Fused Deposition Modeling, or FDM, has long been the most widely adopted 3D printing technology due to its accessibility, cost-effectiveness, and versatility. In 2025, FDM continues to evolve at a rapid pace, driven by innovations in materials, hardware, and intelligent automation. Whether you are a design engineer, product developer, or hobbyist, understanding the latest FDM trends is key to staying competitive.

At Tesseract, where cutting-edge design meets manufacturing excellence, we keep a close watch on industry developments. Here is a roundup of the most impactful FDM 3D printing trends shaping 2025.

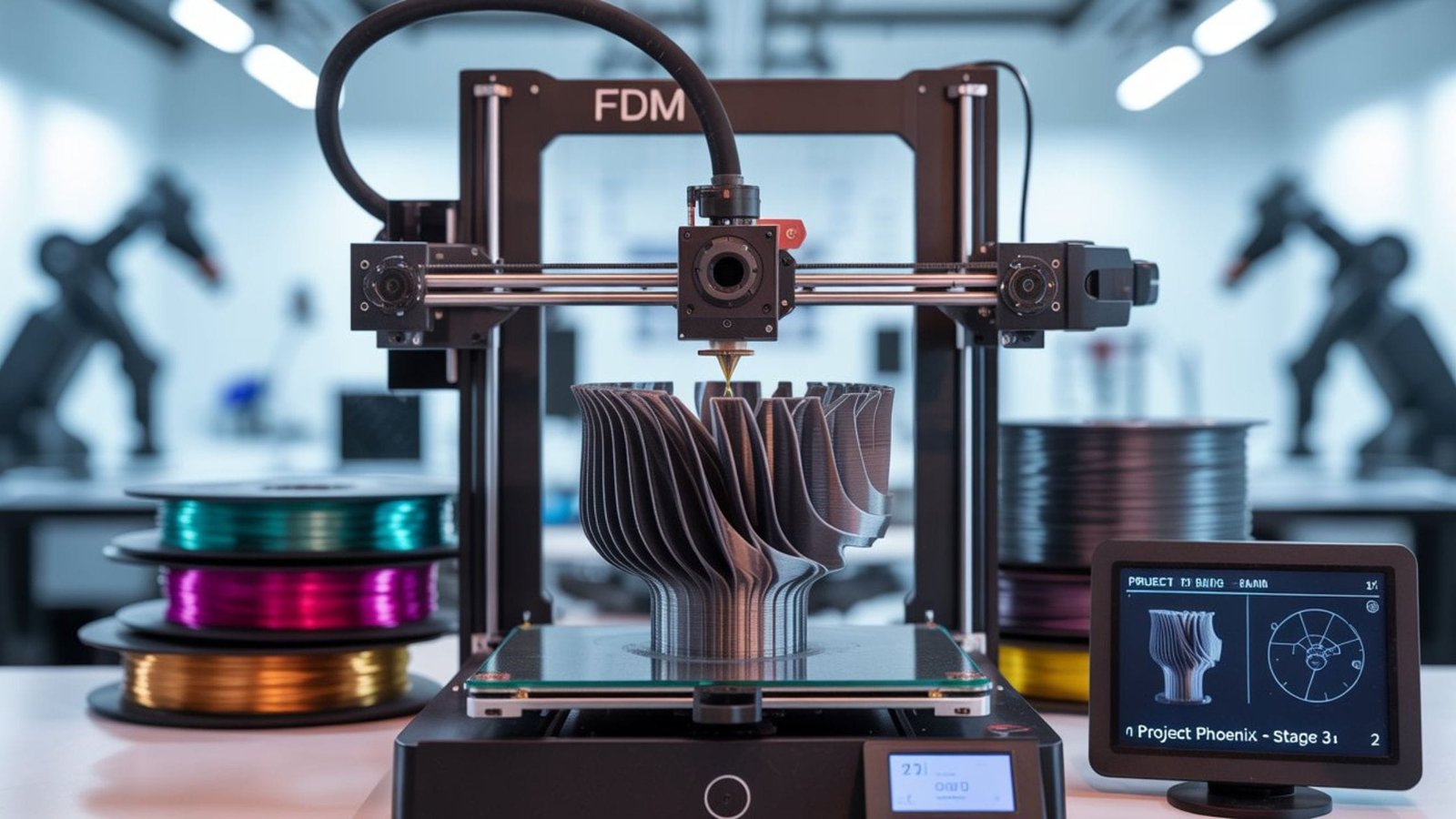

1. High-Performance Materials Take the Lead

One of the most notable trends is the increased use of high-performance thermoplastics in FDM printing. Materials such as PEEK, PEKK, ULTEM, and PC are gaining popularity due to their superior strength, heat resistance, and chemical durability. These filaments are expanding FDM’s role in demanding sectors like aerospace, automotive, and medical devices.

