Medical Technology

Revolutionising Healthcare with 3D Printing

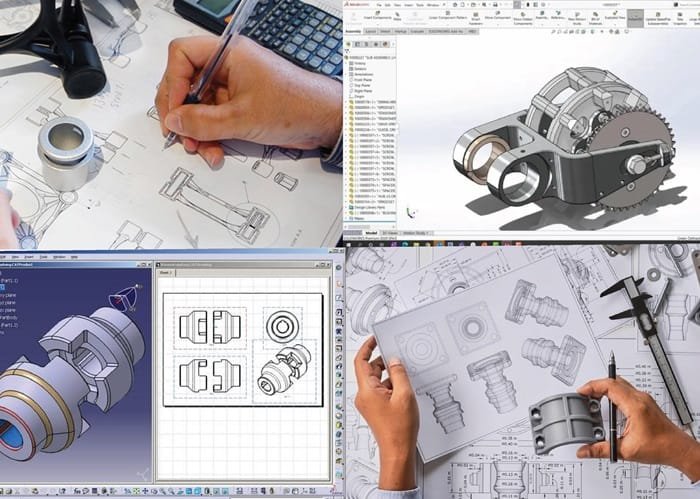

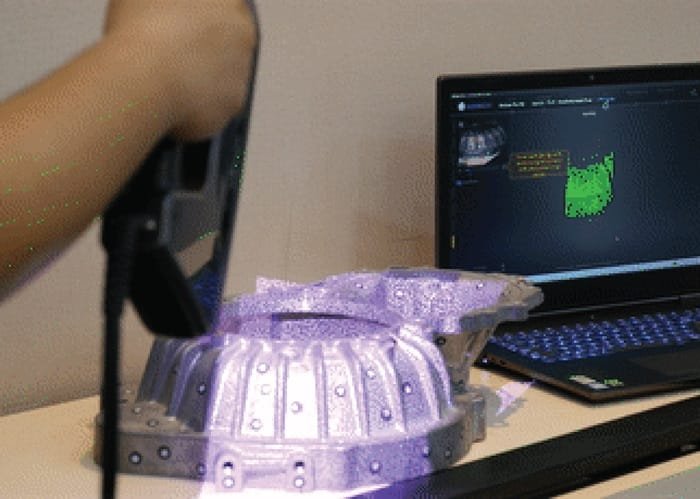

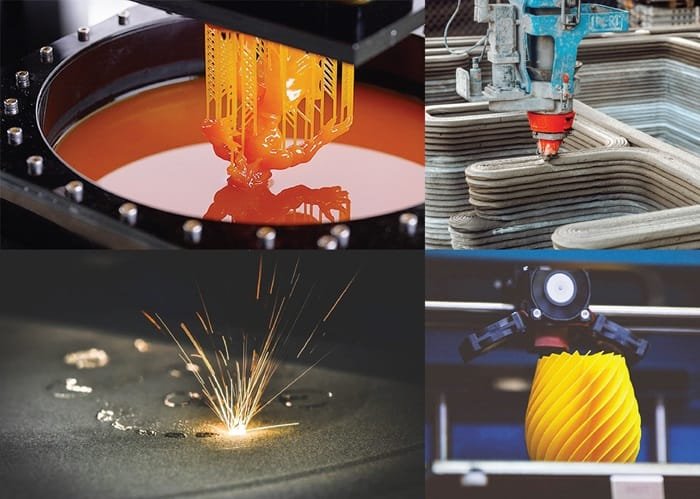

Additive manufacturing (commonly known as 3D printing) has showcased remarkable effectiveness in diverse medical applications, supported by numerous successful case studies. This technology enables the swift production of medical devices, addressing the urgent needs of patients. From prosthetics to surgical guides, 3D Printing offers a flexible and cost-effective solution for crafting custom devices for individual patients. The materials also comply with Biocompatibility Certifications such as USP Class VI and ISO 10993 supporting Eto and Gamma Sterilisation methods. Advanced design softwares can transform medical imaging, such as CT and MRI scans, into precise 3D models, facilitating the creation of accurate and tailored medical devices that perfectly match the patient’s needs.

Applications

- Medical Devices: Creating a wide range of specialised equipment designed to address various healthcare needs, from diagnostic tools to treatment devices.

- Prosthetics: Crafting casts and fully-functional replacement limbs to improve mobility and enhance the quality of life for patients.

- Surgical Guides: Producing precise surgical guides that aid surgeons during complex procedures, ensuring accuracy and success.

- Implants: Customising implants that seamlessly integrate with a patient’s anatomy for enhanced medical outcomes.

- Training Equipment: Developing training equipment to assist medical professionals in refining their skills and techniques.