3D Printing in Architecture: Bringing Designs to Life

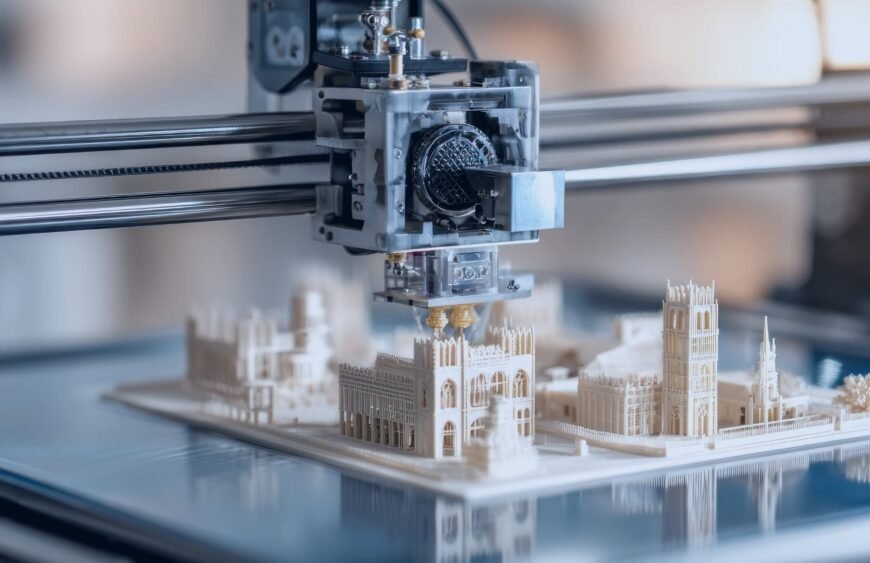

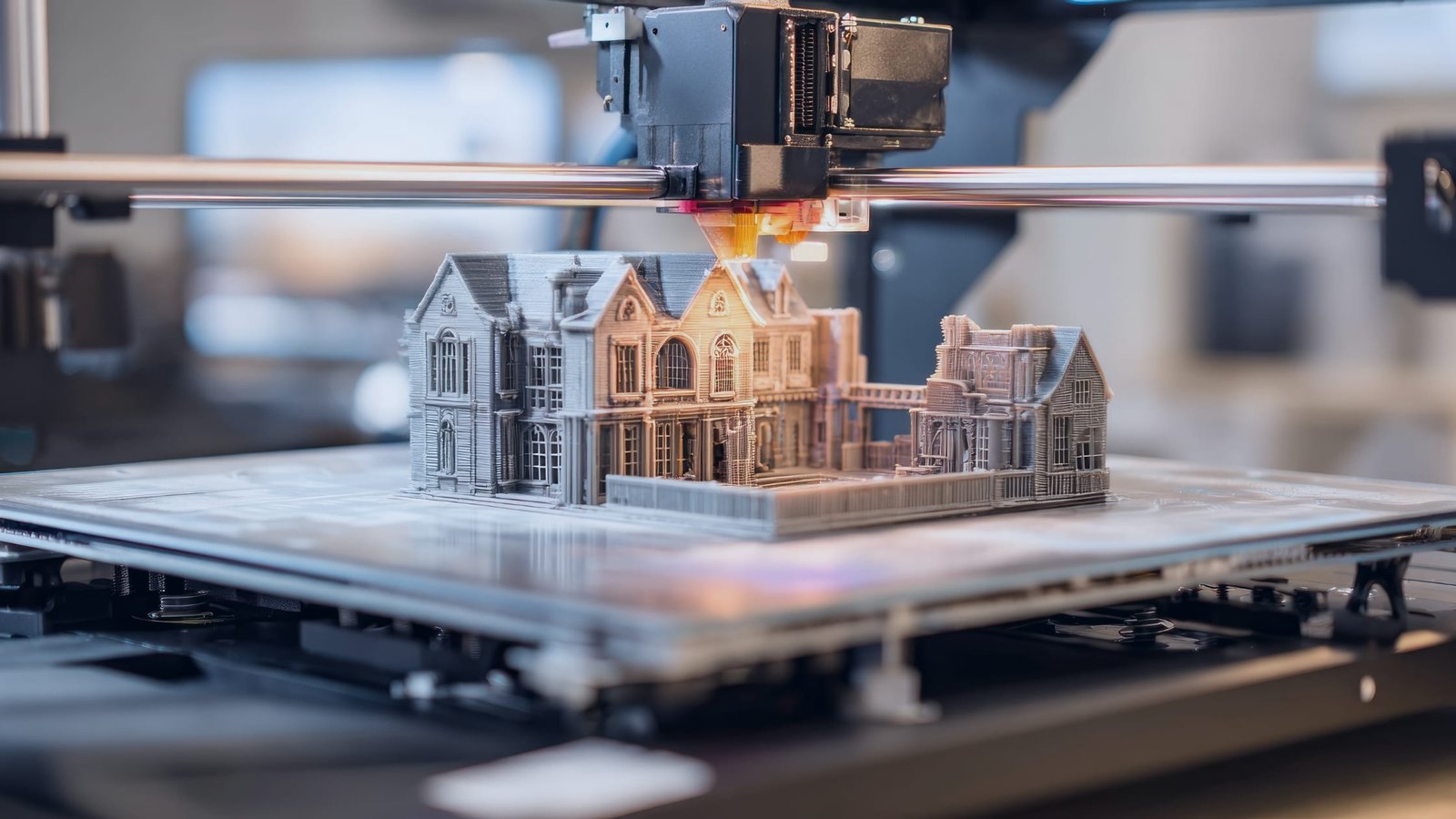

Sometimes a drawing isn’t enough to understand a building. You want to see it, touch it, and study its shape. 3D printing in architecture makes that possible. You can take a digital design and build a small, physical model that looks and feels real. It helps you find design issues before construction starts. You can test different forms, materials, and scales to see what works best. The process is quick, clean, and reduces waste.

For many professionals, architectural 3D printing is now part of everyday design work. It brings ideas to life and shows exactly how a concept will perform in the real world.

What is 3D Printing in Architecture?

In design work, seeing a model tells you more than a drawing ever could. 3D printing gives that option. You take the file you already built on your computer and print it as a small, solid version. The printer adds one thin layer at a time until the shape is complete. It’s simple to check spacing, size, and flow. When something looks off, you can adjust and print again without having to start over.