Composite filaments, including carbon-fiber and glass-fiber reinforced variants, are also seeing widespread adoption. These materials allow for the production of lightweight yet robust functional parts that were once only possible with traditional manufacturing methods.

2. Speed and Productivity Enhancements

In 2025, speed is no longer a compromise in FDM printing. Modern machines powered by Klipper firmware are achieving high print speeds without sacrificing surface quality. Features such as input shaping and pressure advance significantly reduce artifacts like ghosting and ringing.

Independent dual extruder (IDEX) systems and multi-nozzle printers are also boosting productivity. They allow for the simultaneous printing of multiple parts or soluble support structures, enabling faster iteration and less post-processing time.

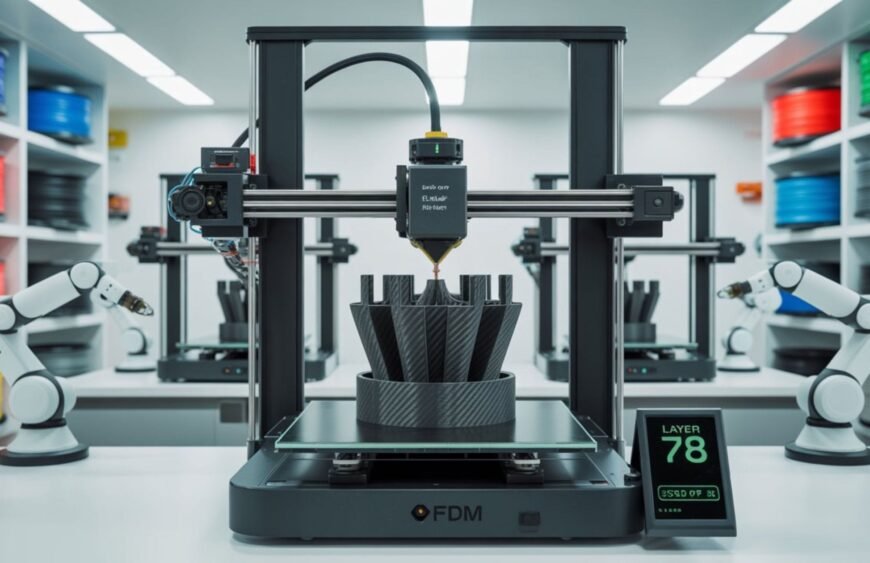

3. Automation and Smart Monitoring Integration

Automation is now deeply embedded in the FDM workflow. AI-powered tools are increasingly used for real-time failure detection, print correction, and slicing optimization. This reduces material waste and minimizes downtime.

IoT-connected printers provide remote monitoring, cloud-based management, and usage analytics. Smart features such as auto bed leveling, filament runout detection, and automated Z-offset calibration have become standard in mid to high-end FDM printers.

4. Sustainable and Recycled Filament Usage

Sustainability is no longer a side consideration. More manufacturers and users are turning to eco-conscious filaments such as PLA+, PETG-R, and even algae-based bioplastics. These options provide reliable performance while reducing environmental impact.

Additionally, desktop filament recycling systems are becoming accessible, allowing users to create new filament from failed prints or production scrap. This closed-loop approach supports a more circular manufacturing model within the FDM ecosystem.

5. Hybrid Manufacturing Workflows

Hybrid manufacturing, combining FDM with CNC milling, laser engraving, and post-processing technologies, is becoming more prevalent. These workflows enable the creation of dimensionally accurate and aesthetically refined parts.

Techniques like vapor smoothing, epoxy coating, and electroplating are used to enhance the surface finish and mechanical strength of FDM prints. This is particularly useful for end-use parts in low-volume production or functional prototyping.

6. Micro and Precision FDM Printing

Micro-FDM is emerging as a subtrend within the industry. By using precision-engineered nozzles and fine motor controls, manufacturers can now print small, intricate parts with improved dimensional accuracy.

This capability is crucial for applications in wearable electronics, microfluidics, and custom surgical guides. As demand for compact and complex components grows, micro-FDM is proving its value in new markets.

7. Open-Source Ecosystem Evolution

The open-source movement continues to fuel innovation in the FDM world. Printers that support open hardware and firmware such as Marlin, RepRap, and Klipper are attracting a growing community of developers and advanced users.

This flexibility allows for deep customization, modular upgrades, and continuous improvement. Businesses are leveraging open-source platforms to create application-specific machines at a lower development cost.

Conclusion

FDM 3D printing in 2025 is defined by smarter, faster, and more sustainable innovation. From high-performance materials to AI-enhanced workflows and micro-precision parts, the technology is more capable than ever before.

At Tesseract, we are committed to pushing the boundaries of what is possible with FDM. Whether you are building the next breakthrough product or optimizing your manufacturing process, we are here to support your vision with our design and fabrication expertise.

Stay ahead of the curve. Explore how Tesseract can bring your next idea to life with the power of advanced FDM 3D printing.