Product design and manufacturing in India is changing quickly. More companies — whether they’re just starting out or have been around for years — are trying to figure out how to make small batches of products without overspending.

Traditional manufacturing doesn’t really work well for that. You’re still stuck paying for tooling and setup, even if you’re only making a handful of parts. For small runs, that just doesn’t make much sense — it feels like paying full price for half the work.

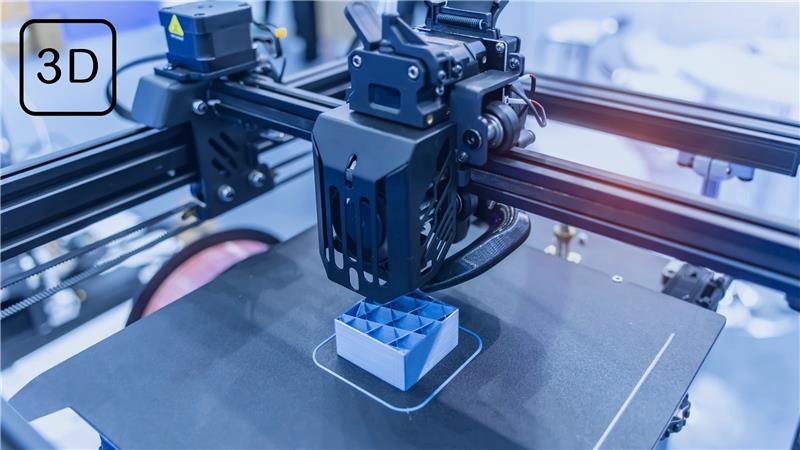

That’s where 3D printing has started to prove its worth. You don’t need moulds or a long setup process, which makes it way easier to get a product off the ground. And if you’re just starting with a few hundred pieces, it can actually save you a lot of trouble.

Now the big question — is 3D printing really the smarter choice for low-volume runs? Let’s explore that.

What is Low-Volume Production and Why is it Challenging?

Low-volume production usually means making anywhere from just a handful of units up to maybe a thousand. It’s pretty common when you’re testing a new product, doing a limited release, or building early versions for feedback. Customised parts also often fall into this category.

The tricky part is that traditional manufacturing methods aren’t really built for this. You still have to pay for expensive tooling and setup, even if you’re only making a few pieces. And those costs don’t change whether you’re making 10 or 10,000. So when you’re producing at a smaller scale, the cost per unit goes up fast, and for a lot of businesses, that just doesn’t add up.

How 3D Printing Solves the Low-Volume Problem

3D printing, or what some call additive manufacturing, builds parts straight from a digital file, one layer at a time. You don’t need moulds, dies, or any kind of complex setup — just the design and a machine that can handle it.

Forget the Tooling Headache

One of the best things about it? There’s no tooling involved. No upfront cost for moulds. That means you can start a small run without worrying about blowing your budget before making a single part.

Make Changes Without Starting Over

If you’re still working out the design, that’s no problem. Just tweak the file and print again. You don’t lose time, and you don’t have to start from scratch.

Custom or Not — Doesn’t Matter

You can print ten parts that are exactly the same or ten that are totally different. The process doesn’t care. That flexibility is a game-changer for low-volume projects.

Print When You Need To

No need to stock shelves or fill up storage. Print what you need, when you need it. It’s cleaner, leaner, and way less stressful.

When is 3D Printing Cost-Effective?

Let’s consider a simple comparison. In traditional manufacturing, even a basic plastic part requires tooling, setup, and a minimum order quantity to make the price reasonable. In low volumes, these fixed costs are too high.

With 3D printing, you can produce only as many parts as you need without any tooling. Although the per-part cost may be slightly higher at scale, for small batches, the total project cost often works out to be lower.

Factors Affecting Cost-Effectiveness

- Quantity required

- Part complexity

- Material selection

- Surface finish and strength expectations

Real-World Example from Tesseract

One of our clients, a hardware startup, needed 300 product enclosures for a beta launch. They explored traditional manufacturing but found the tooling costs and lead time too high.

At Tesseract, we used Multi Jet Fusion (MJF) technology to deliver the parts within a week, with no tooling involved. The client didn’t just save on cost — they also cut down delivery time and launched sooner than expected. And because there was no need for tooling, they stayed well within their budget.

This isn’t a one-off case either. We’ve seen 3D printing help many clients move faster, avoid delays, and keep things lean during the early stages of product development.

Situations Where 3D Printing May Not Be Ideal

Although 3D printing offers many advantages, it is not always the right fit.

High Volumes

When you need thousands of identical parts, traditional methods like injection moulding become more economical due to their low per-part cost at scale.

Specific Material or Compliance Needs

Some applications in medical, food, or aerospace sectors require certified materials and finishing processes that may not be fully supported by 3D printing.

In such cases, it is important to assess your priorities and choose the right method accordingly.

Our Advice at Tesseract

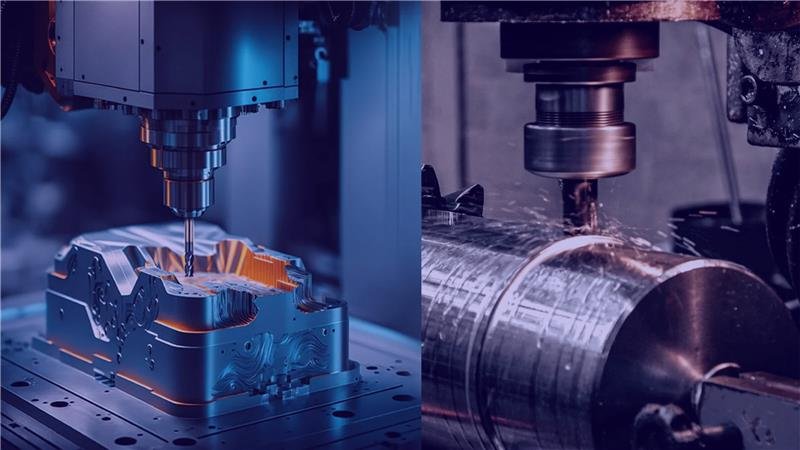

At Tesseract, we help businesses navigate the manufacturing process by offering practical, cost-driven guidance. Our team looks at every project individually and helps you decide whether 3D printing, CNC machining, or injection moulding is the right fit.

Sometimes, we recommend a hybrid approach. For example, using 3D printing for your pilot batch and switching to traditional manufacturing once the design is finalised and demand increases.

The goal is always the same: save cost, reduce risk, and get your product to market faster.

Final Thoughts

So, is 3D printing cost-effective for low-volume production?

Yes, in many cases, it is not only cost-effective but also faster, more flexible, and better suited for rapid development. Especially when you are producing less than 1,000 units or need to test and iterate quickly, 3D printing offers clear advantages.

However, the right answer depends on your specific part, material, and business goal. That is why a careful evaluation is always recommended.

Ready to Explore Your Options?

If you have a low-volume production need and are unsure which manufacturing route to take, speak to our team at Tesseract.