Why Architects Use 3D Printing

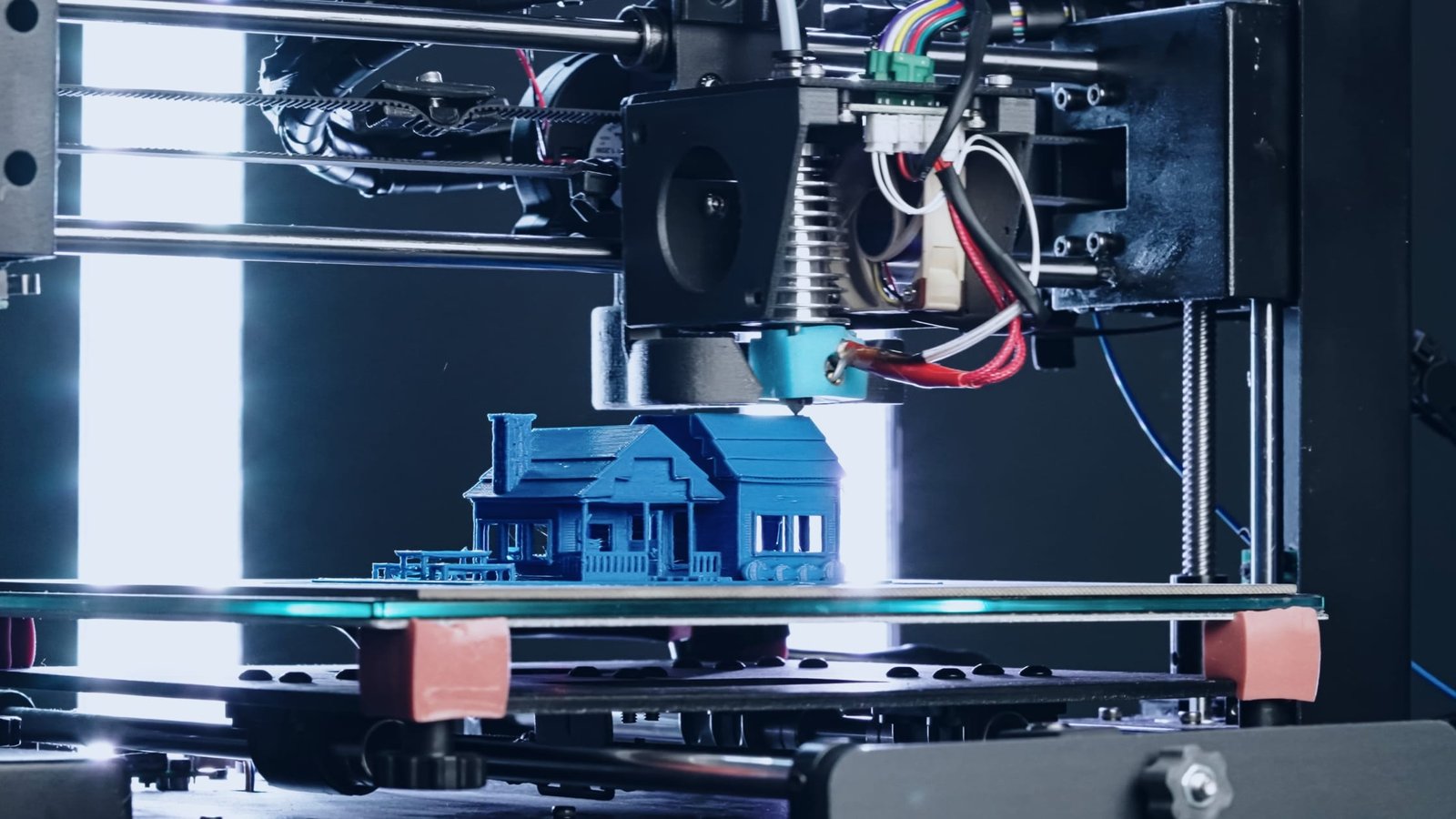

In most projects, time and accuracy matter. 3D printing helps with both. You can take a design and turn it into a model without long manual work. The machine handles the detail and keeps every line true to the plan. It’s easy to spot problems early and fix them fast. You use fewer materials and keep better control over each design. Many architects now rely on this method to turn digital plans into clear, hands-on models they can review and improve with ease.

How 3D Printing Works in Architecture

Step 1: Create the 3D Model

First, you make your design in CAD or BIM. Nothing fancy, just the layout done right. You check that all the parts fit.

Step 2: Prepare the File

Then, you move it into the slicer. That software splits it into layers so the printer knows what to do. You look it over once more before starting.

Step 3: Choose the Material

Now you pick what to print with. PLA is fine for quick runs. Resin looks cleaner. Use ABS when you want something tougher.

Step 4: Print the Model

You start the print. It builds slowly, one thin layer after another. You can see the form appear gradually.

Step 5: Clean and Finish

When it’s done, you take it off the bed, pull off the supports, and sand rough spots. The model feels real in your hand. It’s ready to study or show.

Popular Materials for Architectural 3D Printing

PLA

This one’s used a lot. It prints fast and doesn’t cause much trouble. Good for rough models when you just want to see the shape.

Resin

You use resin when you want detail. The surface comes out smooth and clean. It’s great for showing a finished look or texture.

ABS

ABS is stronger. It takes more heat and doesn’t break easily. It’s handy when the model needs to hold weight or stand up to handling.

Gypsum

This material can show color and surface texture better than most. It works when you need something that looks close to the real finish.

Nylon

