3D printing in healthcare has rapidly emerged as a game-changer in the medical device industry. From producing intricate surgical models to creating custom 3D-printed medical devices like implants and prosthetics, this technology is reshaping how healthcare professionals approach patient care. By enabling faster rapid prototyping in healthcare and cost-effective medical device production, 3D printing has opened up exciting new opportunities for improving healthcare outcomes.

In this blog, we’ll explore how additive manufacturing has transformed the medical device landscape, highlighting key benefits, real-world examples, and what the future holds.

The Evolution of 3D Printing in Medical Applications

3D printing in medical applications started with rapid prototyping to quickly test new device designs. Over time, additive manufacturing has evolved into a tool for creating patient-specific solutions like implants, prosthetics, and surgical models. Today, 3D printing medical applications are all about personalizing care, improving outcomes, and helping healthcare providers bring innovative ideas to life.

Key Benefits of 3D Printing for Medical Device Manufacturing

- Enhancing Innovation and Efficiency: 3D printing in medical device manufacturing brings major benefits.

- Customization and Personalization: It enables the production of custom 3D-printed medical devices that fit each patient perfectly. From prosthetics to implants, these patient-specific devices lead to better comfort and outcomes.

- Reduced Costs and Faster Development: 3D printing also lowers costs and speeds up design. With rapid prototyping in healthcare, manufacturers can quickly test and refine devices without expensive tooling. This makes cost-effective medical device production easier, even for small batches.

Real-World Examples of 3D Printing in Medicine

Success Stories and Case Studies

The power of 3D printing in healthcare is best seen in real-world examples and case studies that highlight its transformative impact.

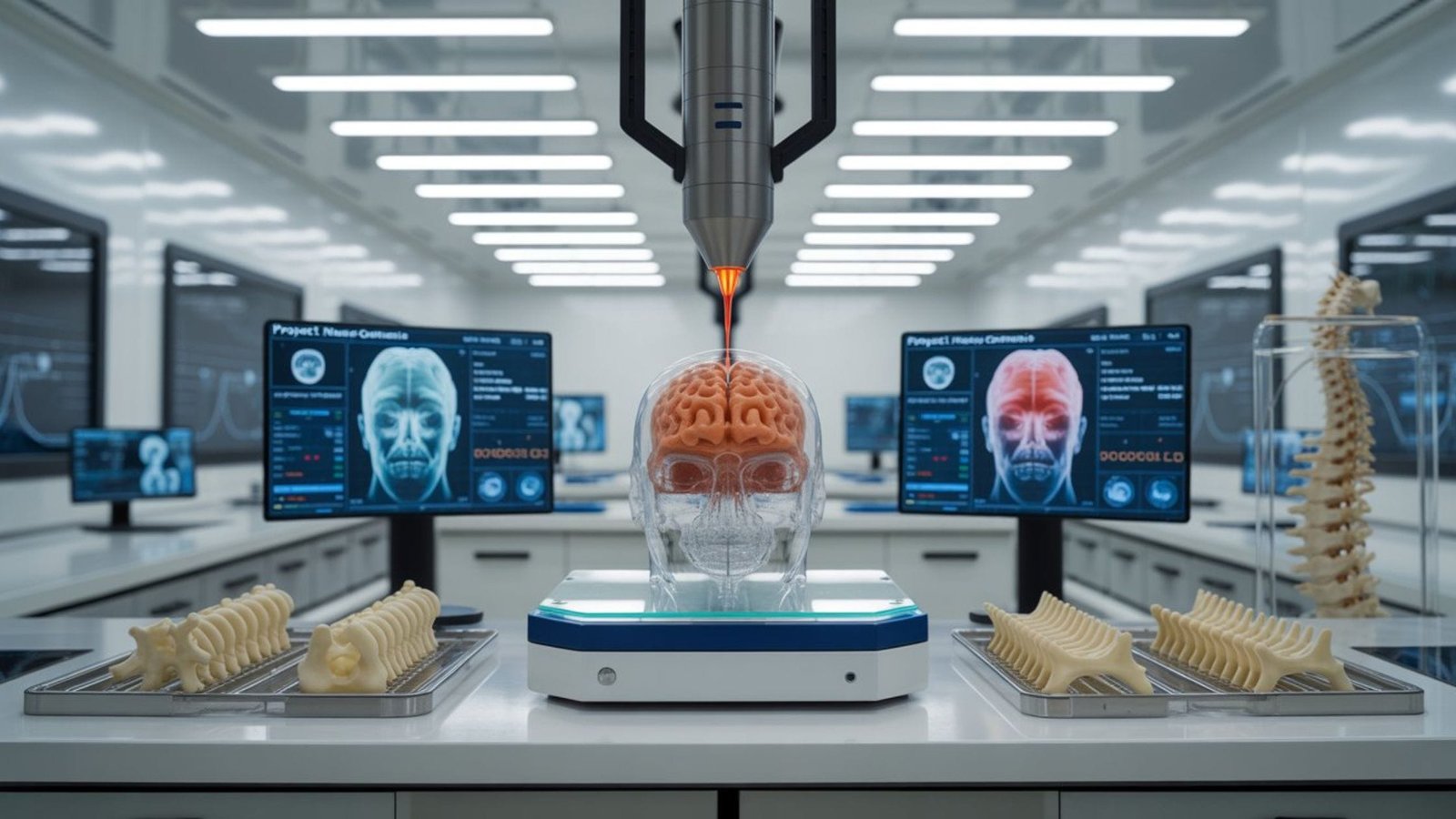

3D-Printed Implants and Prosthetics

From custom cranial implants to dental prosthetics and orthopedic devices, 3D printed implants and prosthetics are improving patient outcomes by offering a perfect fit and biocompatibility.

Surgical Planning and Models

Hospitals are using 3D-printed surgical guides and pre-surgical models to plan complex procedures. These tools boost surgical precision and improve patient safety, showing the real power of 3D printing in healthcare today.

Materials and Technologies Shaping the Future

Biocompatible and Bio-Inspired Materials

- Medical-grade polymers, metals, ceramics, and bioinks.

- Ensure safe, durable, and patient-specific medical devices.

- Support long-term implantation and patient safety.

Cutting-Edge 3D Printing Techniques

- Technologies include SLS, SLA, FDM, and emerging bioprinting.

- Enable creation of complex, high-precision structures.

- Power the shift to personalized, patient-centered medical devices.

Regulatory Considerations and Future Outlook

Navigating Compliance and Standards

As 3D printing in healthcare expands, regulatory standards like those from the FDA are key to ensuring safe and effective medical devices. Compliance helps protect patients and ensures consistent quality across the industry.

The Road Ahead

The future of 3D printing in healthcare is bright, with trends like bioprinting and advanced materials paving the way for even more personalized treatments. As technology and materials evolve, 3D printing will keep pushing the boundaries of patient care.

Bringing It All Together

3D printing has truly transformed the medical device industry, offering customization, faster development, and more effective treatments. From surgical models to patient-specific implants, this technology has opened up exciting possibilities for personalized care. As 3D printing in healthcare continues to evolve, it promises to bring even more innovation and better outcomes for patients. Let’s embrace this powerful tool and explore the future of medical device manufacturing together!