FDM Printing (Fused Deposition Modeling) has evolved from a rapid prototyping tool into a reliable manufacturing technology. Initially popular for creating plastic parts, FDM is now gaining traction in industrial settings for functional components, tooling, and even metal part production. As manufacturers seek more cost-effective and agile production methods, FDM creates functional metal components—offering a cost-effective entry point into metal additive manufacturing.

Can FDM Printers Print Metal?

Yes—but not how most people imagine.

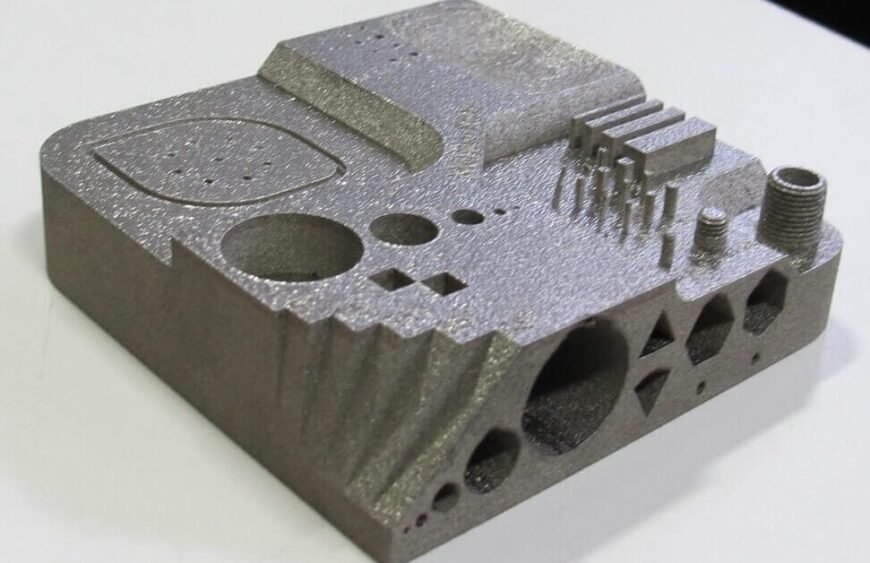

Standard FDM Printers can’t extrude molten metal. Instead, they use metal-polymer composite filaments—metal powder bound with thermoplastic. After printing, the object undergoes debinding and sintering, which removes the binder and fuses the metal particles into a solid metal part.

This process transforms a plastic-bound print into a nearly pure metal object, enabling manufacturers to produce durable parts without high-end metal AM systems.

What Are Composite Metal Filaments?

Materials like BASF Ultrafuse 316L or Markforged’s proprietary filaments are designed specifically for metal FDM. These filaments are typically made of 80–90% metal powder, with the rest being a binder that allows for extrusion through standard FDM nozzles.

Post-Processing Steps

After printing, parts go through:

- Debinding – Chemically or thermally removing the polymer binder

- Sintering – Heating the part in a furnace to bond the metal particles

The final result is a dense metal part with properties comparable to Metal Injection Molding (MIM).

How Functional Are These Metal Parts?

Once sintered, FDM metal parts can achieve:

- Up to 99% metal density

- High strength and durability

- Corrosion and heat resistance

- Mechanical properties suitable for industrial use

While not as precise as laser-based systems, they’re ideal for functional prototypes, tooling, and low-volume parts—where speed and cost matter more than micron-level detail.

FDM Metal Printing vs. Traditional Metal AM

How It Compares to DMLS and Binder Jetting

Traditional methods like Direct Metal Laser Sintering (DMLS) or Binder Jetting offer exceptional surface finish, detail, and material range—but come at a high cost. These systems require expensive equipment, controlled environments, and trained operators.

FDM metal printing, on the other hand, offers:

- Lower equipment and material costs

- Safer, powder-free operation

- Simpler setup and maintenance

It’s not a replacement for high-end AM but offers a practical, affordable option for in-house metal part production.