Nylon bends a little but stays tough. It’s not used often, but it helps when parts need to move or stay flexible.

Future of 3D Printing in Architecture

3D printing is moving fast in the design world. Printers are now quicker, larger, and more accurate, making them useful beyond model making. Some teams already use them to print building parts and small structures.

Key Changes Ahead

- Bigger printers will handle full-scale construction.

- New eco-friendly materials will cut waste.

- Designs will link directly to printers for instant updates.

- Costs will drop as the technology becomes standard.

FAQs About Architectural 3D Printing

Q1. What do architects use 3D printing for?

A. It’s mainly for testing ideas. You print a small version of the design to see how it looks and fits together before anything gets built.

Q2. How long does it take to print one?

A. That changes a lot. A simple model might be done by the end of the day. A larger one can run overnight or longer.

Q3. What kind of materials do you use?

A. PLA works fine for quick prints. Resin looks cleaner and shows more detail. Some use tougher materials when the model needs to handle stress.

Q4. Can it be used for full buildings?

A. Yes, and it’s already happening. Some teams print walls and small houses using concrete mixes. It’s still early, but it’s real.

Q5. Why do architects like using it?

A. It saves time, gives better accuracy, and makes changes easier. You get to see your design in real form, not just on a screen.

Conclusion

3D printing is changing how design work gets done. It helps turn drawings into real models that you can see and hold. You can test ideas, fix small issues, and make better choices before building begins. It cuts down time and waste while keeping accuracy high. This way of working is becoming standard across the field.

If you want to bring your designs to life, reach out to Tesseract. We help architects and designers turn digital plans into strong, detailed 3D models built to match their vision.