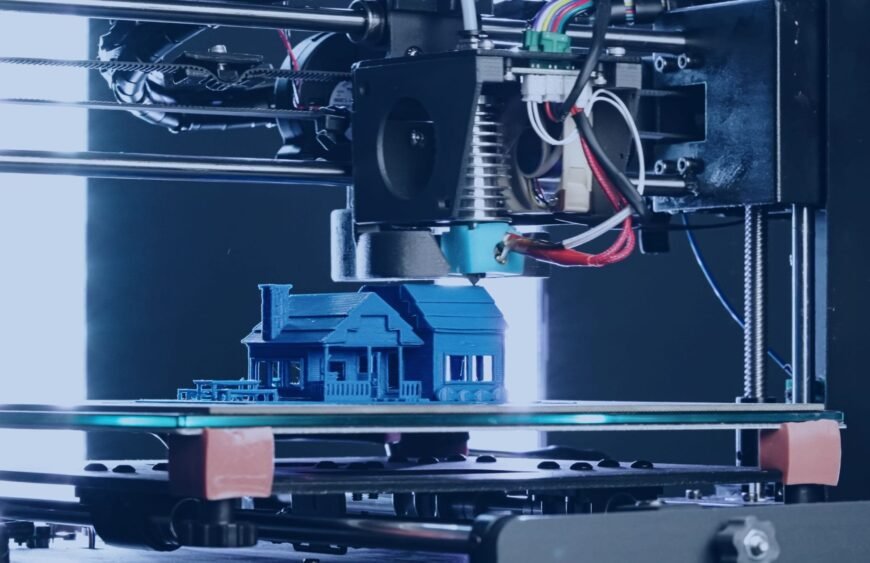

Furniture design in India is moving towards customization, sustainability, and faster production methods. 3D printing has become a game-changer, allowing designers and manufacturers to create unique furniture components with precision and reduced waste. But one of the most important factors that determines the success of a 3D printed furniture project is the choice of material. The right material ensures strength, durability, and the perfect finish, while also keeping costs practical for the Indian market.

In this blog, we’ll explore the best materials for 3D printed furniture components in India, covering both functional and decorative options.

1. PLA (Polylactic Acid)

PLA is one of the most widely used 3D printing materials. It’s biodegradable, eco-friendly, and affordable, making it popular in India. For furniture, PLA is best suited for lightweight decorative parts such as panels, trims, or design accents. However, it is not ideal for heavy load-bearing components since it can become brittle under stress.

2. ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong and durable thermoplastic often used in industrial 3D printing. It is highly impact-resistant, making it a good choice for chair frames, table legs, and structural components. The challenge lies in its printing process — ABS requires controlled temperatures to avoid warping, which means access to professional-grade 3D printers is necessary.

3. PETG (Polyethylene Terephthalate Glycol)

PETG offers the best of both worlds: strength like ABS and ease of printing closer to PLA. It is also moisture-resistant, which makes it a practical option for furniture used in Indian households with humid climates. PETG is increasingly becoming popular in India for functional furniture parts such as connectors, brackets, and durable panels.

4. Nylon (Polyamide)

Nylon is known for its tensile strength, flexibility, and wear resistance. It is ideal for producing functional furniture parts like hinges, joints, and components that require some degree of flexibility. Although slightly more expensive, Nylon is a smart choice when building long-lasting furniture that can withstand daily use.

5. Wood-Filled Filaments

Wood-filled filaments combine PLA with real wood fibers, producing furniture parts with a natural wooden finish. These materials allow designers to create pieces that look and feel like wood while offering the design flexibility of 3D printing. They are perfect for decorative furniture elements such as handles, trims, and tabletops that need an authentic touch of wood without the traditional carpentry work.

6. Carbon Fiber Reinforced Filaments

When strength and lightweight performance are priorities, carbon fiber reinforced filaments stand out. These are commonly used for high-stress furniture components like load-bearing supports or modular connectors. In India, premium furniture makers are experimenting with carbon fiber blends to create modern, sleek designs that are strong yet light.

7. Resin (SLA/DLP Printing)

Resins are typically used in SLA and DLP 3D printers, which are known for high precision and smooth finishes. Resin is excellent for intricate decorative parts such as detailed chair backs, lamp bases, or ornamental furniture accents. While not as strong as thermoplastics, resin parts stand out for their aesthetic appeal.

8. Metal-Infused Filaments (Copper, Bronze, Stainless Steel Blends)

Metal-infused filaments combine standard plastics like PLA or ABS with fine metal powders, giving the final print a metallic appearance and extra weight. These materials are excellent for producing decorative furniture accents such as knobs, handles, or trims. They bring a premium and modern look to furniture without the cost of full metal casting.

Conclusion

Choosing the right material is key to making 3D printed furniture both functional and beautiful. For eco-friendly and cost-effective designs, PLA and wood-filled filaments work well. For strength and durability, ABS, PETG, and Nylon are reliable choices. If you’re aiming for premium and high-performance furniture, carbon fiber filaments and metal-infused blends deliver the edge. And when it comes to detailed decorative work, resin offers unmatched finish quality.

In India, the future of furniture lies in combining modern 3D printing materials with sustainable practices. With the right choices, 3D printed furniture becomes both stylish and durable. For those ready to explore this potential, Tesseract’s advanced 3D printing and manufacturing services provide the expertise to turn innovative designs into reality.