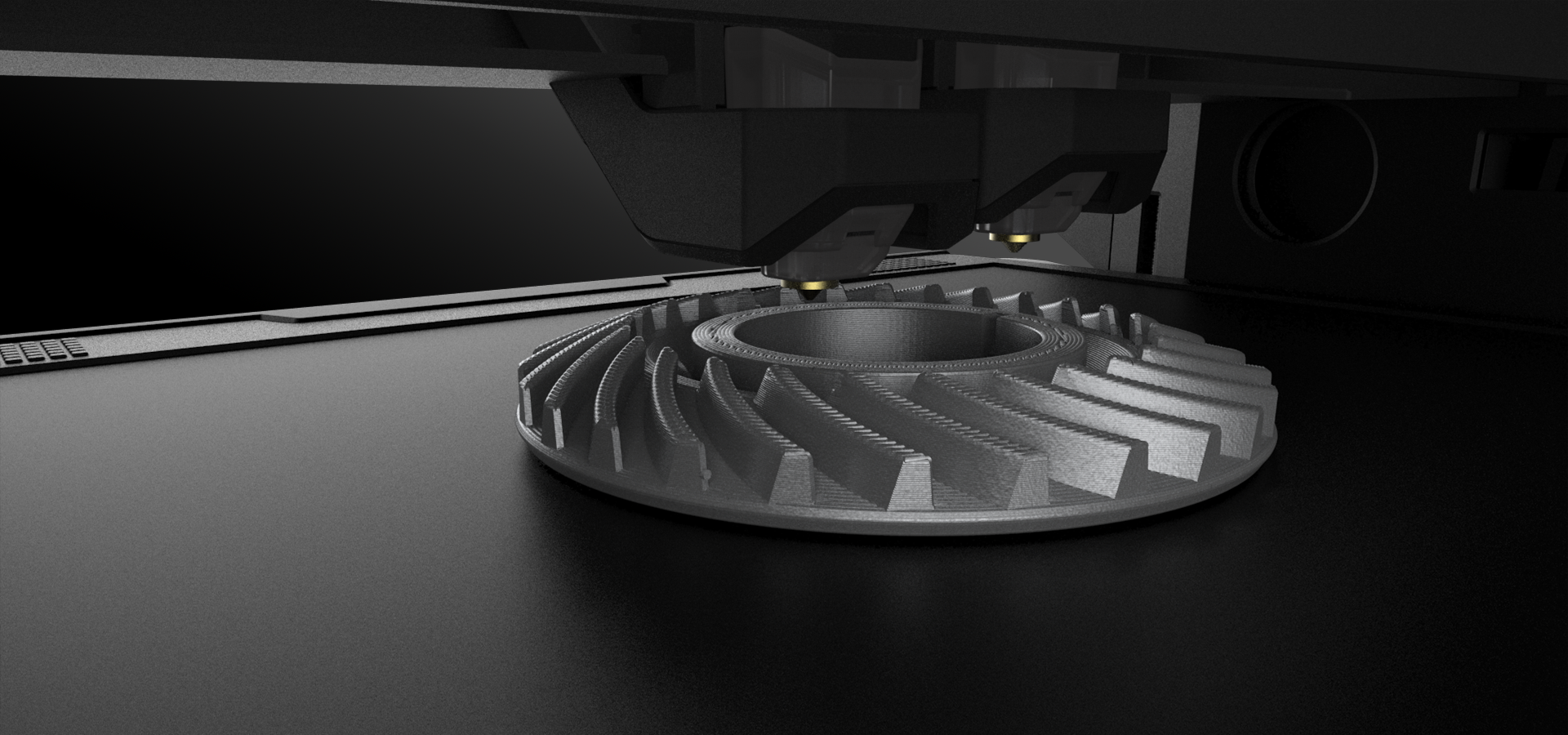

Best Use Cases for Metal FDM

Metal FDM printing is gaining adoption in industries looking for faster, more agile manufacturing methods. It’s particularly suited for:

- Jigs and fixtures for assembly lines

- Custom tooling for CNC and injection molding

- Functional prototypes for metal validation

- Low-volume replacement parts for legacy systems

In these areas, FDM provides shorter lead times, design freedom, and reduced outsourcing.

Design Considerations for Success

Metal FDM isn’t plug-and-play—it requires careful design and process awareness. Key design tips include:

Shrinkage Compensation

Printed parts shrink 15–20% during post-processing. Designs must account for this to maintain dimensional accuracy.

Wall Thickness

Thin walls (<1.5 mm) can deform during sintering. Use robust geometries to ensure stability.

Support and Orientation

Overhangs still need supports—designed to withstand sintering and easy to remove post-processing.

Geometry Restrictions

Avoid enclosed voids, sharp internal corners, or fragile structures that can complicate debinding or cause cracking.

A well-thought-out design and workflow are crucial to achieving reliable, high-quality results.

The Future of FDM Metal Printing

Where It’s Heading

While it doesn’t yet rival DMLS in precision, metal FDM is closing the gap with advances in:

- Filament quality – higher metal content and improved flowability

- Automated post-processing systems

- Expanded material options – copper, titanium, tool steels

- Integrated software workflows – streamlining print-to-part processes

These innovations are making metal FDM increasingly attractive for agile, localized production.

A Bridge Between Prototyping and Production

Metal FDM fills the gap where traditional manufacturing and high-end 3D printing fall short. It enables:

- Rapid iteration of functional prototypes

- Customized tooling and parts with low setup costs

- On-demand production to mitigate supply chain risks

For manufacturers embracing Industry 4.0, metal FDM is a strategic capability—not just a trend.

Conclusion

FDM metal printing blends affordability, accessibility, and industrial functionality, making it a viable solution for:

- Prototyping

- Tooling

- Small-batch production

While not a replacement for every metal AM process, it shines in cost-conscious, fast-moving environments. At Tesseract, we help manufacturers adopt tailored FDM solutions to bring metal part production in-house—bridging the gap between design innovation and real-world manufacturing.