuel.

Earth-friendly 3D printing switches things up. Set printers close to buyers. A Paris shop serves Paris folks. A Tokyo workshop handles Tokyo orders.

Printers gulp way less power than monster factory assembly lines. Zero huge ovens. Zero chemical dye tanks. Zero water drain.

Neighborhood additive manufacturing shrinks your carbon mark quick.

3. Uses Eco-Friendly Materials

This part really makes 3D printing for fashion pop. Pick materials that treat the planet right.

PLA thread starts as cornstarch. Nature breaks it down. Certain companies print with salvaged ocean plastic, flipping garbage into goods.

TPU brings flexibility minus oil-based cloth. Plant-grown polymers crush it for accessories and shoe parts.

Once your stuff dies, these nature-friendly materials head back to soil rather than rotting in dumps for two centuries.

4. Enables Custom Fit Design

Garments fitting just right stick around longer. You rock them constantly. They become favorites. They dodge the charity pile.

Digital building lets companies scan bodies and print stuff molded perfectly. Zero “kinda fits” sizing that bugs you.

Perfect fits also mean fewer send-backs. Less shipping garbage and gas wasted hauling boxes around town.

Folks baby custom garments. They fix them rather than ditch them. That’s the future sustainable fashion craves.

5. Supports Circular Fashion

Here’s the heavyweight point. 3D printed fashion goods get recycled straight back into printer fuel.

Printed bracelet snaps? Crush it up. Convert it to thread. Print fresh goods. It’s a never-ending loop keeping materials alive.

Printed bag needs a fix? Print only that broken bit instead of buying another whole bag.

This loop-around thinking means less digging for virgin materials and less junk filling dumps. Stuff lives multiple rounds instead of one fast ride from shop to trash heap.

Frequently Asked Questions

- Is 3D printed clothing comfortable to wear?Yeah, current 3D printed fashion feels good. Companies pick stretchy stuff like TPU that moves with bodies. Printed goods now feel gentle and let skin breathe during regular wear.

- How much does 3D printing for fashion cost?Tiny accessories run ₹1,500–₹8,000. Tailored shoes hit ₹15,000–₹40,000. Fancy designer stuff costs extra. Tags keep falling as tech spreads wider.

- Can 3D printed clothes be washed?Most 3D printed goods wash without fuss. Stick with chilly water and soft wash settings. TPU bits handle serious abuse. Always peek at your brand’s washing notes first.

- What materials are used in 3D printing for fashion?Popular picks include PLA (corn-made), TPU (stretchy), saved ocean plastics, nylon threads, and rot-friendly polymers. Each brings unique feels and green perks.

- How long does it take to 3D print fashion items?Small rings need 2–4 hours. Footwear requires 8–12 hours. Tricky outfits demand 24–48 hours. Time shifts based on size and fancy details.

Conclusion

3D printing for fashion tackles the industry’s enormous garbage crisis. Waste drops to nothing, pollution shrinks, and earth-safe materials take over.

Major names like Adidas ride this wave. Prices tumble down. Materials get better daily. Fashion goes green while banks stay happy.

Want your fashion brand going sustainable? Check out Tesseract‘s 3D printing services and jump in now.