The toy industry has always evolved alongside major technological shifts. From wooden carvings to plastic moulds, each era introduced new ways to bring imagination to life. One of the most transformative technologies in recent years has been 3D printing. What began as an industrial prototyping tool is now revolutionising how toys are designed, developed, and delivered. In India, where toy manufacturing is gaining government support and global recognition, 3D printing presents a unique opportunity for service providers to redefine what is possible in play.

The Pre-3D Printing Toy Industry — A Quick Throwback

Traditionally, toys were manufactured using processes like injection moulding and casting. These methods, although suitable for mass production, required a high upfront investment and lacked design flexibility. In India, many toy manufacturers faced challenges due to:

- Heavy dependence on imported machinery and moulds

- High tooling costs discouraged frequent product updates

- Long lead times for design changes and mass production

As global markets moved toward greater personalisation and shorter product cycles, these limitations made innovation difficult without major capital investment.

The Arrival of 3D Printing — A Disruptive Innovation

3D printing, also known as additive manufacturing, made its debut in the toy world through rapid prototyping. Brands like Hasbro and Mattel used it to reduce development timelines and costs. Designs that once took weeks could now be tested within hours. Indian toy startups and creative agencies have started following suit, using desktop printers to test character models, educational toys, and mechanical parts. This shift from static design to agile creation has opened new doors for the Indian toy ecosystem.

Key Innovations That Shaped the Industry

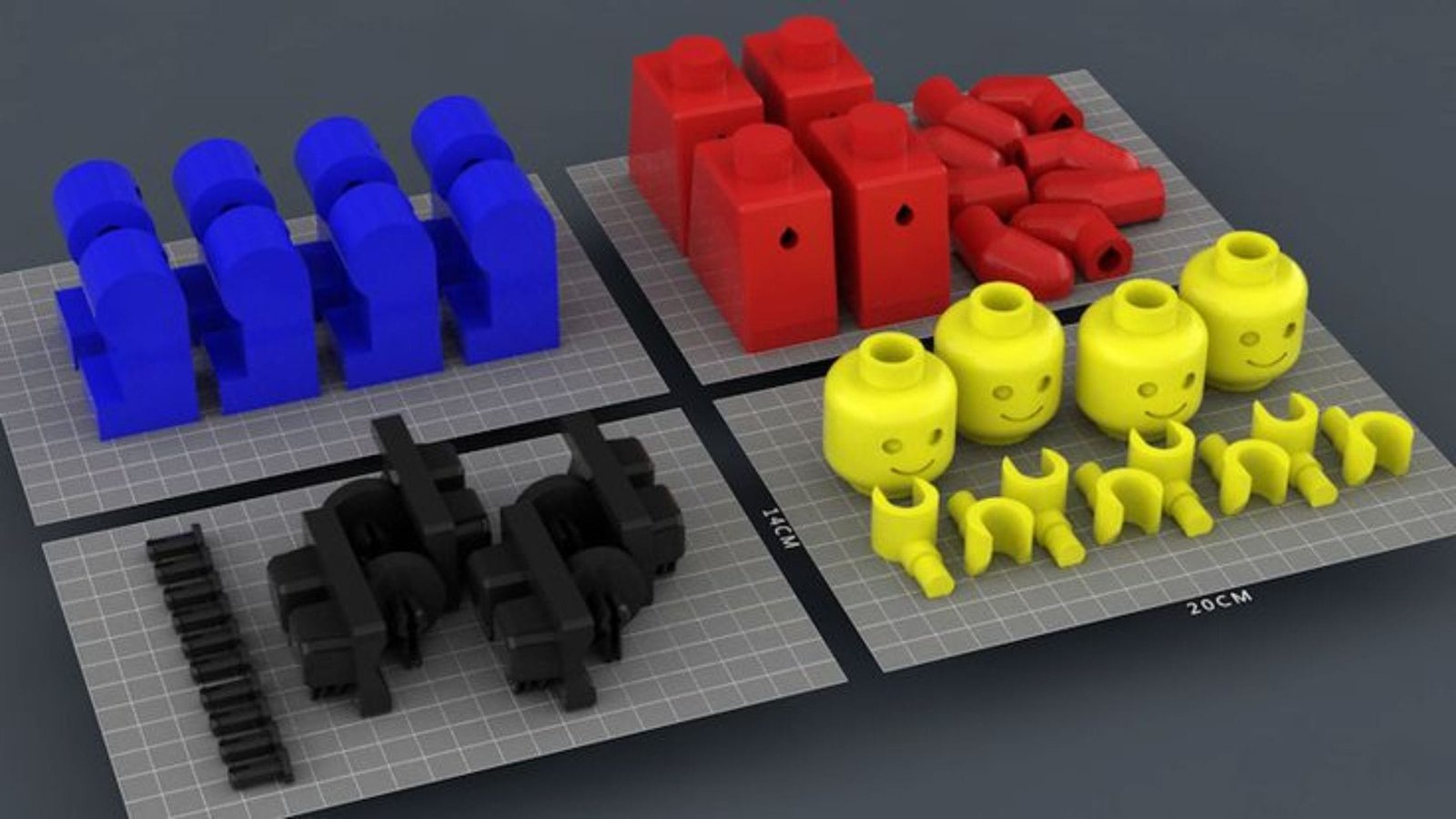

Customisable Action Figures and Dolls

3D printing has made personalised toys more accessible than ever. Indian toy startups are tapping into this niche by offering:

- Custom facial features or names on action figures

- Personalised dolls for gifting or collections

- Unique accessories based on customer preferences

These low-volume, high-value products are ideal for online toy businesses and print-on-demand models.

Educational STEM Toys

Indian edtech startups and educators are increasingly using 3D-printed STEM kits in classrooms. These toys help children visualise mechanical and scientific concepts, especially in hands-on workshops. Modular toys, printed puzzles, and simple machines can all be designed, tested, and refined rapidly, giving children interactive learning tools rooted in real-world mechanics.

Open Source and Maker Culture

Platforms like Thingiverse have inspired hobbyists and indie designers to experiment with 3D printing. Across India, makerspaces and creative communities are emerging in cities like Bengaluru, Pune, and Ahmedabad. This trend is fueling demand for local 3D printing services that can bring open-source toy designs to life for end users and creators alike.

Impact on Indian 3D Printing Services

The growth of custom toys and short production runs has opened up new business for 3D printing service providers in India. They are now supporting a wide range of clients, including:

- Toy designers need quick prototype iterations

- Educators and schools looking for custom learning kits

- E-commerce brands launching niche toy products

Technologies like FDM and resin printing are being used based on design detail and durability. Affordable pricing, fast turnaround, and nationwide delivery have made local 3D printing services essential partners for toy-focused entrepreneurs.

Cost, Time, and Creativity — The Winning Trio

One of the biggest advantages of 3D printing is how it balances cost efficiency, speed, and creative freedom. With no need for tooling or moulds, toy creators can launch products with minimal investment. This is especially helpful for Indian startups working with limited budgets. Faster design revisions mean toys can be fine-tuned based on feedback before large-scale marketing, saving time and reducing risk.

Future Outlook — What’s Next for 3D-Printed Toys

The future of 3D printed toys includes exciting possibilities. Multi-material and full-colour printing will enable more interactive and visually appealing designs. Toys embedded with electronics for smart play are already in development stages globally. Sustainability will also play a big role, with PLA and recycled materials being explored for eco-friendly toy production. Indian service providers who invest in these next-gen capabilities will be well-positioned for the future.

A Playground of Possibilities

3D printing has changed who can create toys and how quickly they can bring ideas to market. For Indian 3D printing service providers, this is a golden opportunity to work closely with designers, educators, and product startups. Tesseract is proud to support this new wave of toy innovation with cutting-edge printing technology, helping India build a stronger, more creative toy industry for generations to come.